Modular profile shelf

A modularization and profile technology, applied in the direction of transportation, packaging, storage devices, etc., can solve the problems of not being able to pick out profiles quickly, cannot be transferred out of profiles, hidden safety hazards, etc., to solve the confusion of the other party, stabilize the connection, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be described in detail below with reference to the drawings and specific embodiments.

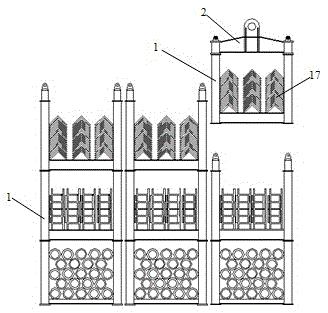

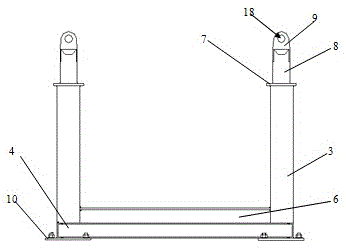

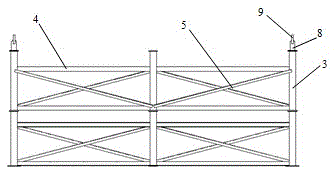

[0021] Such as Figure 1 to Figure 7 As shown, the modular profile shelf of the present invention includes a shelf 1 and a hanger 2; wherein each shelf is stacked, the top of the shelf is fixed to the bottom of the corresponding shelf above it, and the bottommost shelf is fixed to the ground The storage rack includes the column 3 that constitutes the main support structure, the connecting strip 4 that is positioned at both sides of the storage rack and connects each column horizontally, and the resistance bar 5 that is obliquely cross-connected to the adjacent column, and the corresponding column is provided with a storage beam at the bottom of the storage rack. 6. The profile 17 is placed on the storage beam; the storage rack and the hanger are flexibly connected and fixed.

[0022] The column is a hollow structure, the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com