Pneumatic gripper type automatic roller cover opening mechanism

An automatic lid opening and air gripper technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of wasting human resources, reducing production efficiency, and many human operation errors, so as to improve production efficiency, save human resources, and reduce manual operations. effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

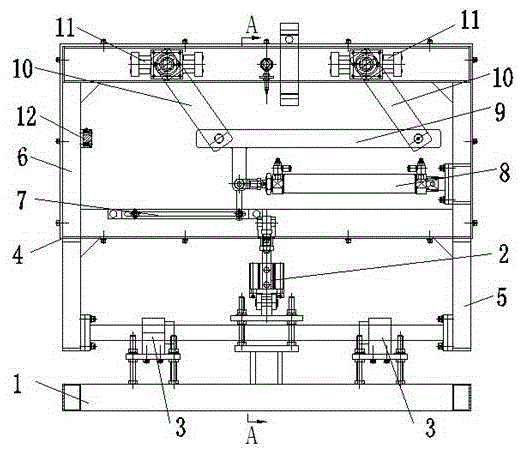

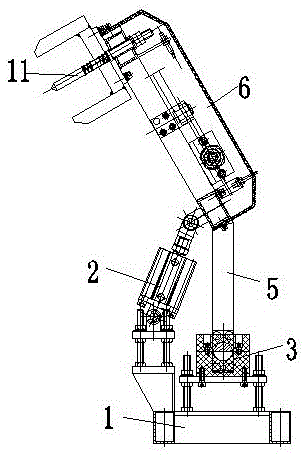

[0011] Combine below figure 1 with figure 2 Specific description embodiment:

[0012] Such as figure 1 with figure 2 As shown, the air claw type drum automatic cover opening mechanism includes a base 1, and the base 1 is provided with a frame cylinder 2 and a rotating joint 3, and the rotating joint 3 is hingedly connected with a frame 4, and the frame 4 includes Connecting frame 5 and station frame 6, described connecting frame 5 links to each other with revolving joint 3, the output end of frame cylinder 2 is connected at the bottom of station frame 6, through the drive of frame cylinder 2 and the cooperation of revolving joint 3 To realize the overturning of the frame 4 in place, a chute 7 is provided at the lower part of the station frame 6; an air claw cylinder 8 is arranged at the middle part of the station frame 6, and the output end of the air claw cylinder 8 is connected with a total connecting rod 9, One end of the total connecting rod 9 is arranged in the chut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com