Free liquid controlling agent for oil well cement slurry, preparation method and applications thereof

A cementing cement slurry and control agent technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of large amount of liquid silicon addition, achieve less usage, eliminate or reduce free liquid, and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

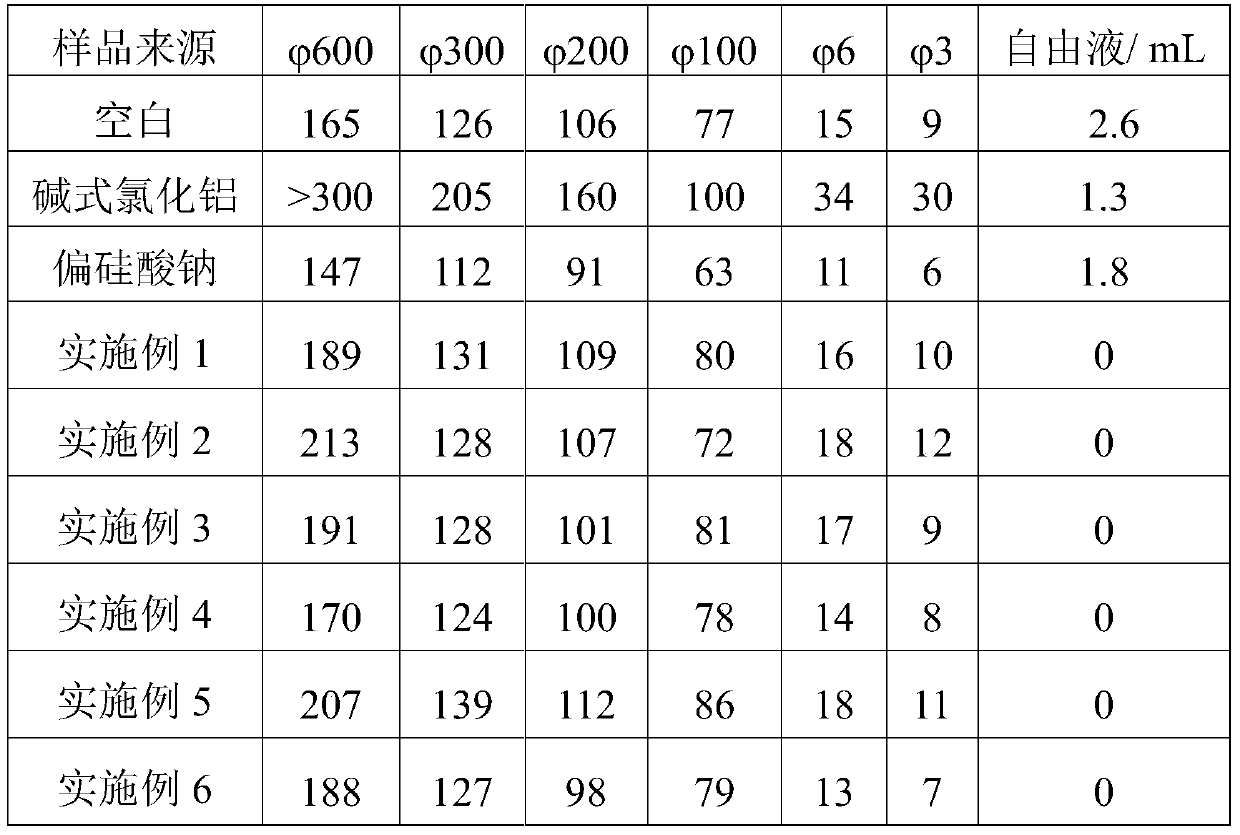

Examples

Embodiment 1

[0035] The raw materials used are as follows:

[0036] The consumption of water is 100g;

[0037] Nano-attapulgite, particle size 20-50nm, dosage 20g;

[0038] Nano silica, particle size 30-100nm, dosage 30g;

[0039] The amount of polycarboxylic acid dispersant is 0.5g;

[0040] The amount of slurry stabilizer hydroxyethyl cellulose is 0.5g;

[0041] Preparation method: mix the above components, stir at high speed (12000±500 rpm), and adjust the pH of the suspension to 9 with NaOH to obtain the free liquid control agent for well cementing slurry of the present invention.

Embodiment 2

[0043] The raw materials used are as follows:

[0044] The consumption of water is 100g;

[0045] Nano-attapulgite, particle size 10-20nm, dosage 10g;

[0046] Nano silica, particle size 20-50nm, dosage 30g;

[0047] The dosage of silane copolymerization dispersant is 1g;

[0048] The amount of slurry stabilizer xanthan gum is 0.5g;

[0049] Preparation method: mix the above components, stir at high speed (12000±500 rpm), and adjust the pH of the suspension to 10 with NaOH to obtain the free liquid control agent for well cementing slurry of the present invention.

Embodiment 3

[0051] The raw materials used are as follows:

[0052] The consumption of water is 100g;

[0053] Nano-attapulgite, particle size 30-100nm, dosage 30g;

[0054] Nano silica, particle size 100-200nm, dosage 30g;

[0055] The amount of silane copolymerization dispersant is 0.5g;

[0056] The dosage of slurry stabilizer Brunei gum is 0.5g;

[0057] Preparation method: mix the above components, stir at high speed (12000±500 rpm), and adjust the pH of the suspension to 9 with NaOH to obtain the free liquid control agent for well cementing slurry of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com