Calcium carbonate D3 granules and preparation method thereof

A technology of calcium carbonate and granules, which is applied in the direction of pharmaceutical formulations, active ingredients of aluminum/calcium/magnesium, and medical preparations of non-active ingredients, etc. The stability of D3 granules is not good, and the curative effect of calcium carbonate D3 granules is unstable, etc., to achieve the effect of stable and controllable product quality, low cost, and not easy to deteriorate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

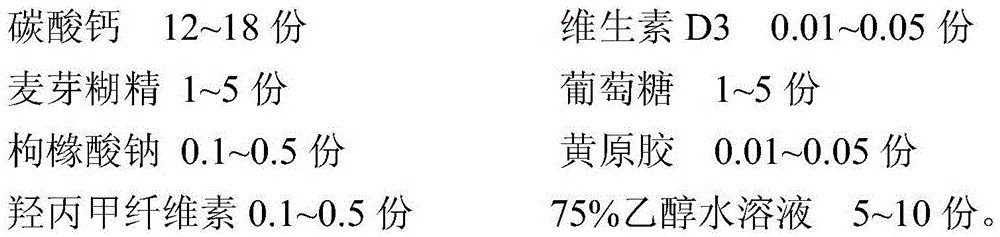

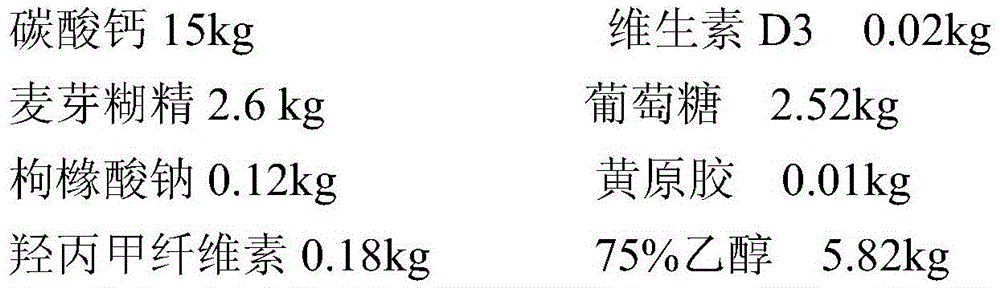

[0028]

[0029] Steps:

[0030] (1) Dissolve hypromellose in 1 / 2 of the prescription volume of 75% ethanol aqueous solution, then add 1 / 2 of the prescription volume of calcium carbonate and mix evenly, set aside.

[0031] (2) Pour the remaining calcium carbonate, maltodextrin, glucose and sodium citrate into a mixer and mix, then add the raw materials in step (1) and mix evenly to obtain a mixture;

[0032] (3) Granulation: dissolving vitamin D3 and xanthan gum in the remaining 75% ethanol to prepare a binder. Mix with the above mixture to make a soft material, dry at 50°C for 3 hours after granulation, granulate, and pack separately to obtain calcium carbonate D3 granules.

Embodiment 2

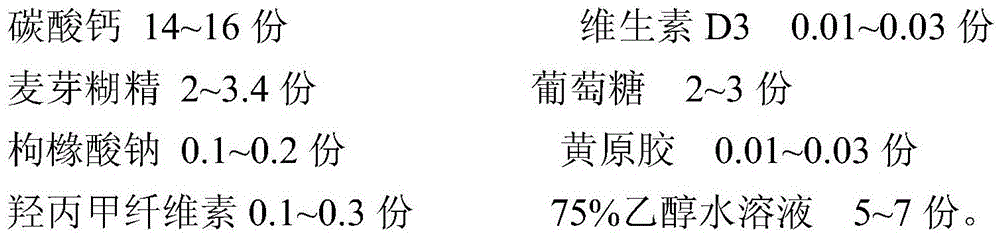

[0034]

[0035] Steps:

[0036] (1) Dissolve hypromellose in 1 / 2 of the prescription volume of 75% ethanol solution, then add 1 / 2 of the prescription volume of calcium carbonate and mix evenly, set aside.

[0037] (2) Pour the remaining calcium carbonate, maltodextrin, glucose and sodium citrate into a mixer and mix, then add the raw materials in step (1) and mix evenly to obtain a mixture;

[0038] (3) Granulation: dissolving vitamin D3 and xanthan gum in the remaining 75% ethanol to prepare a binder. Mix with the above mixture to make a soft material, dry at 40°C for 4 hours after granulation, granulate, and pack separately to obtain calcium carbonate D3 granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com