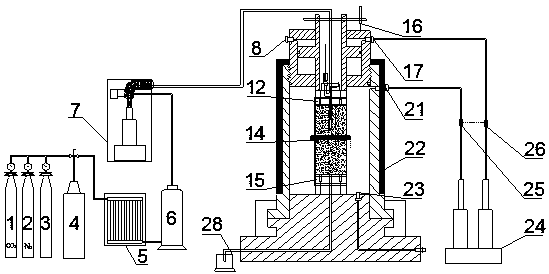

A Coal Rock Multiphase Different Fluid Triaxial Fracturing Test Device and Test Method

A fracturing test and triaxial pressure technology, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve problems such as comparison of fracturing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0028] Implementation Mode 1: Taking the Φ75×150mm coal rock specimen as an example, the pressurization rate is compared with the CO 2 Gas fracturing, CO 2 Liquid fracturing, supercritical CO 2 Comparative research experiment of fracturing and hydraulic fracturing; the specific experimental steps are as follows:

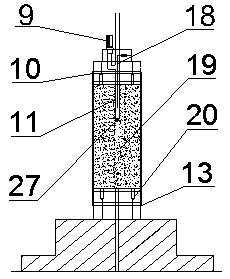

[0029] Step 1: Process the coal and rock specimens with high-precision CNC wire cutting equipment to obtain raw coal and rock specimens of Φ75×150 mm, and use a high-precision drilling machine bench drill to drill holes on the end face of the dried specimens with a diameter of Φ15 mm. The depth is 75mm;

[0030] Step 2: Seal the middle and upper part of the fracturing pipe 11 with a high-temperature sealant to the central hole contained in the coal-rock test piece 19, and then attach the upper and lower sets of acoustic emission sensors 20 to the coal-rock test piece 19 and fix them on the upper pressure head 12 1. In the acoustic emission hole reserved by the low...

Embodiment approach 2

[0037] Embodiment 2: Taking Φ75×150mm coal and rock specimens as an example, the supercritical CO 2 The research and comparison of fracturing effects, the specific research steps are: repeat the experimental steps 1, 2, 3, 7, and 8 in Embodiment 1, and at step 7, adjust the supercritical CO 2 The pressure and temperature of the fracturing medium are used to change its viscosity, so that the viscosity of the supercritical CO 2 Research and comparison experiment of fracturing effect.

Embodiment approach 3

[0038] Implementation Mode 3: Taking the Φ75×150mm coal rock specimen as an example, the CO 2 Gas fracturing, liquid CO 2 Fracturing, supercritical CO 2 The research and comparison of fracturing effects such as fracturing and hydraulic fracturing, the specific experimental steps are: repeat all the experimental steps in Embodiment 1, and change the flow rate control at 30ml / min, 50ml / min, 100ml / min to pass The heating part in the refrigerator 5 and the temperature increasing and boosting integrated device 7 is used to regulate the temperature of the fracturing medium, so as to control the temperature of the medium temperature on the supercritical CO 2 Research and comparison experiment of fracturing effect.

[0039] To sum up, the present invention is mainly used for comparative tests of fracturing of different fluids in multiphase states and conditions of coal rock specimens.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com