Bituminous mixture compaction simulation method based on discrete elements

An asphalt mixture and simulation method technology, applied in CAD numerical modeling, special data processing applications, instruments, etc., can solve problems such as the inability to truly reflect the compaction mechanism of asphalt mixture, and achieve the effect of strong practicability and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

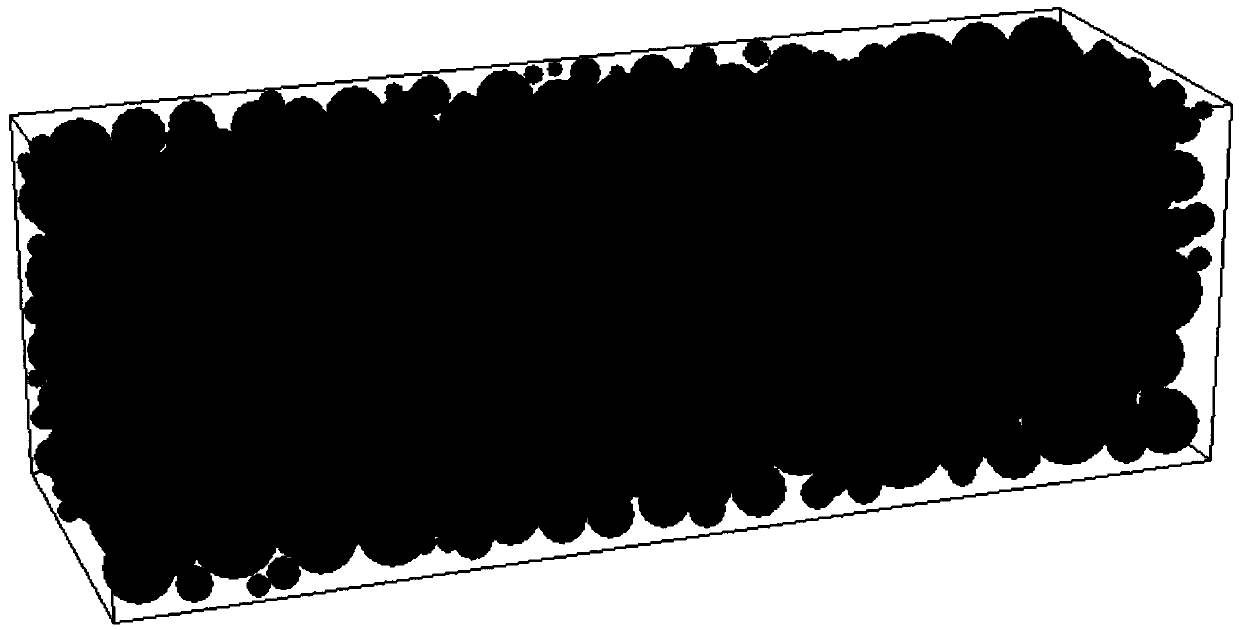

[0037] Take the compaction of asphalt mixture SMA13 as an example and describe the implementation steps of the present invention in detail in conjunction with the accompanying drawings. The gradation of asphalt mixture SMA13 is shown in Table 1.

[0038] Table 1 Grading table of asphalt mixture SMA13

[0039]

[0040] The specific asphalt mixture modeling process is as follows:

[0041] 1) Determination of the space area

[0042] According to Table 1, the percentage of coarse aggregate (greater than or equal to 2.36 mm) in the asphalt mixture is dominant, and the percentage of fine aggregate (less than 2.36 mm) is small, but due to its small size, the number of particles is small. far more than the amount of coarse aggregate. According to the dispersion theory of asphalt mixture, asphalt mixture is regarded as a multiphase composite material composed of coarse aggregate, asphalt mortar (fine aggregate and asphalt) and porosity from the macroscopic scale. In addition, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com