Mulberry and bamboo composite fiber grafted with modified mulberry fiber and bamboo fiber in ionic liquid and preparation method thereof

An ionic liquid, graft modification technology, applied in the chemical post-treatment of fibers, fiber treatment, cellulose/protein conjugated rayon and other directions, can solve the problem of low dissolution efficiency of mulberry fiber and bamboo fiber, Fiber composite fibers have low efficiency and poor performance, which can solve the problem of shortage of raw materials, abundant raw materials, and mild and easy-to-control reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

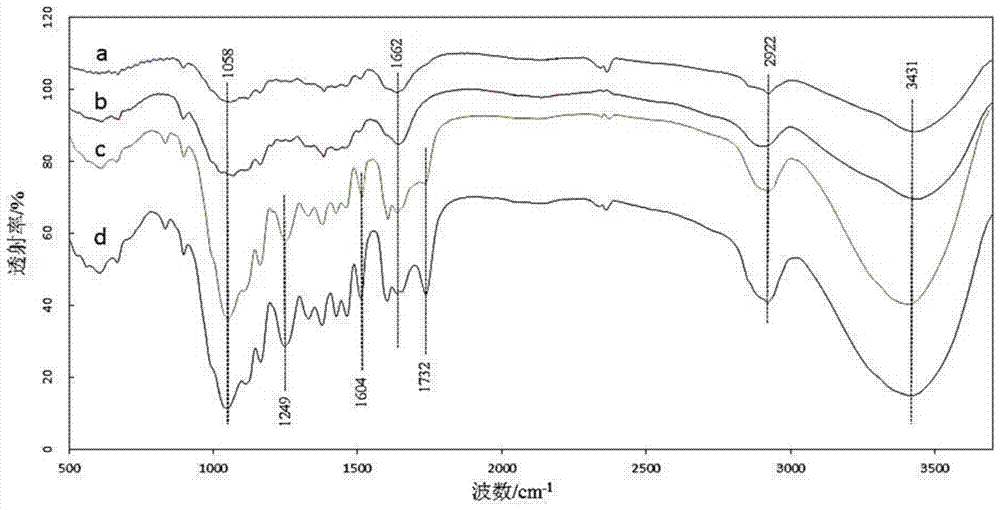

Image

Examples

Embodiment 1

[0030] (1) Take mulberry branches and use a knife to remove the bark of mulberry branches and cut them into 2-3cm pieces, take bamboo branches and cut them into 2-3cm pieces with a knife, wash them with tap water, and dry them at 80°C for 24 hours.

[0031] (2) The truncated mulberry branches and bamboo branches were respectively pulverized with a traditional Chinese medicine pulverizer, and then ball-milled with a planetary ball mill at a rate of 100 r / min for 2 hours, and dried at 80° C. for 2 hours to obtain mulberry branch powder and bamboo branch powder.

[0032] (3) Add 2 g of mulberry branch powder and bamboo branch powder to 100ml beaker (a) and beaker (b) respectively, add 120 g / L NaOH solution to the two beakers at a bath ratio of 1:50 to 100 and stir rapidly uniform.

[0033] (4) Seal the above two beakers, place them in an ultrasonic cleaning machine filled with water, and ultrasonicate for 1-2 hours at a temperature of 50°C.

[0034] (5) Wash the mulberry branch ...

Embodiment 2

[0038] (1) Peel the mulberry branches with a knife and cut them into 2-3cm pieces, take the bamboo branches and cut them into 2-3cm pieces with a knife, wash them with tap water, and dry them at 80°C for 24 hours.

[0039] (2) The truncated mulberry branches and bamboo branches were respectively pulverized with a traditional Chinese medicine pulverizer, and then ball milled with a planetary ball mill at a rate of 100 r / min for 2 hours, and dried at 80° C. for 2 hours to obtain mulberry branch powder and bamboo branch powder.

[0040] (3) Add 2g each of mulberry powder and bamboo powder into 100ml beaker (a) and beaker (b), add 120g / L NaOH solution into the two beakers according to the bath ratio of 1:50-100 and stir quickly evenly .

[0041] (4) Seal the above two beakers, place them in an ultrasonic cleaning machine filled with water, and ultrasonicate for 1-2 hours at a temperature of 50°C.

[0042] (5) Wash the mulberry powder and bamboo powder after ultrasonic-assisted Na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com