Variable-displacement swash-plate-type compressor

A variable type, swash plate type technology, applied in the direction of liquid variable volume machinery, mechanical equipment, machine/engine, etc., can solve the problems of pressure leakage, difficult to change the discharge volume, unstable posture of the movable body, etc., to achieve full controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

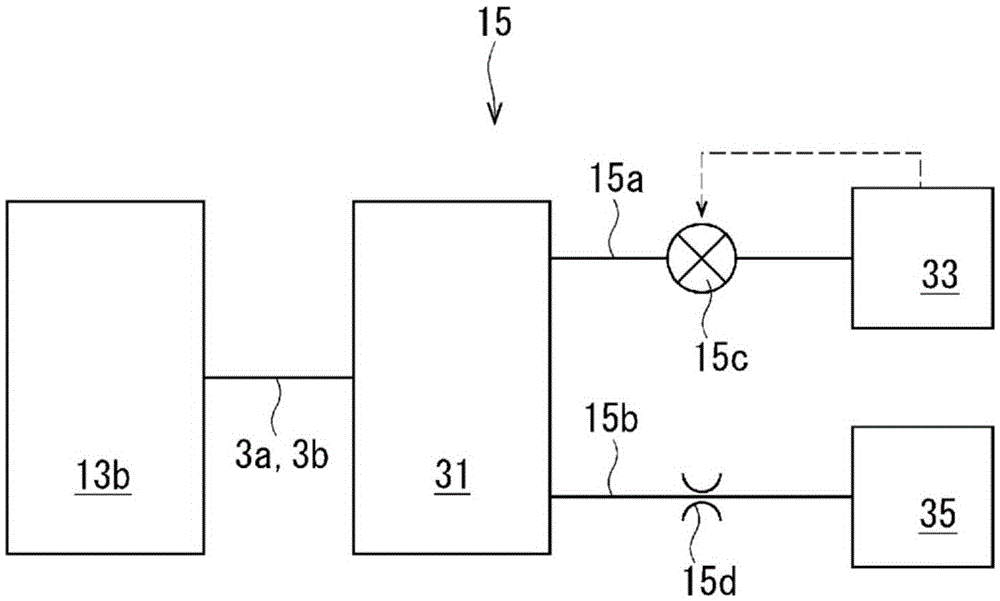

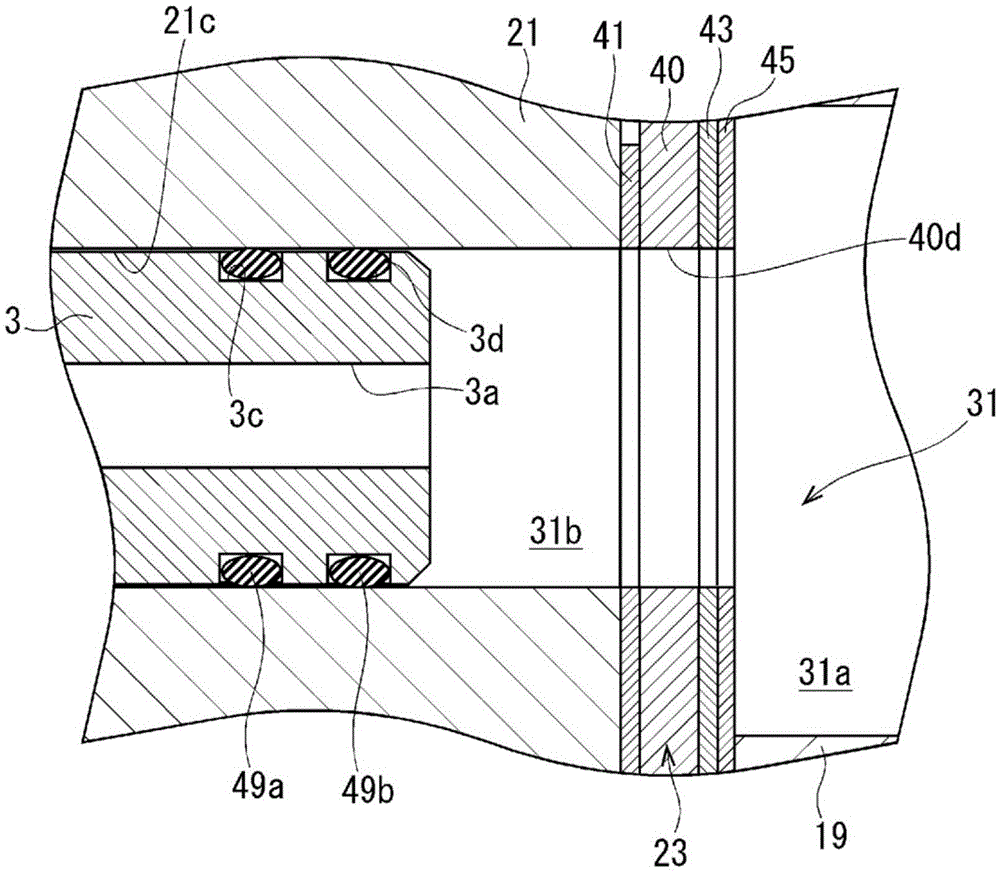

[0059] Such as figure 1 As shown, the compressor of Embodiment 1 has: a housing 1; a drive shaft 3; a swash plate 5; a connecting rod mechanism 7; a plurality of pistons 9; a plurality of pairs of sliding shoes 11a, 11b; figure 2 The control mechanism 15 is shown. Also, for the sake of illustration, in figure 1 In the illustration, the shape of the swash plate 5 is partially simplified. about the latter Figure 7 , Figure 10 Also the same.

[0060] Such as figure 1 As shown, the housing 1 has: a front housing 17 located in front of the compressor; a rear housing 19 located at the rear of the compressor; a cylinder block 21 located between the front housing 17 and the rear housing 19; and a valve unit twenty three.

[0061] The front housing 17 has a front wall 17a extending in the vertical direction of the compressor at the front, and a peripheral wall 17b integrally formed with the front wall 17a and extending from the front of the compressor toward the rear. The fr...

Embodiment 2

[0124] Such as Figure 11 As shown, in the compressor of Embodiment 2, the swash plate 5 has a swash plate main body 50 , swash plate arms 5 e , 5 f , and a contact member 59 . This contact member 59 is also equivalent to the acted part of this invention.

[0125] The contact member 59 is formed separately from the swash plate main body 50 . The contact member 59 is mounted between the swash plate arms 5e, 5f on the front surface 5a of the swash plate main body 50, and is located eccentrically from the drive axis O toward the top dead center corresponding portion T of the swash plate 5.

[0126] A convex portion 59 a protruding forward is formed on the contact member 59 . This convex portion 59a is formed in a substantially hemispherical shape. The convex portion 59a is in point contact with the action surface 134a of the action portion 134 at the action position F. As shown in FIG. Thus, in this compressor, the action portion 134 abuts on the contact member 59 at a positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com