Feed screening device for livestock production

A feed sieve and frame device technology, which is applied in the direction of separating solids from solids with airflow, solid separation, chemical instruments and methods, etc., can solve problems affecting feed quality, impurity and debris cannot be screened out, etc. Achieve the effects of simple structure, convenient pouring and high stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

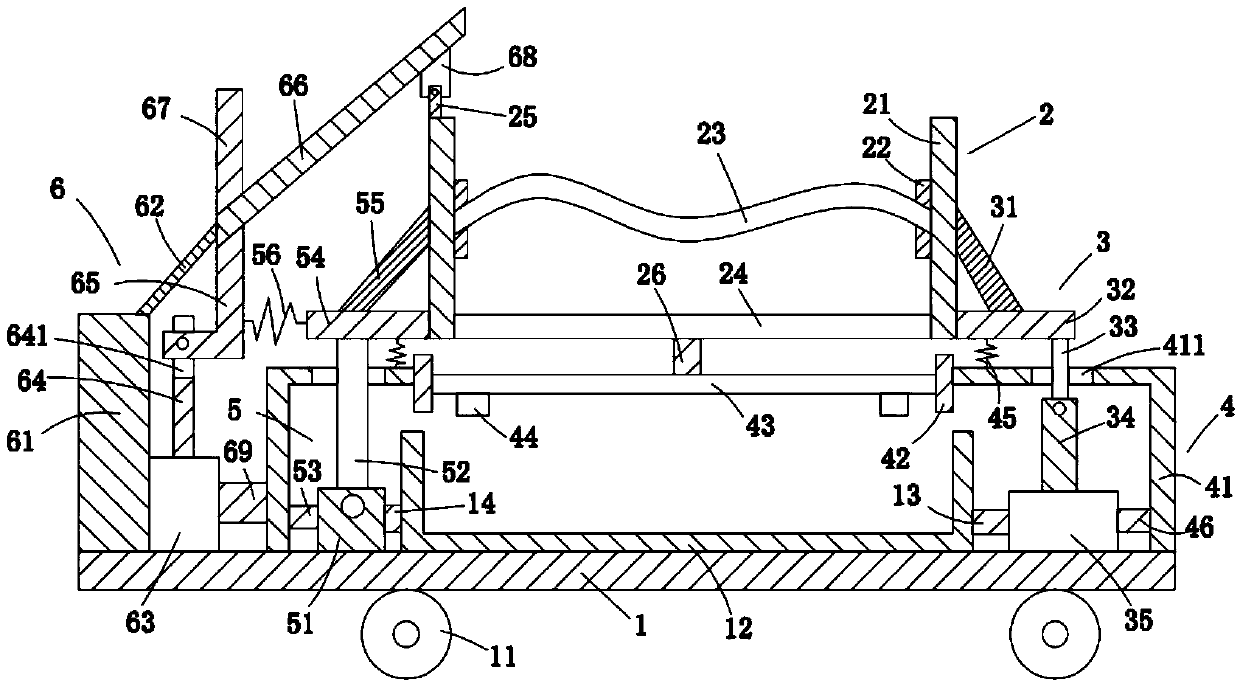

[0019] Such as figure 1 As shown, the feed screening device for animal husbandry production of the present invention includes a base plate 1, a frame device 2 positioned above the base plate 1, a cylinder device 3 positioned on the right side of the frame device 2, and a bracket positioned above the base plate 1 The device 4 , the supporting device 5 located on the left side of the frame device 2 and the unloading device 6 located on the left side of the supporting device 5 .

[0020] Such as figure 1 As shown, the base plate 1 is a cuboid, and the base plate 1 is placed horizontally. The base plate 1 is provided with a first roller 11 located below, a receiving box 12 located above the base plate 1, and a receiving box located at the bottom of the base plate 1. 12, the first crossbar 13 on the right side, and the second crossbar 14 on the left side of the receiving box 12. There are two first rollers 11 located on the left and right sides respectively, the first rollers 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com