Two-way automatic locking device in the tube

An automatic locking and locking mechanism technology, which is applied to the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of locking device detachment, locking failure, etc., achieve a firm locked state and increase the locking force , easy adjustment and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

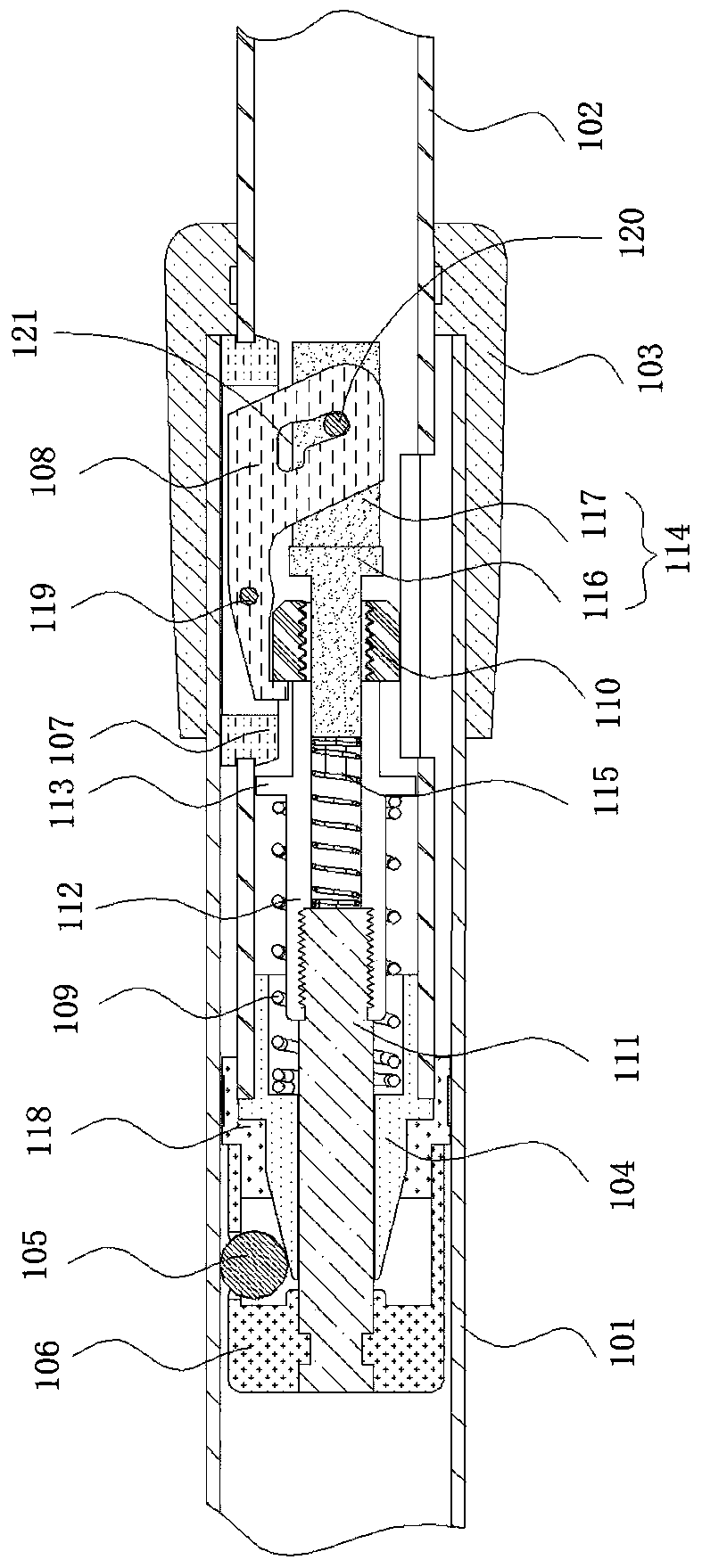

Embodiment 1

[0034] Such as figure 2 As shown, in a normal state, the bidirectional automatic locking device in the tube provided by the first embodiment is in a locked state, and the bidirectional automatic locking device in the tube includes an outer tube 101, an inner tube 102, a first locking mechanism and a second locking mechanism. Locking mechanism; the inner tube 102 is arranged inside the outer tube 101; the first locking mechanism includes a tapered sleeve 104, a slider and a friction control assembly. In this embodiment, the slider is The ball 105, the tapered sleeve 104 is arranged at the end of the inner tube 102, the friction control assembly is used to make the ball 105 move radially along the tapered surface of the tapered sleeve 104, so that the The ball 105 abuts against the inner wall of the outer tube 101 ; the second locking mechanism is used to prevent the ball 105 from breaking away from the inner wall of the outer tube 101 . In this embodiment, the number of the b...

Embodiment 2

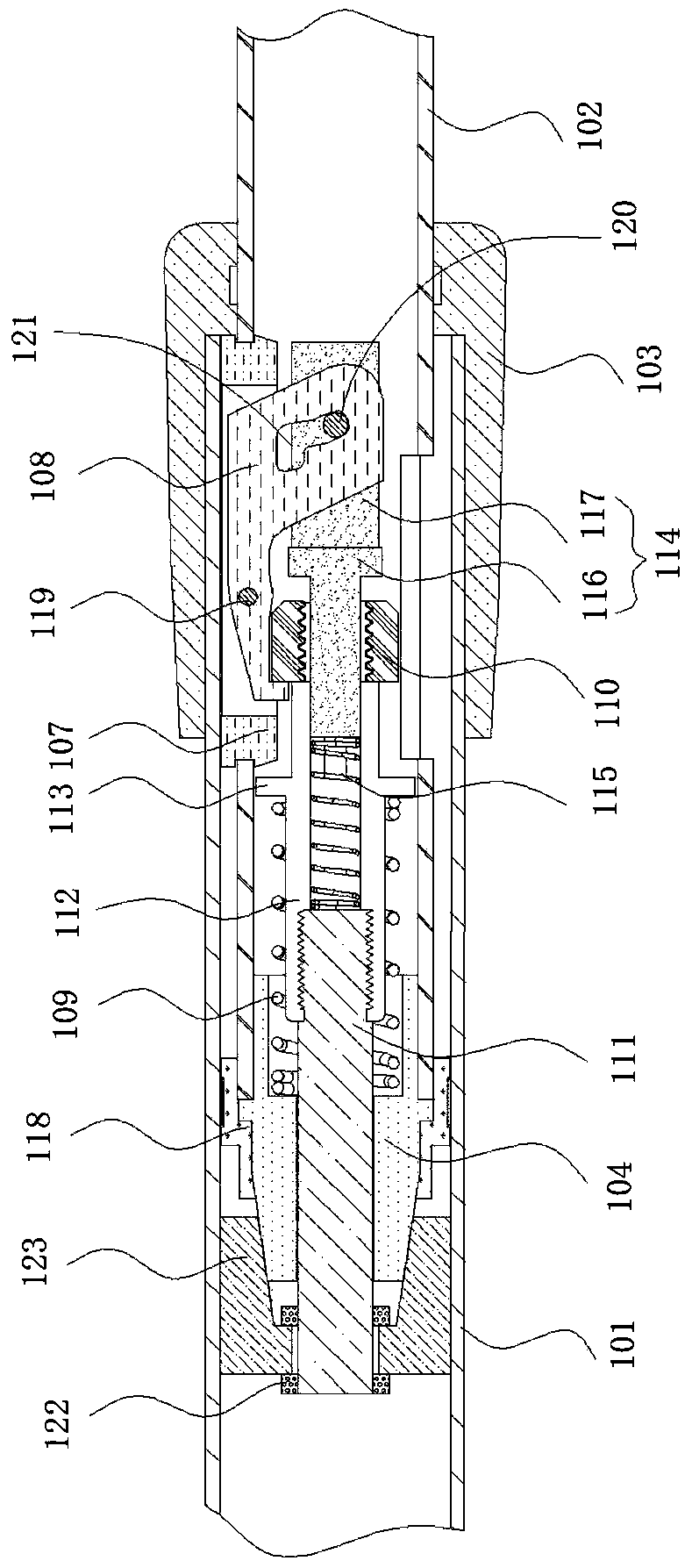

[0043] Combine below image 3 Embodiment 2 is described. The same components use the same reference numerals as in the first embodiment, and reference is made to the description of the first embodiment. The difference from Embodiment 1 is that the limiting member used in this embodiment is a bracket 122, and the sliding member used is a locking block 123. The number of the locking blocks 123 is multiple, and the locking block Block 123 is provided with a wedge-shaped surface that cooperates with the tapered surface of said tapered sleeve 104 .

[0044] The unlocking and locking movement process of the in-pipe bidirectional automatic locking device provided in this embodiment is as follows:

[0045] Unlocking process: such as image 3 As shown, a leftward external force is applied to the end of the second rod part 117, the second rod part 117 and the first rod part 116 move to the left together, the elastic member 115 is compressed, and at the same time drives The second sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com