Steel loop control method for low-temperature wide material finishing mill frame of hot continuous rolling mill

A control method and looper technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of enterprise economic loss, looper oscillation, scrap steel between stands, etc., to reduce abnormal downtime, ensure Automatic control, solve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

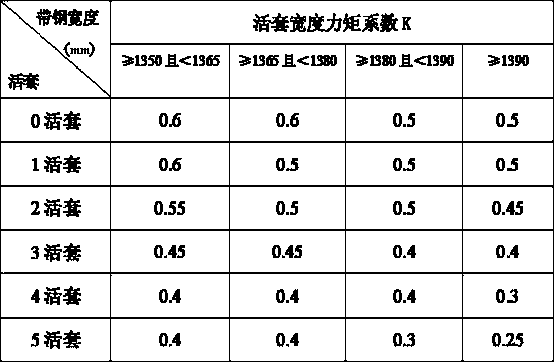

Embodiment 1

[0023] When the rolled steel grade is T510 and the width is 1350mm, the first-level computer (PLC controller) checks the width moment coefficients of all loopers through the table model. The first-level computer takes the final rolling temperature of the strip steel at 850°C and the finished strip steel width of 1350mm as the selection symbol of the control technology, and at the same time puts into the control of the corresponding rolling mill looper according to the tracking load signal of each rolling mill. The scanning time of this program is 5ms, and the value of the width torque coefficient is 0# looper: width torque coefficient 0.6; 1# looper: width torque coefficient 0.6; 2# looper: width torque coefficient 0.55; 3# looper: width Moment coefficient 0.45; 4# looper: width moment coefficient 0.4; 5# looper: width moment coefficient 0.4.

Embodiment 2

[0025] When the rolling steel grade is container plate SPAH and the width is 1380mm, the first-level computer (PLC controller) checks the width moment coefficients of all loopers through the table model. The first-level computer takes the final rolling temperature of the strip steel at 830°C and the finished strip steel width of 1380mm as the selection symbol of the control technology, and at the same time puts into the control of the corresponding rolling mill looper according to the tracking load signal of each rolling mill. The scanning time of this program is 5ms, and the value of the width torque coefficient is 0# looper: the width torque coefficient is 0.5; 1# looper: the width torque coefficient is 0.5; 2# looper: the width torque coefficient is 0.5; 3# looper: the width Moment coefficient 0.4; 4# looper: width moment coefficient 0.4; 5# looper: width moment coefficient 0.3.

[0026] If there is no selection flag, it is controlled according to the normal looper control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com