Drilling liner hanger and string type well cementing system comprising same

A technology of liner hanger and core pipe, which is applied in the direction of wellbore/well components, earthwork drilling and production, etc. It can solve the problems of high circulation pressure, prolong the time of cementing operation, reduce the efficiency of deblocking, etc., and achieve shortened time, The effect of accelerating unblocking efficiency and improving unblocking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

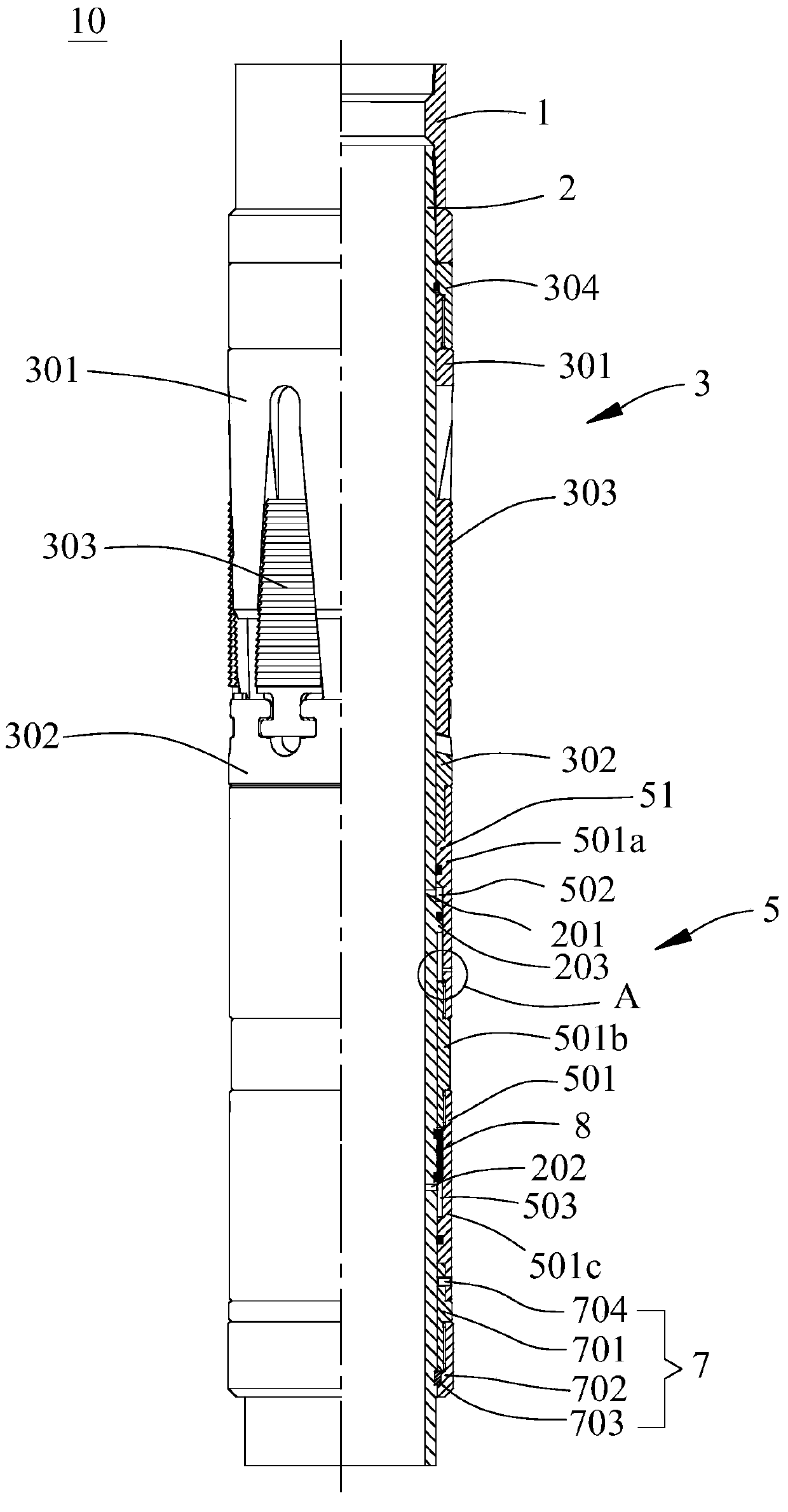

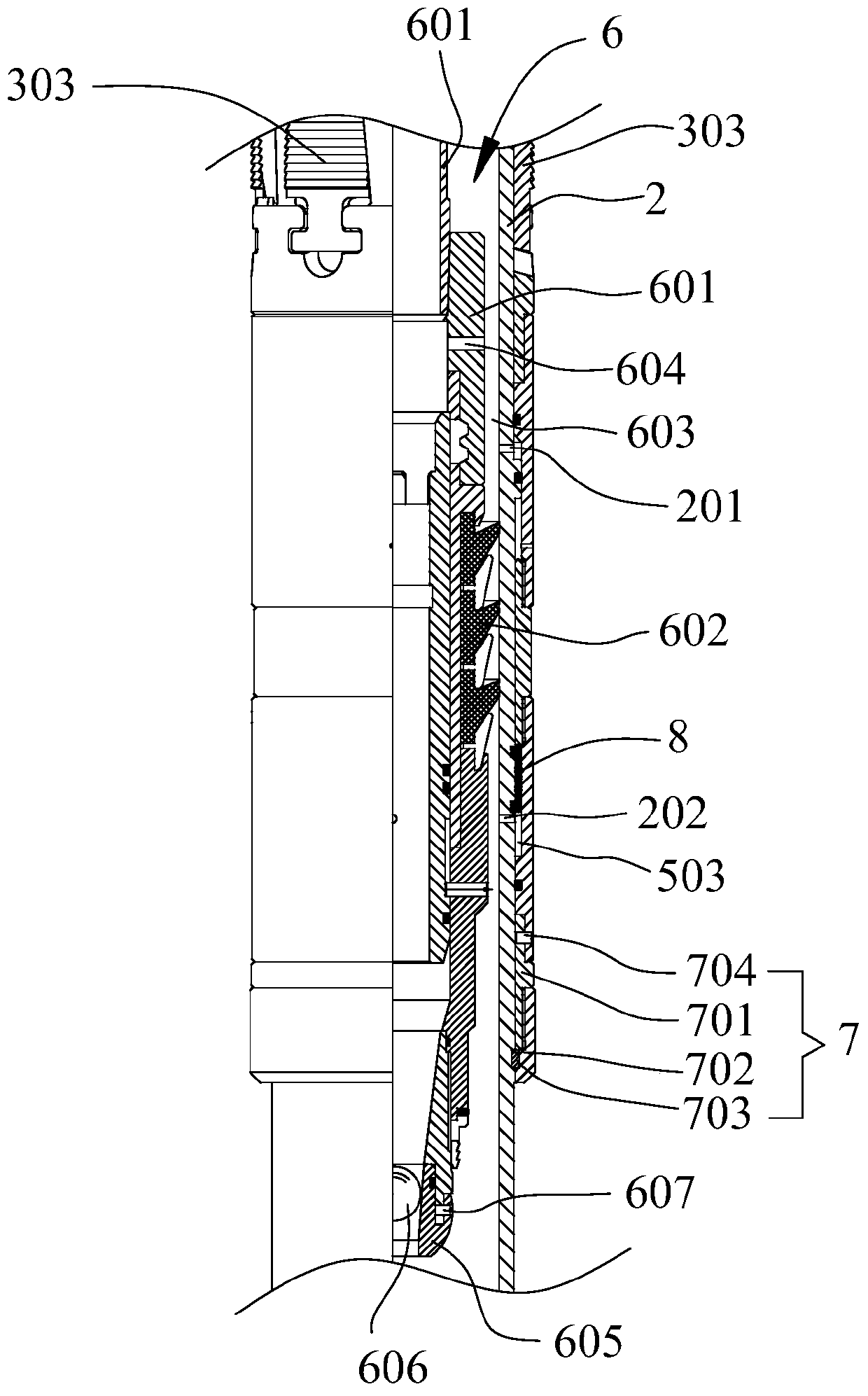

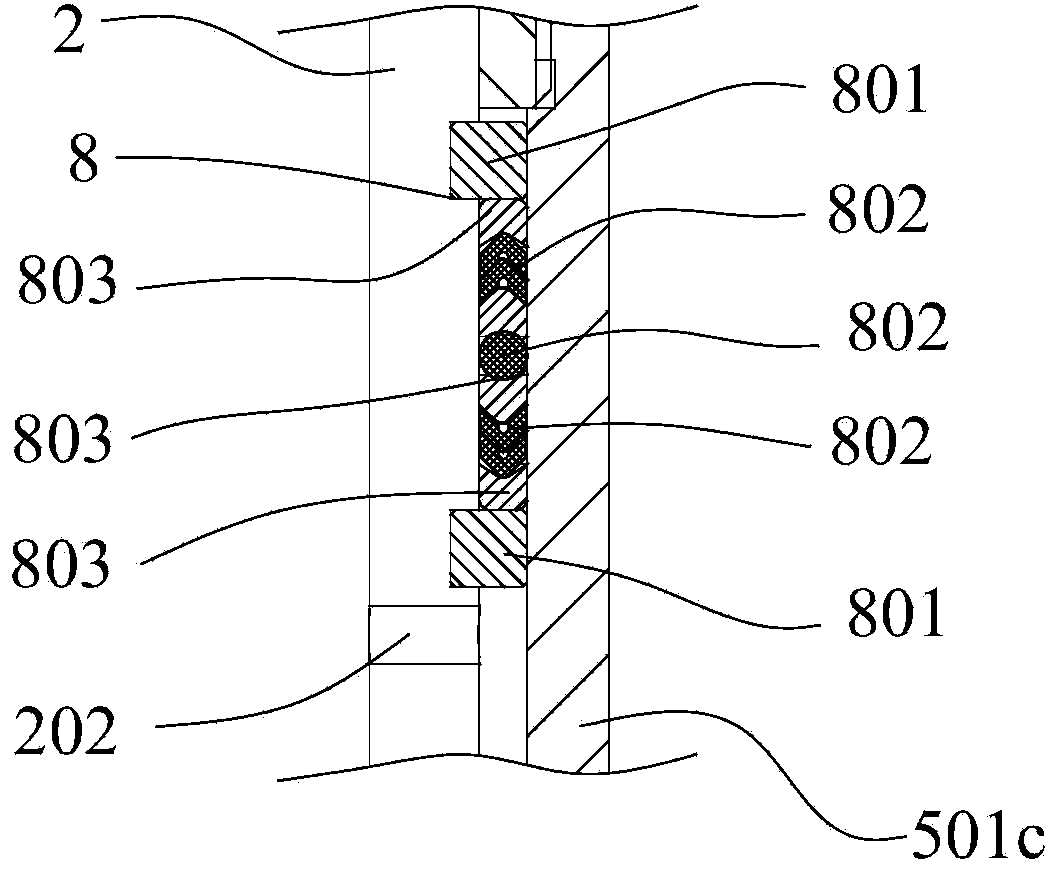

[0026] According to the first aspect of the present invention, a liner hanger 10 is provided, which is used for setting and hanging a liner or liner string on the inner wall of an oil well casing. Such as figure 1 As shown, the liner hanger 10 includes a core pipe 2 . The upstream end of the core pipe 2 can be connected and fixed with the packer through the threaded joint 1, and the downstream end can be used to connect the liner or the liner string. The core tube 2 has two axially spaced pressure transmitting holes 201 and a pressure stabilizing hole 202 . Wherein, the above-mentioned packer and liner are well known to those skilled in the art, and will not be described in detail here.

[0027] According to the present invention, the liner hanger 10 includes a mounting mechanism 3 sleeved outside the core pipe 2 . The sitting and hanging mechanism 3 is preferably a sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com