Vanadium-cell assembling machine

An assembly machine, vanadium battery technology, applied in the direction of fuel cell grouping, etc., can solve problems such as incapacity and precise displacement control, achieve the effect of uniform downforce and improve the overall use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

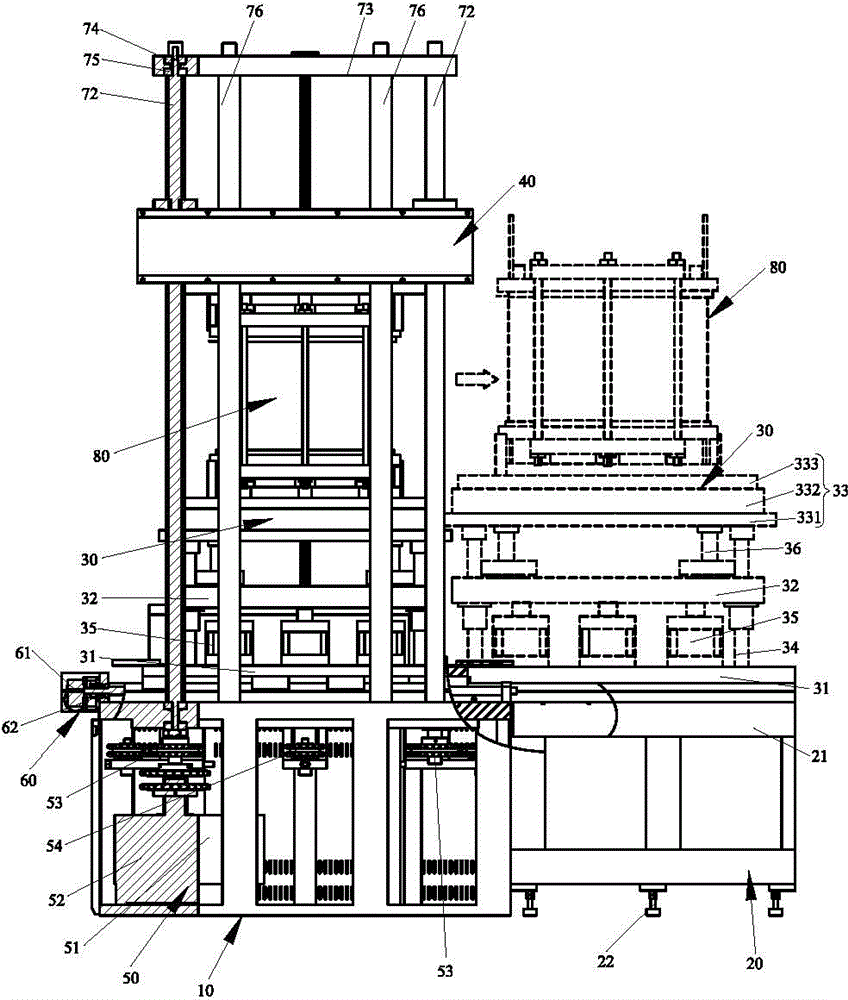

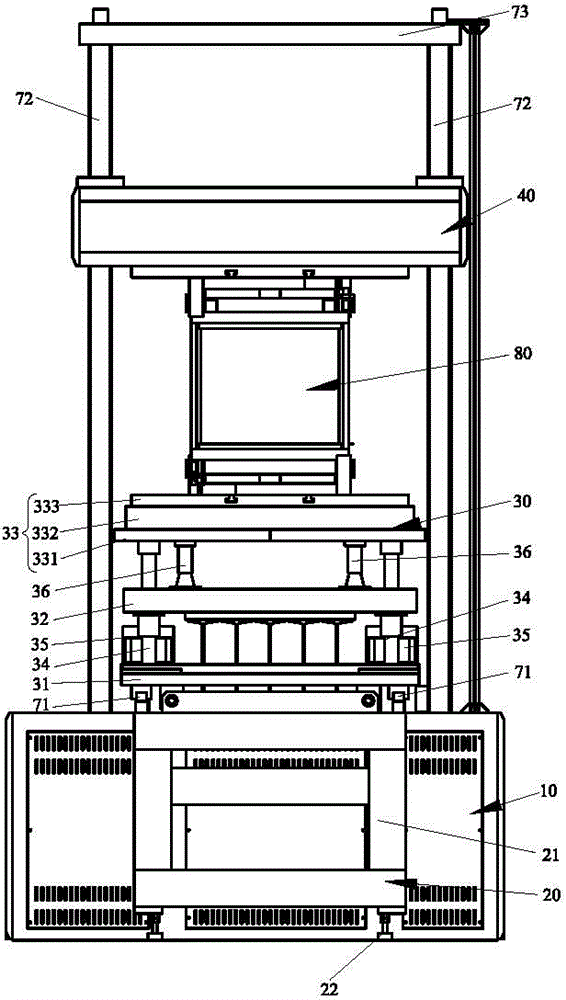

[0044] Please refer to Figure 1 to Figure 3 As shown, it shows the specific structure of the preferred embodiment of the present invention, including the assembly chassis 10, the output chassis 20, the translation assembly 30, the pressing assembly 40, the first driving device 50 and the second driving device 60 .

[0045] The output chassis 20 is spliced with the assembly chassis 10, and slide rails 71 are arranged on the planes of the output chassis 20 and the assembly chassis 10. An anchor 22, four screw rods 72 are arranged on the assembly base frame 10, the four screw rods 72 are vertically arranged and evenly distributed on the surface periphery of the assembly base frame 10, the tops of the four screw rods 72 are installed on On a fixed platform 73, the fixed platform 73 and four screw mandrels 72 are surrounded to form an assembly space. In this embodiment, the upper end of each screw mandrel 72 is rotatably installed through a plane bearing 74 and a deep groove ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com