A Continuous Position Recognition Device for Microscope

A technology for identifying devices and microscopes, applied in the field of microscopes, can solve the problem of Hall sensors not being able to sense signals, etc., and achieve the effects of being unaffected by distance, not limited by size, and having high signal sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

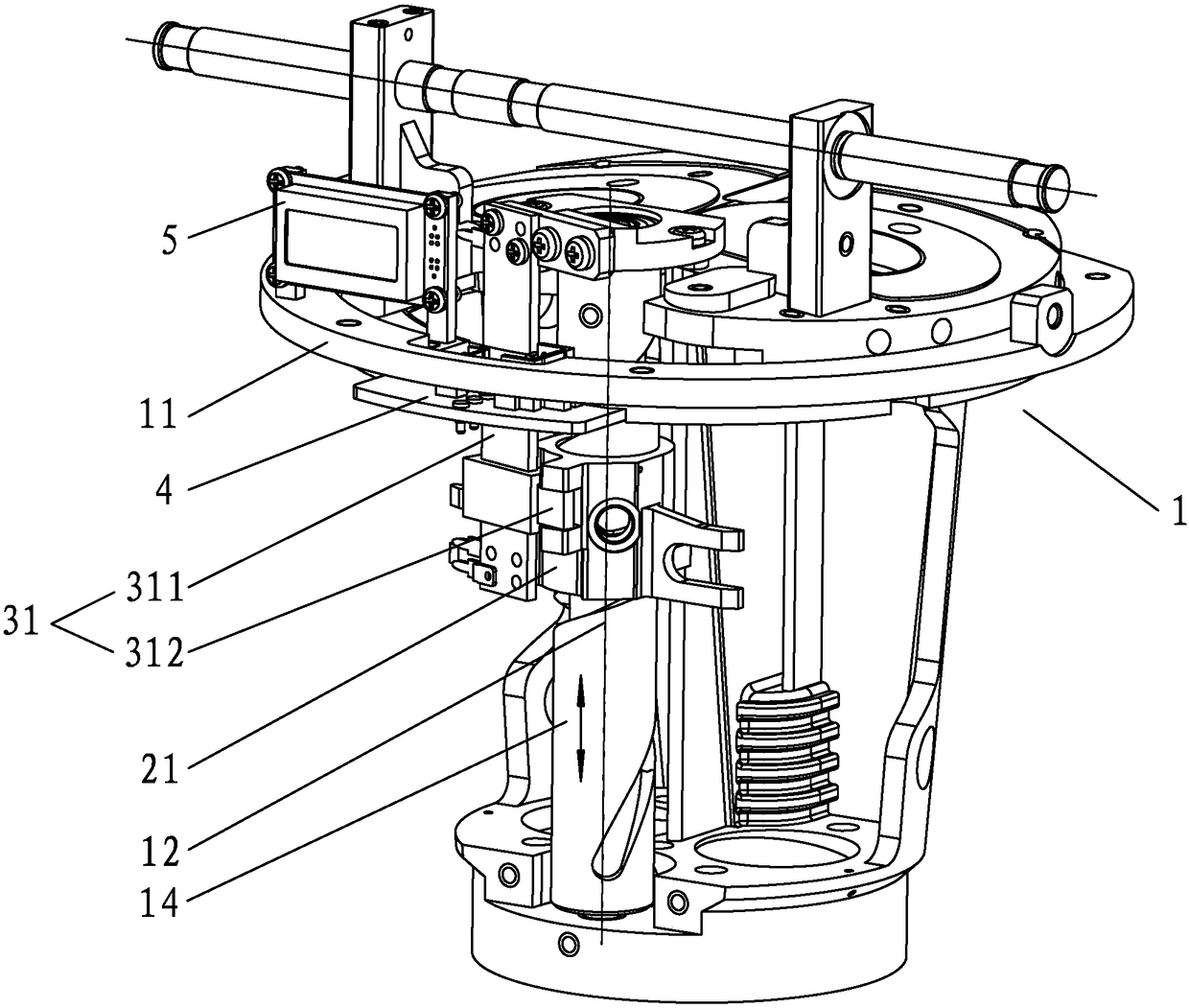

[0024] like figure 1 As shown, a continuous position recognition device for a microscope includes a frame 1 , a working position switching mechanism, a potentiometer, a control circuit 4 and an additional display device 5 . The working position switching mechanism in this embodiment is a zoom guide sleeve 21, the potentiometer is a straight slide potentiometer 31, and the additional display device 5 is a liquid crystal display module.

[0025] The main frame includes a horizontally arranged main board 11 and a vertical shaft 14 vertically fixed on the lower surface of the main board 11 . The variable magnification guide sleeve 21 is movably connected with the vertical shaft and can perform continuous linear movement along a vertical axis 12 of the vertical shaft 14 . The straight-slide potentiometer 31 includes a straight-slide potentiometer body 311 and an intermediate tap slide bar 312. The straight-slide potentiometer main body 311 is vertically installed on the lower surf...

Embodiment 2

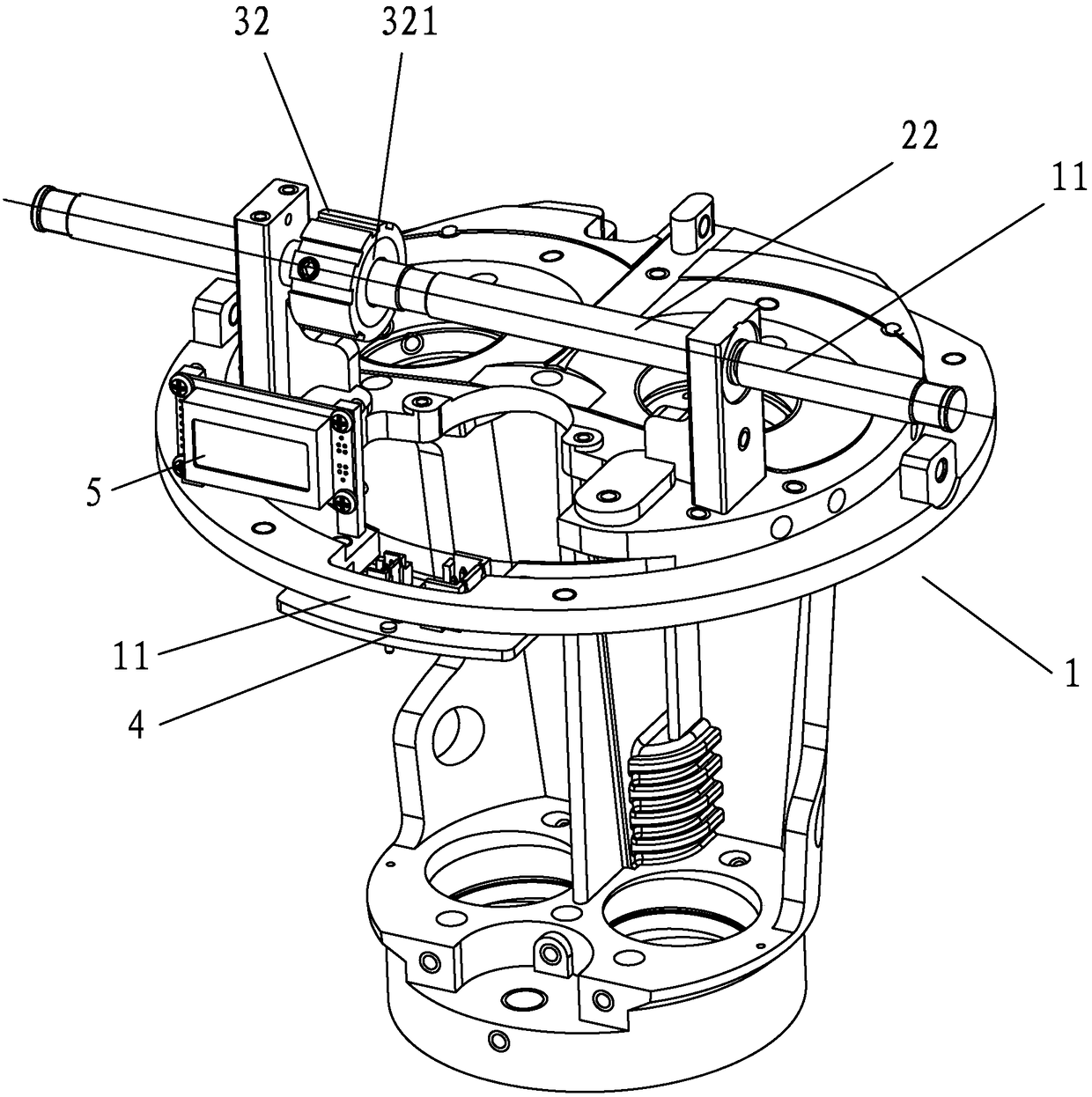

[0029] like figure 2 As shown, a continuous position recognition device for a microscope includes a frame 1 , a working position switching mechanism, a potentiometer, a control circuit 4 and an additional display device 5 . The working position switching mechanism of this embodiment is the zoom handwheel shaft 22, the potentiometer is a rotary potentiometer 32, and the additional display device 5 is an LED.

[0030] The main frame includes a horizontally arranged main board 11 . The zoom handwheel shaft 22 is horizontally installed on the bracket on the upper surface of the main board 11 , and the zoom handwheel shaft 22 can perform continuous linear rotation along a horizontal axis 13 of the zoom handwheel shaft 22 . The middle tap 321 of the rotary potentiometer 32 is coaxially fixedly connected with the zoom handwheel shaft 22 , and the middle tap 321 of the rotary potentiometer 32 can perform synchronous and continuous rotational movement with the zoom handwheel shaft 22...

Embodiment 3

[0034] In this embodiment, on the basis of Embodiment 1, the control circuit 4 is connected to the light source brightness control unit of the microscope. Set different light source brightness for different working positions; when the microscope observer switches to a certain working position of the continuous zoom microscope for the first time, the brightness of the lighting source is adjusted according to the magnification requirements of the working position. After the adjustment, the control The circuit will immediately store the brightness of this position in the memory according to the change of the resistance value of the potentiometer. The stored brightness of the working position. That is, when the working position of the working position switching mechanism changes, the control circuit (4) can automatically adjust the brightness of the light source according to the brightness data of the light source stored in the memory.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com