Ventilation shaft structure with rain-proof louvers

A technology of rain-proof louvers and ventilation shafts, which is applied to building components, building structures, vertical pipes, etc., can solve the problems of ventilation resistance, rain-proof louver resistance, humidity increase, etc., and achieve the effect of convenient construction and drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

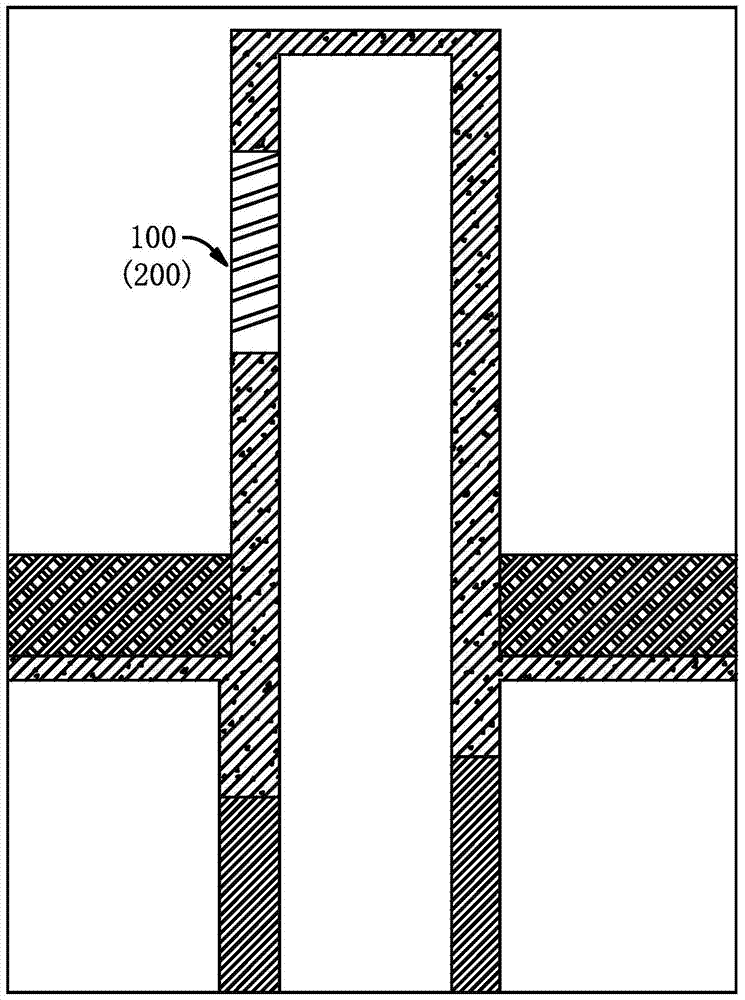

[0039] This embodiment provides a ventilation shaft structure provided with rain-proof louvers, the ventilation shaft structure includes a ventilation shaft, the lower part of the ventilation shaft is arranged below the top surface of the fan room in the basement and communicates with the fan room in the basement, and the upper part protrudes from the basement The fan room is arranged on the top surface, and the upper part of the ventilation shaft is enclosed by several side walls and a top plate, at least one of the side walls is provided with a vent opening connected to the external environment. In addition, the ventilation shaft structure also includes a protective wall enclosing the outside of each vent, the protective wall is provided with rain-proof louvers, the rain-proof louvers are opposite to the vents, and the area of the rain-proof louvers greater than the area of the corresponding vent.

Embodiment 2

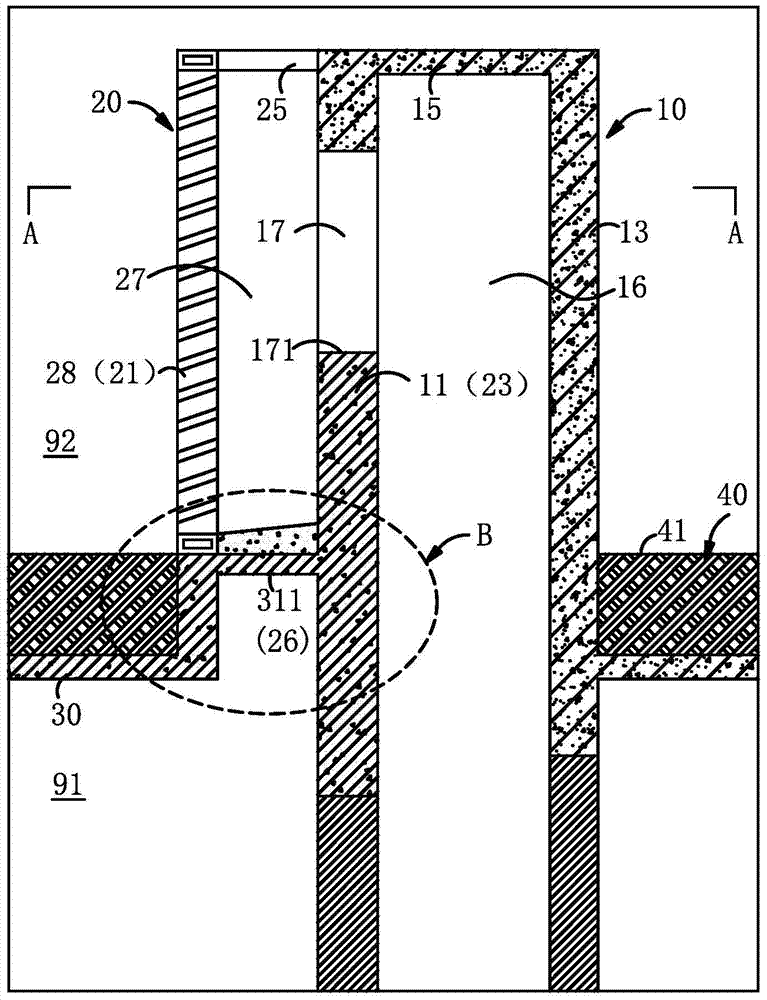

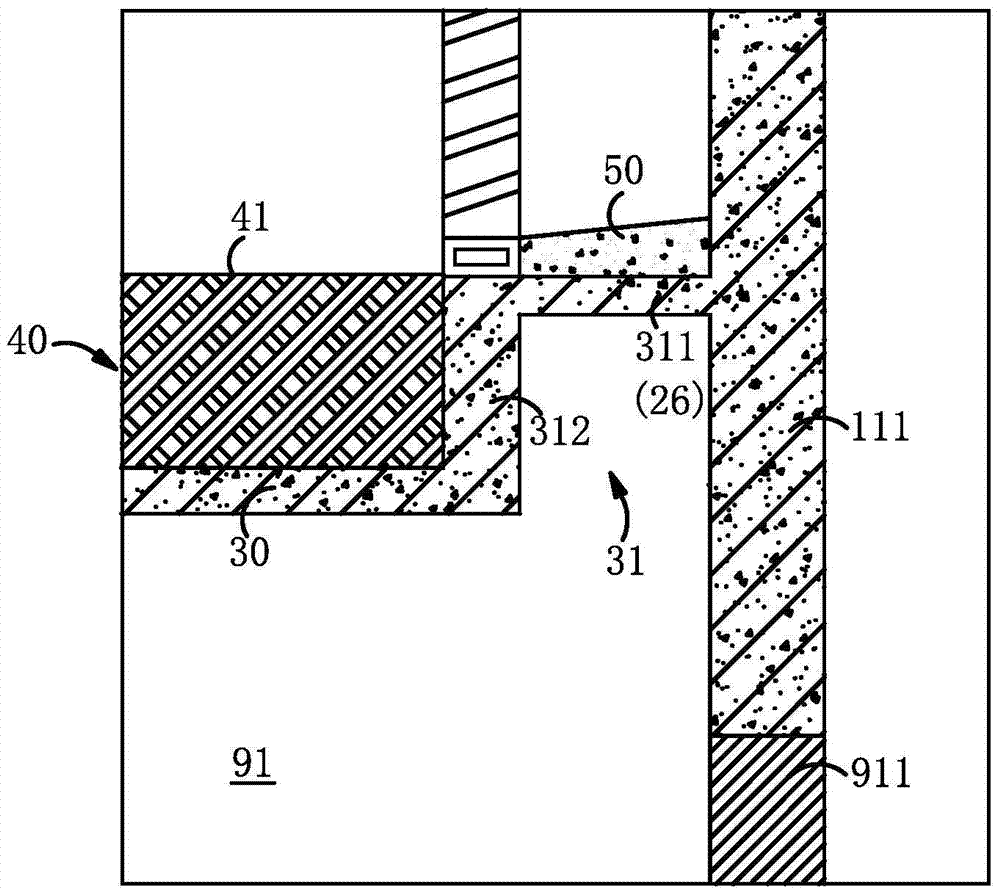

[0041] Such as figure 2As shown, the present embodiment provides a ventilation shaft structure provided with rain-proof louvers, including: a ventilation shaft 10, the upper part of which protrudes from the top surface 30 of the fan room in the basement and is set upward, and the lower part is arranged on the top surface of the fan room in the basement 30 and is communicated with this basement fan room 91. The top of this ventilation shaft 10 comprises four side walls and top plate 15, wherein, four side walls are respectively left side wall 11, upper side wall 12, right side wall 13 and lower side wall 14 (referring to Figure 4 ). The four side walls and the top plate 15 enclose a passage 16 forming the upper part of the ventilation shaft. Wherein, a ventilation opening 17 is provided on the left side wall 11, and the ventilation opening 17 communicates with the passage 16 on the upper part of the ventilation shaft and the external space 92;

[0042] The protective wall ...

Embodiment 3

[0050] Such as figure 2 As shown, the present embodiment provides a ventilation shaft structure provided with rainproof louvers, including:

[0051] Ventilation shaft 10, the upper part of the ventilation shaft protrudes from the top surface 30 of the fan room in the basement and is set upwards, and the lower part is located below the top surface 30 of the fan room in the basement and communicates with the fan room 91 in the basement. The top of this ventilation shaft 10 comprises four side walls and top plate 15, wherein, four side walls are respectively left side wall 11, upper side wall 12, right side wall 13 and lower side wall 14 (referring to Figure 4 ). The four side walls and the top plate 15 enclose a passage 16 forming the upper part of the ventilation shaft. Wherein, a ventilation opening 17 is provided on the left side wall 11, and the ventilation opening 17 communicates with the passage 161 on the upper part of the ventilation shaft and the external space 92; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com