Drilling machine and its tool changing method

A technology of drilling machine and tool holder, which is applied to metal processing machinery parts, clamping, supporting and other directions, can solve the problems of low equipment moving rate, low drilling efficiency, occupying drilling time, etc., and save waiting for replacement. The effect of cutting tool time, improving drilling efficiency and equipment mobilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

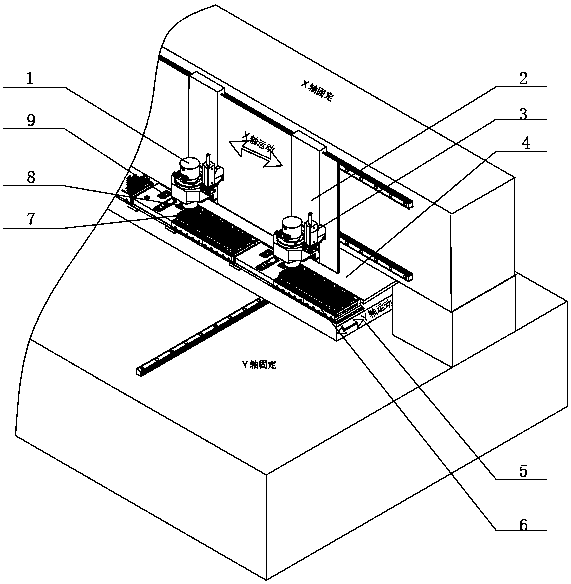

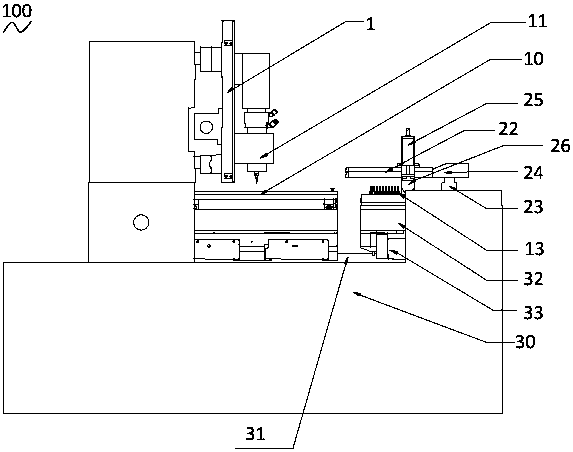

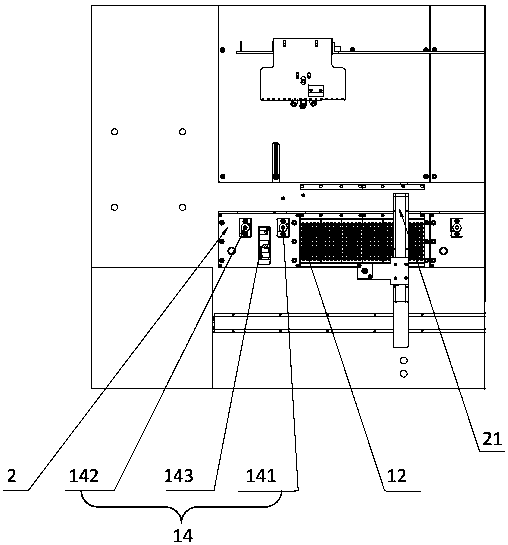

[0029] Such as figure 2 and image 3 As shown, the drilling machine 100 of the present invention is a high-efficiency PCB drilling machine for drilling the workbench 10 . The tool change mode of PCB drilling machine is mainly divided into two types: one is the upper tool change mode represented by European equipment, and the other is the lower tool change mode represented by Japanese and Taiwan equipment. The steps and methods of these two tool change modes are basically the same, and the following part of the manual will take the following tool change mode as an example to describe in detail.

[0030] The drilling machine 100 includes a drilling system 1 and a tool changing system 2 that can act independently at the same time. The drilling sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com