Reciprocating rotation excitation stand system

A bench system and excitation system technology, applied in the field of testing of rotary actuators and their vibration control systems, can solve problems such as single test results, impossibility of testing, poor applicability, etc., to ensure stable operation, prevent excessive vibration, The effect of large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

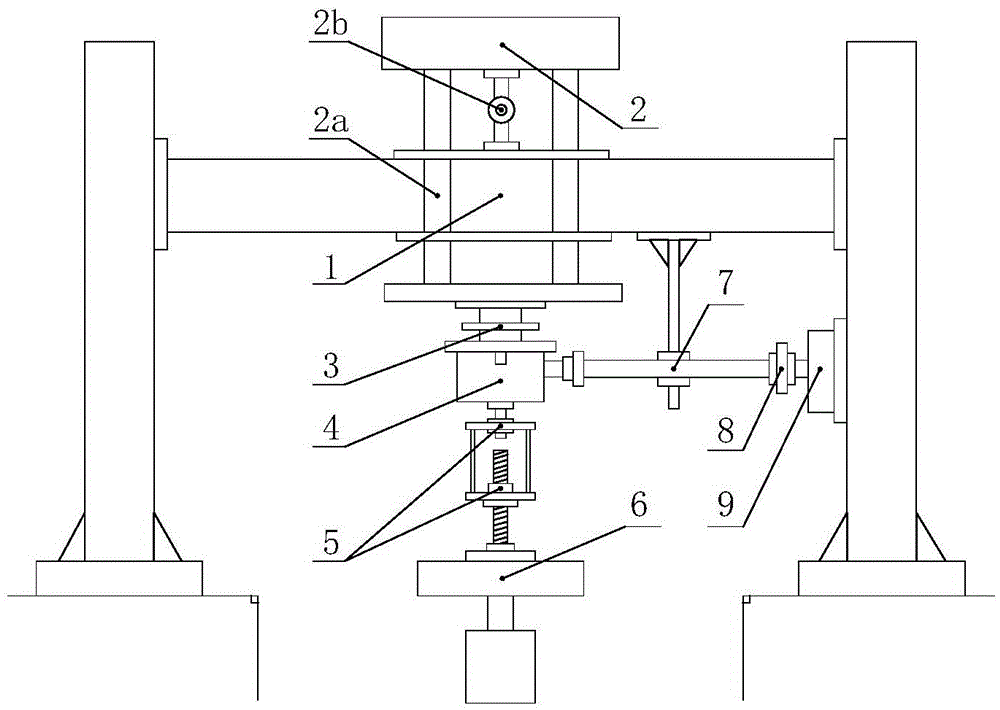

[0053] Embodiment 1: The structure of the reciprocating rotary excitation bench system in this embodiment is set as follows:

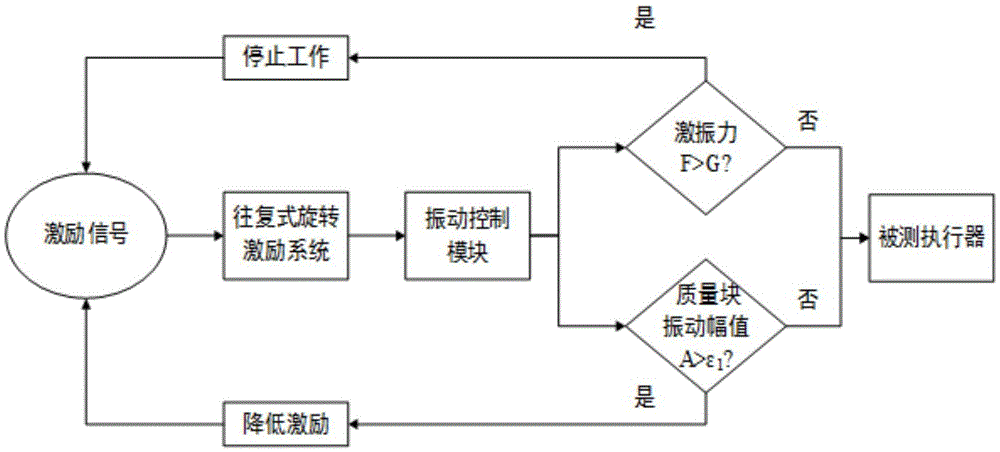

[0054] The gantry 1 is composed of columns on both sides and the top horizontal beam connected between the columns on both sides; the mass block guide platform 2 is arranged on the horizontal beam, and the mass block guide platform 2 is supported by the horizontal beam, and can move along the vertical guide column 2a lifting, a limit rod 2b is set between the top table of the mass guide table 2 and the horizontal beam, the bottom table of the quality block guide table 2 is located below the horizontal beam; The vibration control module 3, the bottom surface of the vibration control module 3 is rigidly connected with the direction changing torsion increasing device 4.

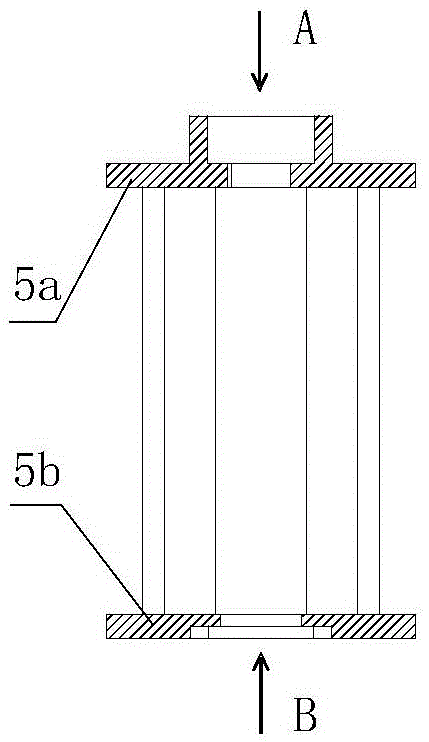

[0055] The input shaft of the direction-changing torsion-increasing device 4 is vertically downward, and is connected with the motion conversion device 5 located at the bottom of the dir...

Embodiment 2

[0075] Embodiment 2: The structure of the reciprocating rotary excitation bench system in this embodiment is set as follows:

[0076] see Figure 5 , the gantry 1 is composed of columns on both sides and the top horizontal beam connected between the columns on both sides; the mass guide platform 2 is arranged on the horizontal beam, and the mass guide platform 2 is supported by the horizontal beam, and can be guided vertically The column 2a is free to lift, and the bottom surface of the mass guide platform 2 is located below the horizontal beam; the vibration control module 3 is set on the bottom surface of the bottom surface of the mass guide platform 2, and the bottom surface of the vibration control module 3 is executed with a limited rotation angle of large torque. The housing of the device 9 is rigidly connected.

[0077] The rotating shaft of the high-torque limited-angle actuator 9 is vertically downward, and is connected with the output shaft of the reducer 10 located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com