Cylinder type annealing furnace

An annealing furnace and caisson technology, which is applied in the direction of furnaces, furnace types, heat treatment furnaces, etc., can solve the problems of reducing work efficiency and increasing heating time, and achieves the effects of thorough annealing, uniform heating, and better annealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

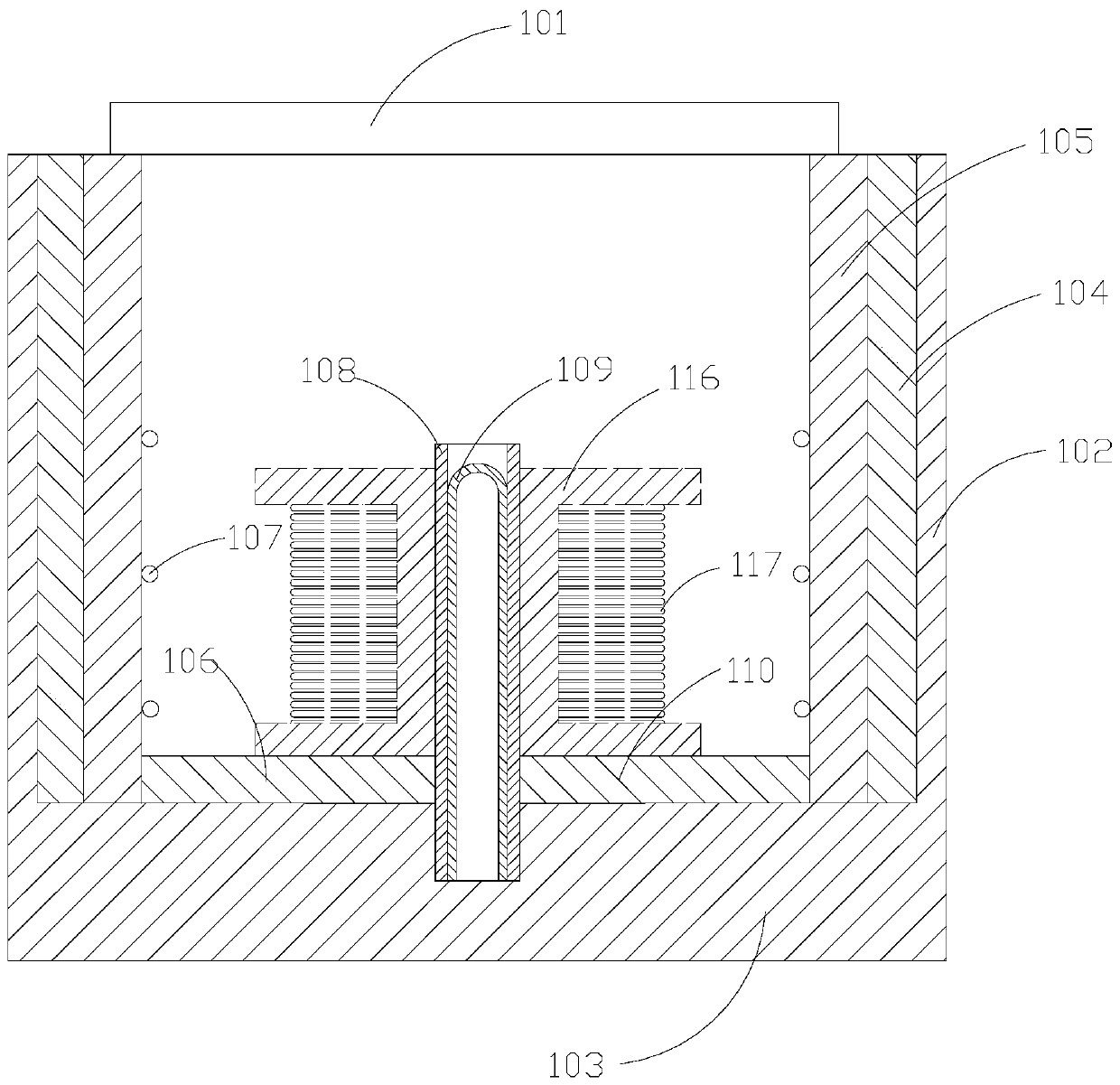

[0042] Embodiment 1, with reference to Figure 1 to Figure 3

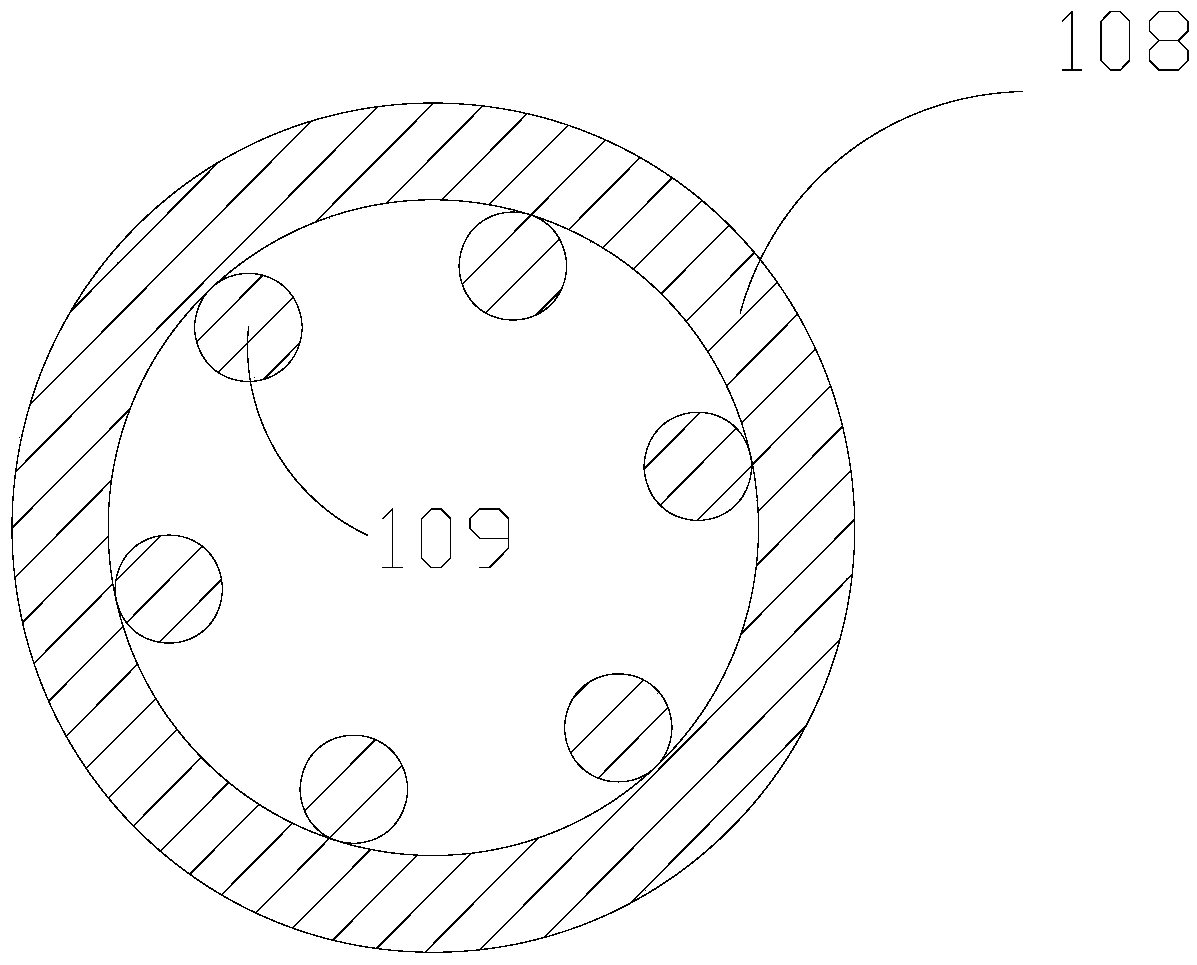

[0043] Such as figure 1 As shown, a caisson type annealing furnace includes a furnace body and a furnace cover 101, the furnace body includes a furnace side wall 102 and a furnace bottom wall 103, the furnace side wall 102 is provided with a first thermal insulation lining 104, the The first thermal insulation lining 104 is provided with a refractory lining 105, the furnace cover 101 is covered on the first thermal insulation lining 104, the upper surface of the furnace bottom wall 103 is provided with a second thermal insulation lining 106, and the refractory lining 105 is provided with a first resistance wire 107, and the furnace body is provided with a vertical cylinder 108, and a second resistance wire 109 is provided in the vertical cylinder 108.

[0044] When the aluminum conductor 117 is annealed, the aluminum conductor 117 is wound on the "I" shaped annealing disk 116, and the annealing disk 116 is put in...

Embodiment 2

[0051] Embodiment 2, with reference to Figure 4 to Figure 6

[0052] The implementation principles and technical effects of the device provided by the embodiment of the present invention are the same as those of the foregoing method embodiment. For brief description, for the parts not mentioned in the device embodiment, reference may be made to the corresponding content in the foregoing method embodiment.

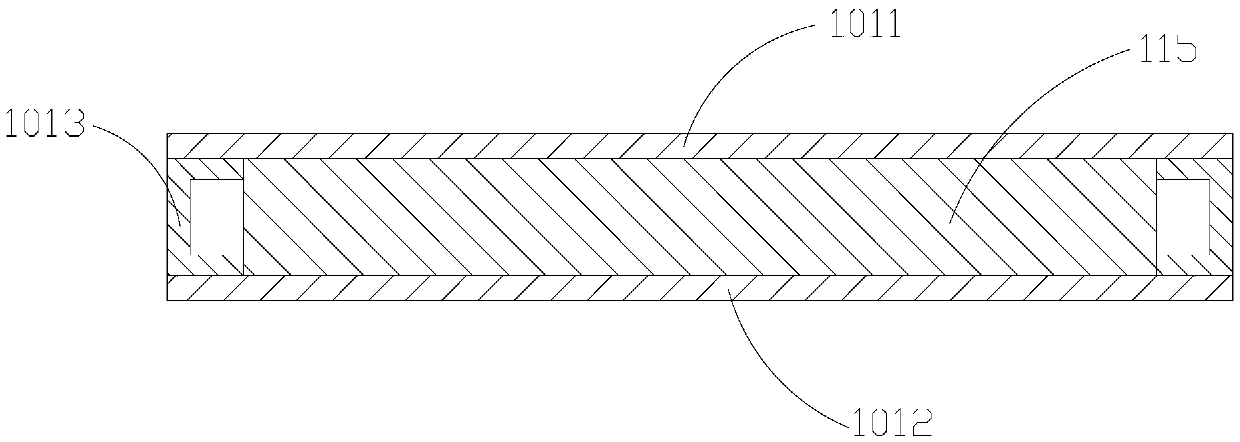

[0053] In this embodiment, the furnace body is also provided with a turntable 110, such as Figure 5 As shown, the turntable 110 is in the shape of "I" as a whole. The turntable 110 includes a base 1101 and a disc 1102. The base 1101 is a T-shaped structure. The disc 1102 is screwed to the base 1101. The bottom of the base 1101 is provided with It is located in the bottom wall of the furnace body and can rotate around its own axis.

[0054] Such as Figure 4 As shown, a motor 111 is arranged in the bottom wall of the furnace body, the output shaft of the motor 111 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com