Electromagnetic shielding structure for quick pressed cables

An electromagnetic shielding structure, press-fit technology, applied in the direction of circuits, electrical components, coupling devices, etc., can solve the time-consuming and labor-intensive production of metal shielding layer shielding wires, high requirements for connector shielding performance, and poor cable maintainability and other problems, to achieve the effect of flexible and diverse fixing methods, saving production time, and reducing stripping requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

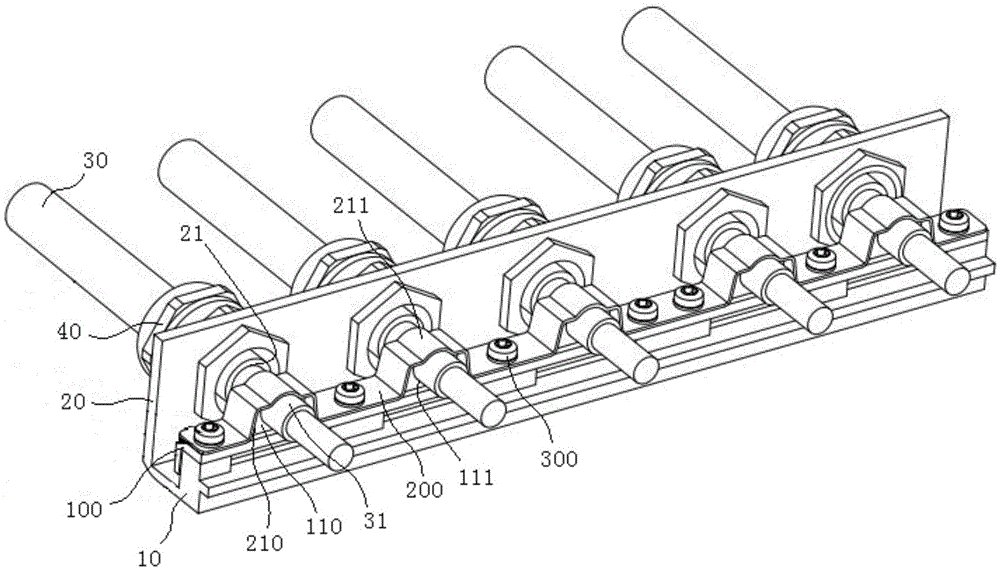

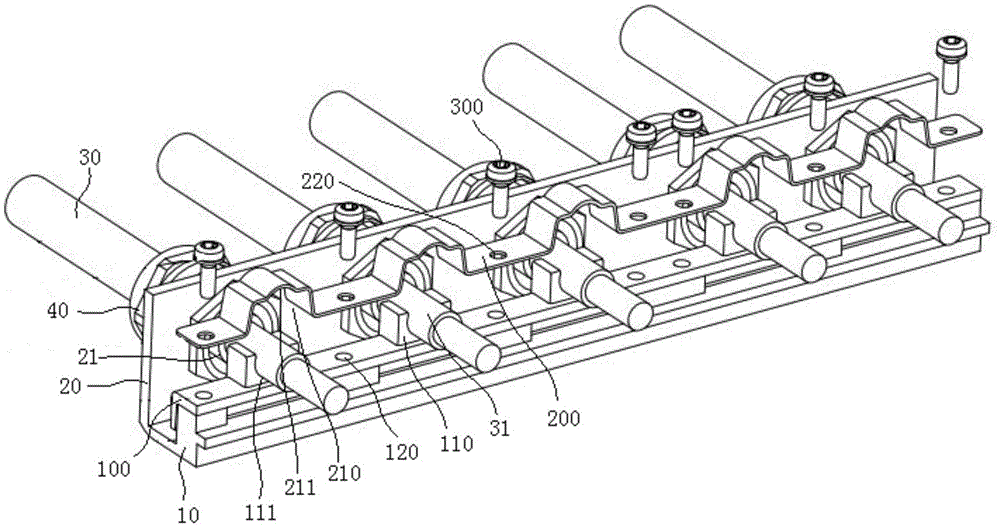

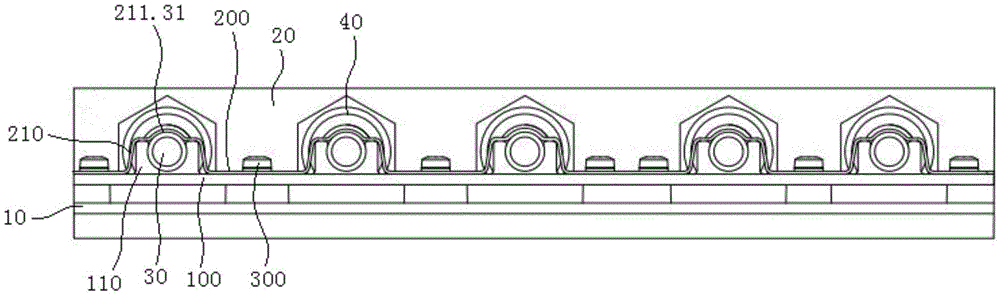

[0019] see Figure 1 to Figure 4 , shown in the figure is a quick press-fit electromagnetic shielding structure for cables, including a lower pressing plate 100 and an upper pressing plate 200 .

[0020] The lower pressing plate 100 is fixedly arranged on the shell mounting seat 10 of the motor controller, and five wiring seats 110 are arranged at intervals along the length direction on the lower pressing plate 100, and the incoming lines of the five wiring seats 110 and the housing 20 of the motor controller The holes 21 are in a one-to-one correspondence. Of course, the number of wire sockets 110 is not limited to the number in this embodiment, and it should be determined according to the number of wire inlet holes in the casing of the specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com