a winding device

A winding device and bobbin technology, applied in the direction of transportation and packaging, thin material handling, and delivery of filamentous materials, etc., can solve the problems of low automation and high equipment cost, and achieve cost saving, enhanced reliability, and simple The effect of logical actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

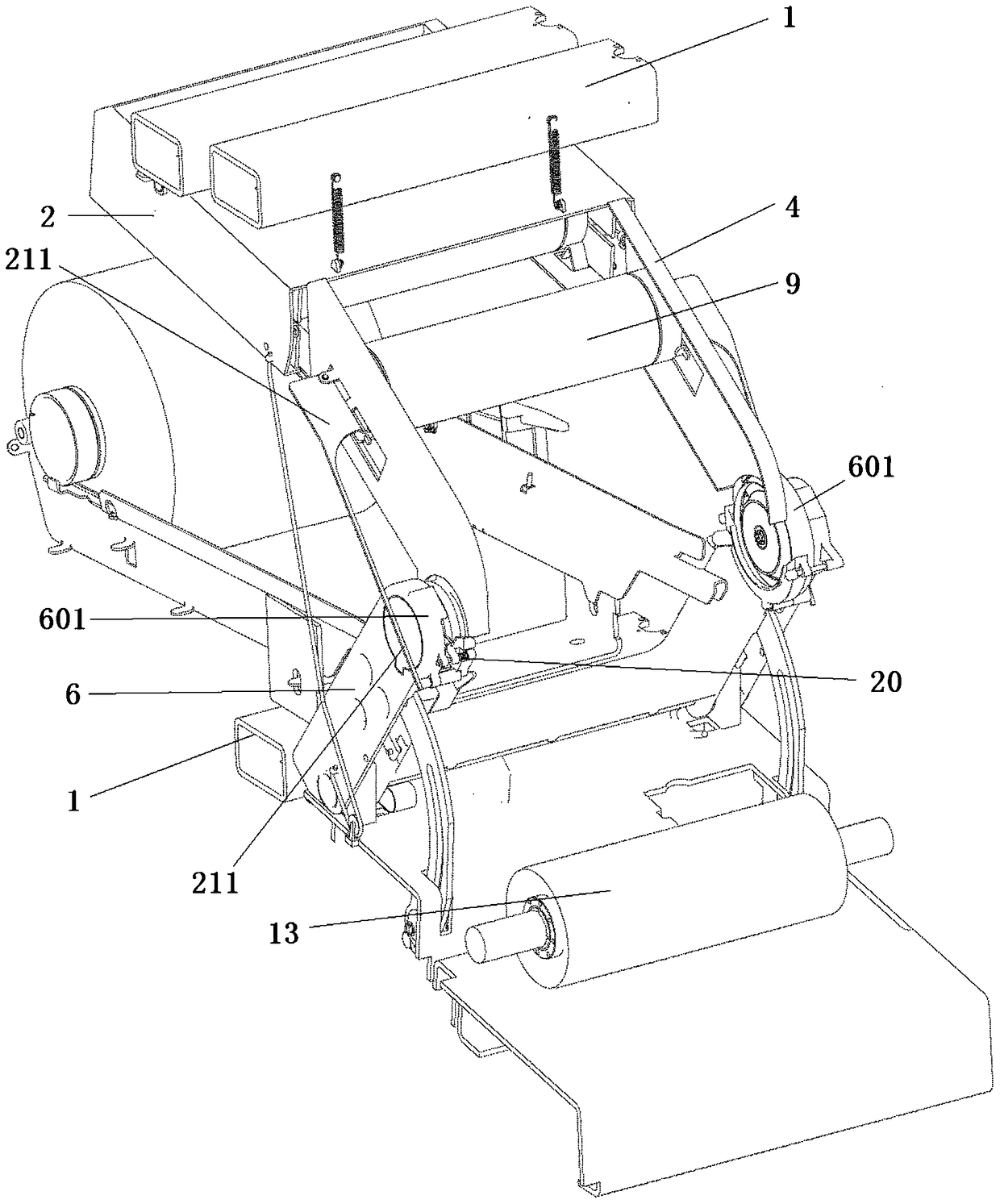

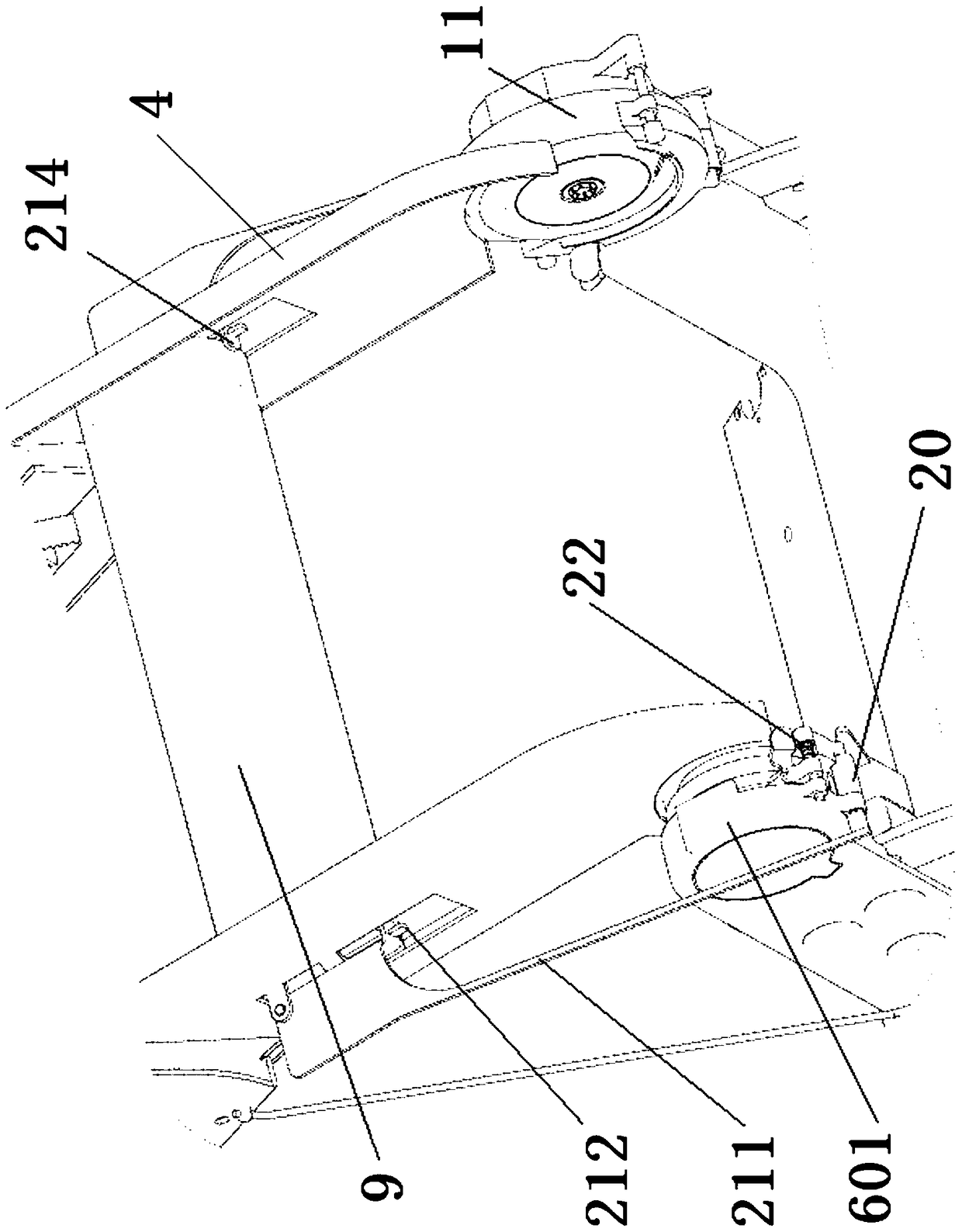

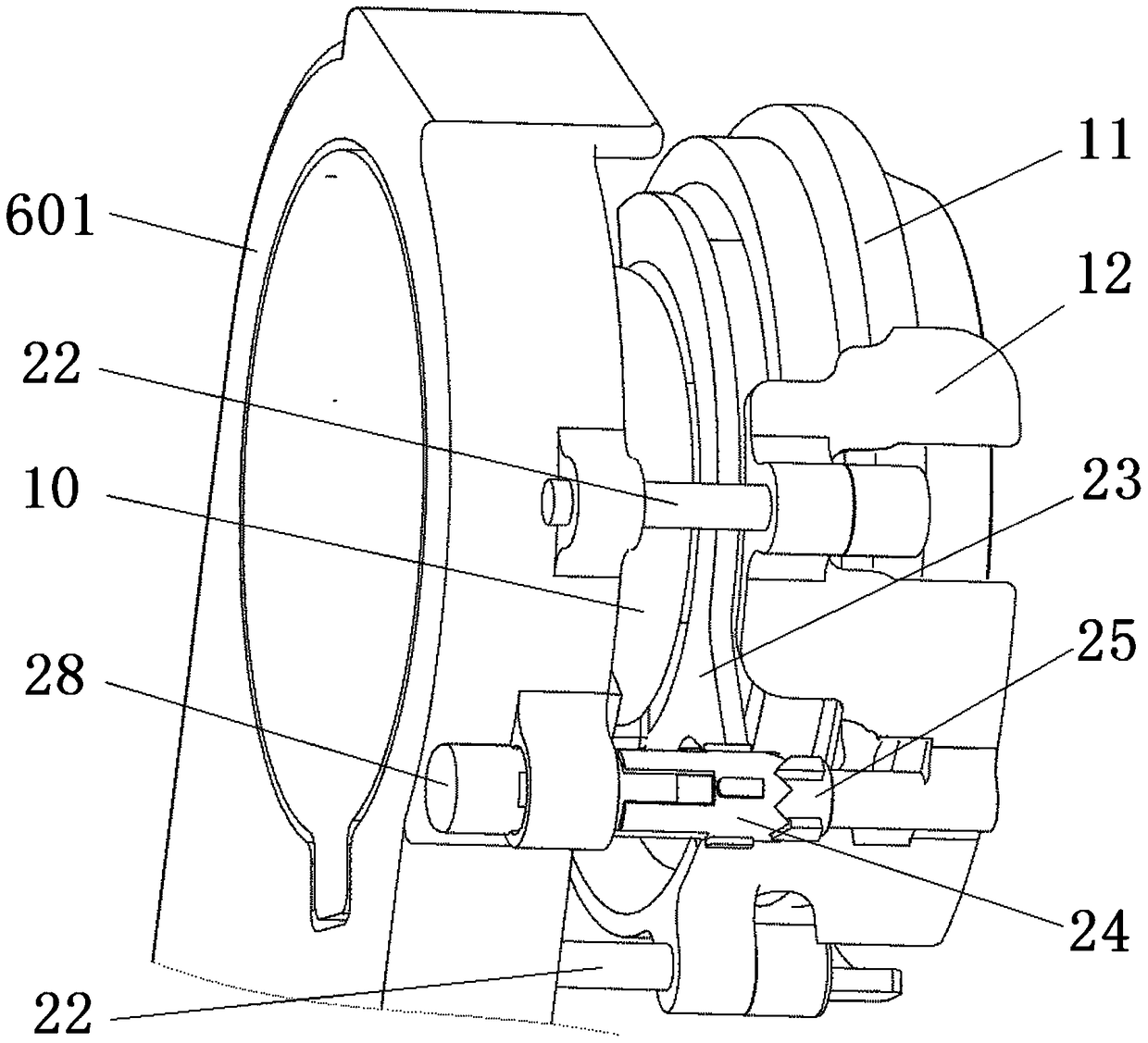

[0035] The winding device of the present invention will be further described in detail below in conjunction with the accompanying drawings. A winding device, comprising a bobbin conveying track 4 and a rotatable bobbin holder 6, the bobbin holder 6 can clamp the bobbin 9, and the clamping end 601 of the bobbin holder is provided with a clamp for clamping the bobbin 9 disc 11, the chuck 11 can be extended and retracted, and the winding device also includes a control mechanism that can make the bobbin delivery track 4 automatically supply bobbins to the bobbin rack 6 when the chuck 11 is in a set state, such as figure 1 and figure 2 shown.

[0036] During the winding process, the diameter of the bobbin held by the bobbin holder 6 will continue to increase. When a winding is completed, the bobbin 9 full of silk will break away from the chuck 11 of the bobbin holder, and then to the chuck A new bobbin 9 will be reinstalled on the disk 11 to repeat the above-mentioned winding pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com