A nozzle connecting device for spraying equipment

A technology for connecting devices and spraying equipment, applied in the direction of spraying devices, etc., can solve problems such as limited control effect, inability to adjust, affect spraying effect, etc., and achieve the effect of convenient maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

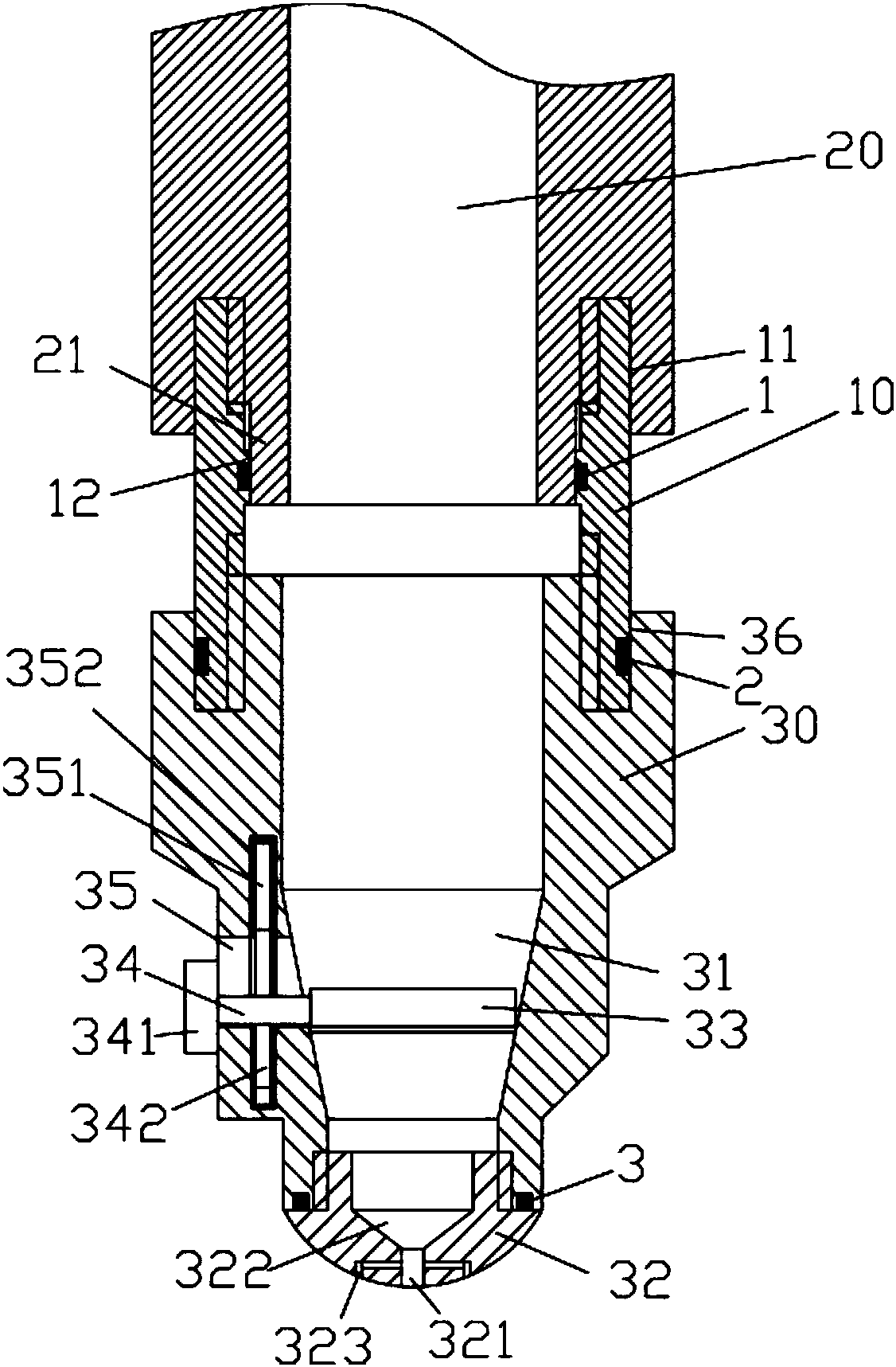

[0015] Examples, see e.g. figure 1 As shown, a spray head connection device for spraying equipment includes a spray head intermediate connecting pipe 10, the upper end of the spray head intermediate connecting pipe 10 is screwed with a delivery pipe 20, and the lower end of the spray head intermediate connecting pipe 10 is screwed with a spray head body 30, the spray head Inside the lower end of the body 30 is a conical cavity 31, the lower end of the nozzle body 30 is screwed with a nozzle 32, an adjustment block 33 is placed in the conical cavity 31, and a connecting rod 34 is fixed on the side wall of the adjustment block 33, the connecting rod 34 is inserted into the adjustment channel 35 on the side wall of the nozzle body 30, the outer end of the connecting rod 34 is fixed with a moving block 341, the moving block 341 is close to the outer side wall of the nozzle body 30, and the inner side wall of the adjustment channel 35 There is an adjustment slot 351 in the middle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com