Reinforced mud-filled pipe bag

A mud-filled pipe bag and reinforcement technology, which is applied in the field of silt-promoting enclosure engineering, can solve problems such as the impact of tides on operation time, high personnel safety risks, and difficult control of underwater construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

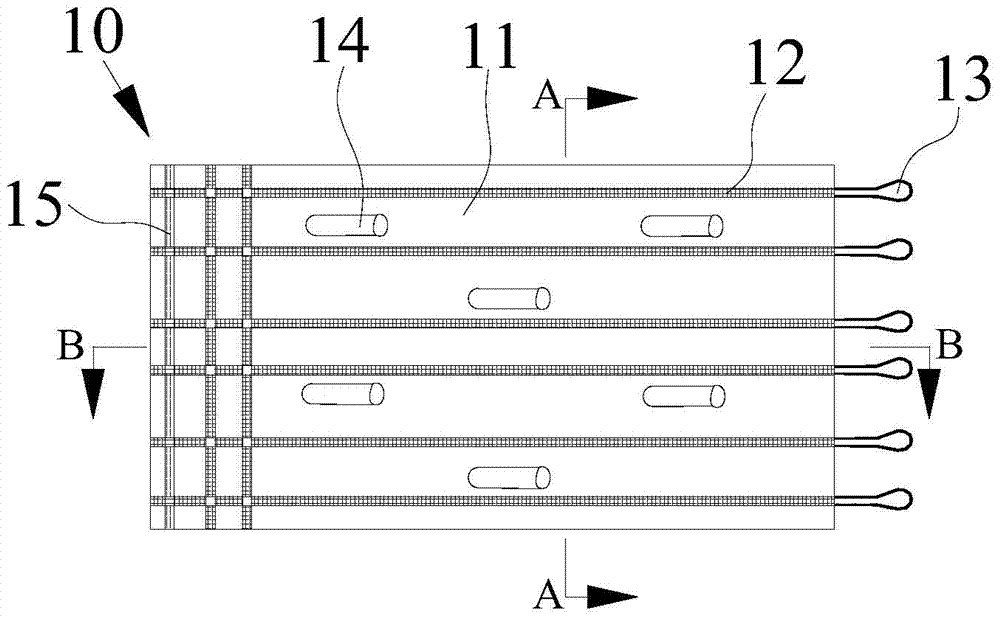

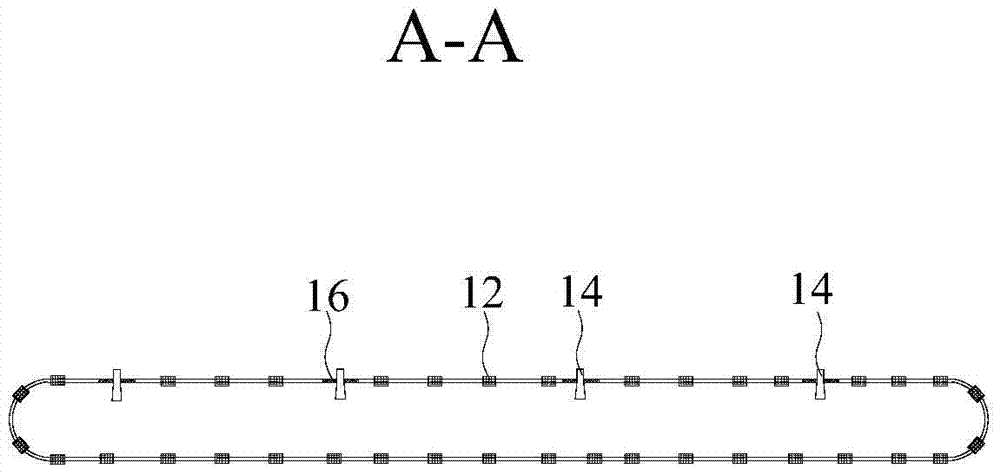

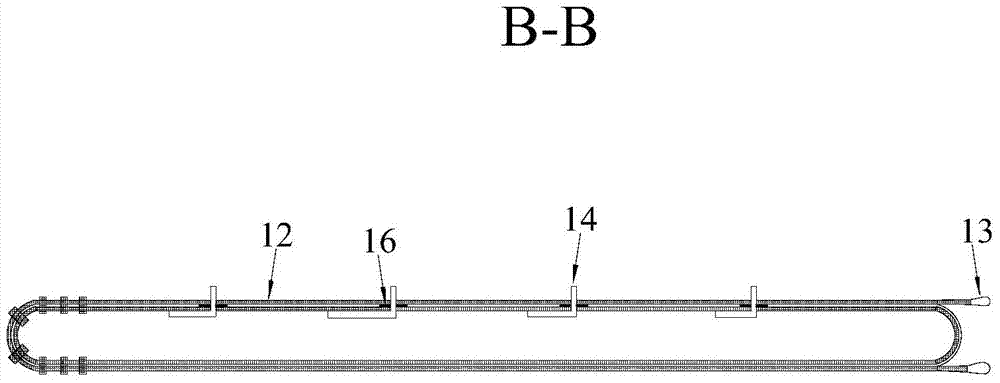

[0016] Reinforced mud-filled tube bag 10, comprising bag body 11, described bag body 11 is cylindrical, and bag body 11 is long 120m, and width is 25m, and bag body 11 is made the length and reserves certain surplus degree, and every 5m on bag body 11 uses The paint is used to mark the footage, and the number of layers used and the location of the bag body 11 are marked. The bag body 11 adopts double layers of 150g / m 2 It is made of plastic woven cloth. The seams of the bag body 11 are in the form of double-thread sewing. The seam direction is parallel to the laying direction. Seams are strictly prohibited in the direction of tension; the outer side of the bag body 11 is uniformly sewn with reinforcement tape 12. The reinforced belt 12 connects the double-layer bag cloth as a whole, the width of the reinforced belt 12 is 6cm, the distance is 1m, the tensile strength of the reinforced belt 12 is 20000N, and the elongation is 17%; There are several pulp inlets, the diameter of t...

Embodiment 2

[0020] The reinforced mud-filled pipe bag 10 includes a bag body 11. The bag body 11 is cylindrical. The bag body 11 is 162m long and 36m wide. A certain margin is reserved for the length of the bag body 11. Every 8m on the bag body 11 is used The paint marks the footage, and marks the number of layers and locations used for the bag body 11. The bag body 11 is sewn with double-layer polypropylene filament woven fabric. The seam direction is parallel to the laying direction, and seams are strictly prohibited in the direction of tension; the outer side of the bag body 11 is evenly sewn with a reinforcement belt 12, which connects the double-layer bag cloth as a whole, and the width of the reinforcement belt 12 is 10cm , the spacing is 2m, the tensile strength of the reinforced belt 12 is 18000N, and the elongation is 20%; there are several pulp inlets on the bag body 11, the diameter of the pulp inlet is 15cm, and the pulp inlets are distributed in a "plum blossom" shape. The ar...

Embodiment 3

[0023] The reinforced mud-filled pipe bag 10 includes a bag body 11. The bag body 11 is cylindrical. The bag body 11 is 126m long and 35m wide. A certain margin is reserved for the length of the bag body 11. Every 7m on the bag body 11 is used The paint is used to mark the footage, and the number of layers used and the location of the bag body 11 are marked. The bag body 11 adopts double layers of 230g / m 2Made of plastic woven cloth, the seams of the bag body 11 are in the form of double seams, and are sewn with double threads. The seam direction is parallel to the laying direction, and seams are strictly prohibited in the direction of tension; the outer side of the bag body 11 is uniformly sewn with reinforcement 12. The reinforced belt 12 connects the double-layer bag cloth as a whole, the width of the reinforced belt 12 is 8cm, the distance is 1m, the tensile strength of the reinforced belt 12 is 23000N, and the elongation is 16%; There are several pulp inlets, the diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com