A method of extracting bay leaf oil from bay leaves with subcritical n-butane fluid

A n-butane and subcritical technology, which is applied in the direction of essential oils/fragrances, fat production, etc., can solve the problems of unfavorable product properties, rough process, and broken products, and achieve high recycling efficiency, complete extraction components, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

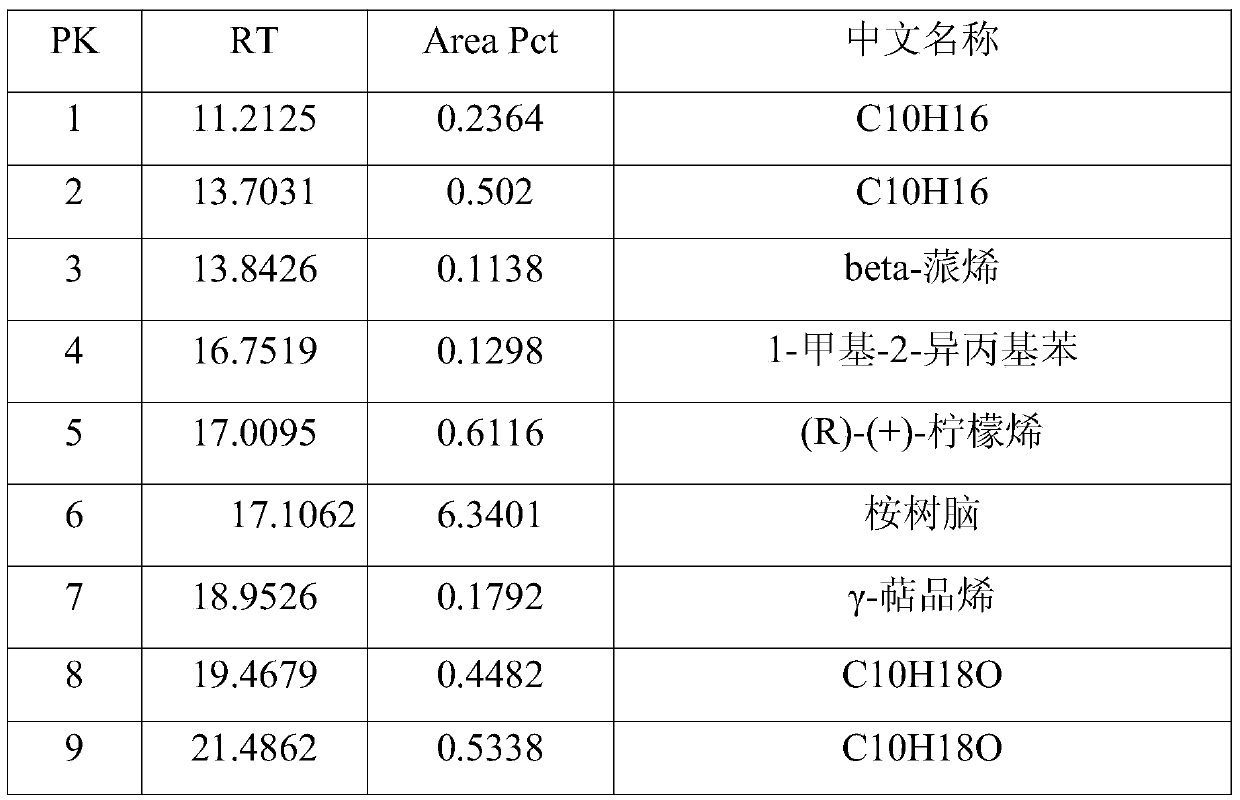

Examples

Embodiment 1

[0039] A method for extracting geranium oil from geranium leaves with subcritical n-butane fluid, comprising the steps of:

[0040] 1) First dry the cleaned bay leaves at 55±5°C for 2 to 3 hours until the water content is ≤7wt%, crush them to 40 to 60 mesh, then put them into a 300 mesh bag with a volume of 3L, and weigh 50.30 kilogram;

[0041] 2) Put the bag containing the fragrant leaves in step 1) into the extraction tank, seal it, and heat the extraction tank through the water circulation system. When the heating temperature reaches 55°C, evacuate to a vacuum of 0.1MPa , discharge the air in the extraction tank;

[0042] 3) Introduce n-butane solvent into the extraction tank described in step 2) with a plunger pump, add n-butane and bay leaves with a liquid-to-material volume ratio of 1:1, and submerge the bag with the solvent;

[0043] 4) Start the thermal circulating water system, raise the temperature to 55°C for extraction, the extraction pressure is 0.1MPa, the ext...

Embodiment 2

[0048] A method for extracting geranium oil from geranium leaves with subcritical n-butane fluid, comprising the steps of:

[0049] 1) First dry the cleaned fragrant leaves at 55±5°C for 2 to 3 hours until the water content is ≤7wt%, crush them to 40 to 60 mesh, then put them into a 300 mesh bag with a volume of 3L, and weigh 50.50 kilogram;

[0050] 2) Put the material bag containing fragrant leaves and 3.58 kg of soybean oil in step 1) into the extraction tank, seal it, and heat the extraction tank through the water circulation system. When the heating temperature reaches 60°C, pump it to The vacuum degree is 0.5MPa, and the air in the extraction tank is discharged;

[0051] 3) Introduce n-butane solvent into the extraction tank described in step 2) with a plunger pump, add n-butane and bay leaves with a liquid-to-material volume ratio of 2:1, and submerge the bag with the solvent;

[0052] 4) Start the thermal circulating water system, raise the temperature to 60°C for ex...

Embodiment 3

[0057] A method for extracting geranium oil from geranium leaves with subcritical n-butane fluid, comprising the steps of:

[0058] 1) Dry the cleaned fragrant leaves at 55±5°C for 2 to 3 hours until the water content is ≤7wt%, crush them to 40 to 60 mesh, then put them into a 300 mesh bag with a volume of 3L, and weigh 50.10 kg ;

[0059] 2) Put the material bag containing fragrant leaves and 14.43 kg of soybean oil in step 1) into the extraction tank, seal it, and heat the extraction tank through the water circulation system. When the heating temperature reaches 56 ° C, pump To a vacuum of 0.25MPa, discharge the air in the extraction tank;

[0060] 3) Introduce n-butane solvent into the extraction tank described in step 2) with a plunger pump, add n-butane and bay leaves with a liquid-to-solid volume ratio of 1.5:1, and submerge the bag with the solvent;

[0061] 4) Start the thermal circulating water system, raise the temperature to 56°C for extraction, the extraction pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com