Test method and test device for asphalt pavement crack load response relative displacement

A crack load, relative displacement technique

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

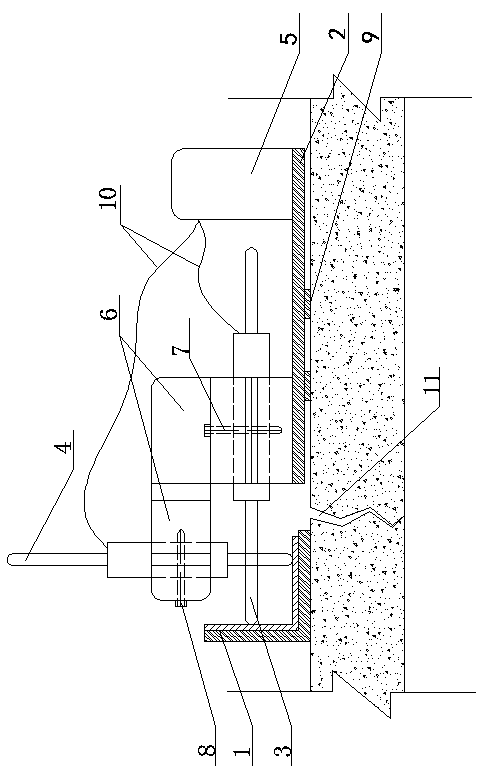

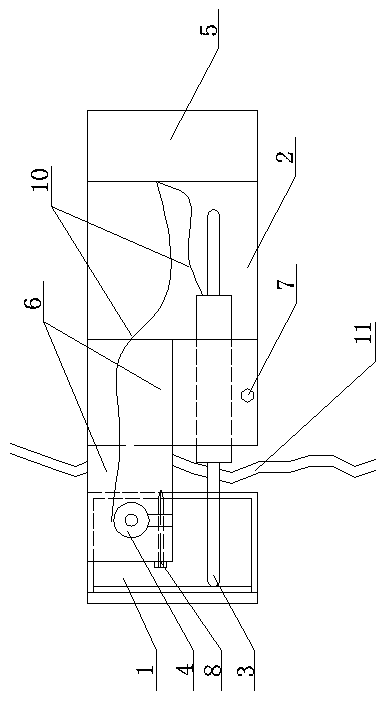

[0032] as attached figure 1 , 2 As shown, the asphalt pavement crack load response relative displacement test device of the present invention is mainly composed of a reference part 1, a sensor positioning part 2, a horizontal linear displacement sensor 3, a vertical linear displacement sensor 4, a controller 5 and a bracket 6. Wherein, the sensor positioning part 2, the horizontal linear displacement sensor 3, the vertical linear displacement sensor 4 and the controller 5 constitute a sensor system.

[0033] The reference member 1 is an "L"-shaped component composed of a vertical plate and a horizontal plate, and the vertical plate and the horizontal plate are perpendicular to each other. The vertical surface and the horizontal surface inside the reference member 1 are smooth and flat, and are used for contacting with the measuring end of the sensor.

[0034] The sensor positioning part 2 is flat, the bracket 6 is fixed on the front end of the sensor positioning part 2, and ...

Embodiment 2

[0039] The specific implementation steps of the load response relative displacement test method for asphalt pavement cracks are as follows:

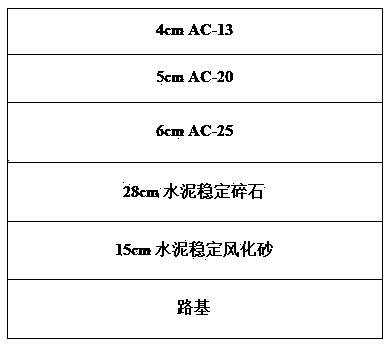

[0040] (1) Select a straight pavement transverse joint 11, the original pavement structure is as attached image 3 shown;

[0041] (2) Detect and record the surface temperature of the crack road at 25°C;

[0042] (3) Select a relatively straight section of the crack 11, and fix the reference piece 1 of the test device described in Example 1 to one side of the crack 11 by superglue. The fracture measurement section is parallel;

[0043] (4) Fix the sensor system of the test device on the other side of the crack 11 with super glue, make the lower edge of the sensor positioning part 2 parallel to the crack 11 and align with the reference part 1, and the vertical distance from the lower edge to the crack 11 is 1 cm. It is required that the connection line between the sensor positioning part 2 and the reference part 1 is perpendicular to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com