An Intelligent Compensation and Anti-vibration Turning Tool and Its Control System

A vibration avoidance and turning tool technology, applied in the field of cutting processing, can solve the problems of scrapped processing tools, loud noise, and reduce the surface quality of the processed workpiece, so as to avoid turning chatter, improve turning accuracy, and use flexible and changeable effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

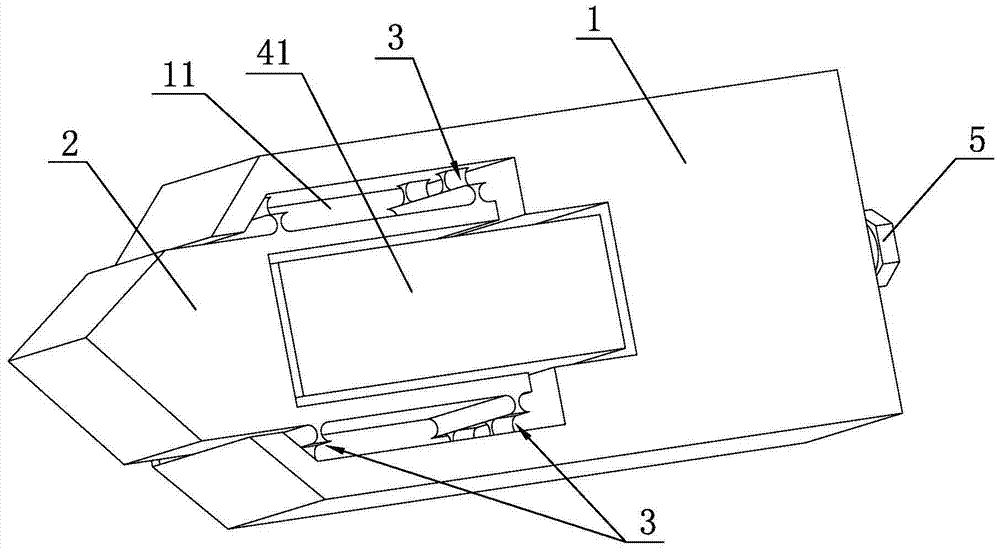

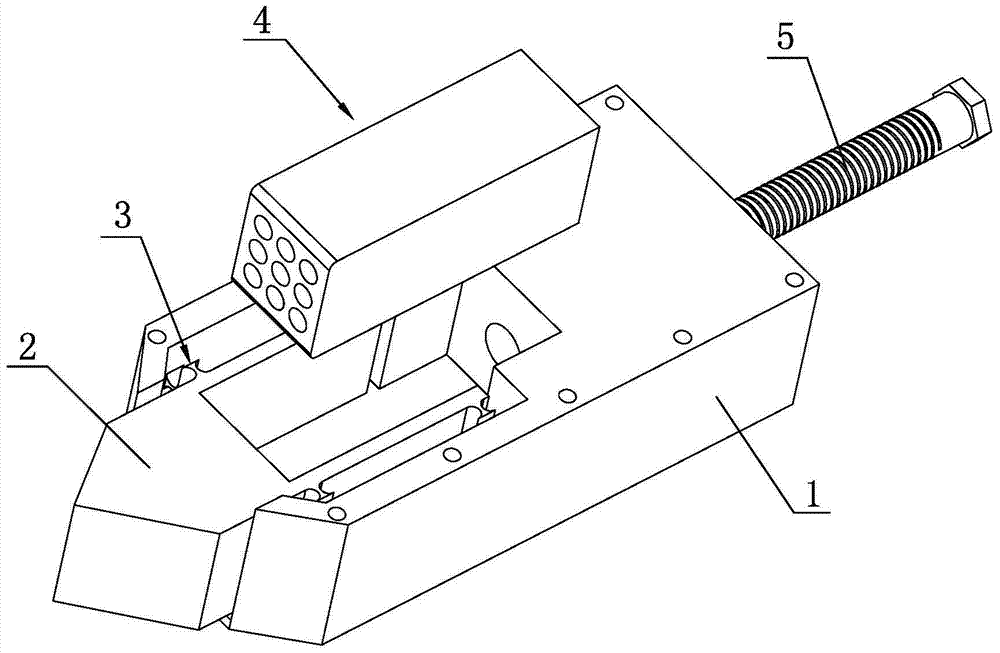

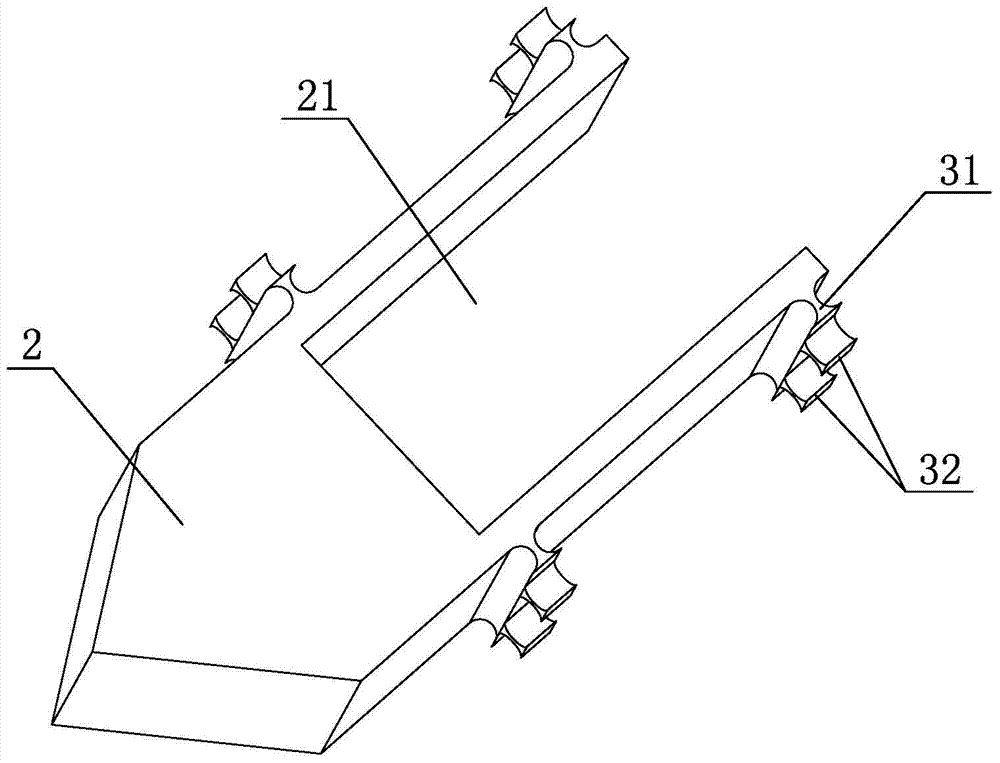

[0019] Embodiment 1: As shown in the figure, an intelligently compensated vibration-absorbing turning tool includes a cutter body 1 and a cutter head 2 that are independent of each other. The cutter body 1 is provided with an inner cavity 11, and the rear end of the cutter head 2 extends horizontally into it. In the cavity 11, four sets of two-way flexible hinges 3 are fixed between the two sides of the rear end of the cutter head 2 and the cavity wall of the inner cavity 11, and the four sets of two-way flexible hinges 3 are symmetrically arranged in pairs along the axial centerline of the cutter head 2 The two-way flexible hinge 3 includes a first flexible hinge 31 that allows the cutter head 2 to be fine-tuned along the radial direction of the workpiece and a second flexible hinge 32 that allows the cutter head 2 to be fine-tuned up and down. The first flexible hinge 31 is integrally connected with the cutter head 2, The second flexible hinge 32 is vertically fixed on the fi...

Embodiment 2

[0021] Embodiment two: as shown in the figure, a kind of control system of intelligent compensation vibration-absorbing turning tool includes force sensor 6, charge amplifier 7, data acquisition card 8, computer processing system 9 and power amplifier 10, and force sensor 6 is fixedly installed on The head of the cutter head 2, the charge amplifier 7 is electrically connected with the force sensor 6 and the data acquisition card 8 respectively, the computer processing system 9 is electrically connected with the data acquisition card 8 and the power amplifier 10 respectively, and the power amplifier 10 is electrically connected with the piezoelectric ceramic driver 42 connect.

[0022] In the above-mentioned embodiment, the working principle of the position compensation of the vibration-absorbing turning tool is: when the turning tool is turning, if the turning force measured by the force sensor 6 becomes larger (that is, the turning thickness becomes larger), the charge amplifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com