PU puffed sole and production process thereof

A preparation process and popcorn technology, which is applied in the direction of shoe soles, footwear, household components, etc., can solve the problems of complex preparation process, high cost and energy consumption, achieve strong air permeability, save equipment cost, and relieve foot pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

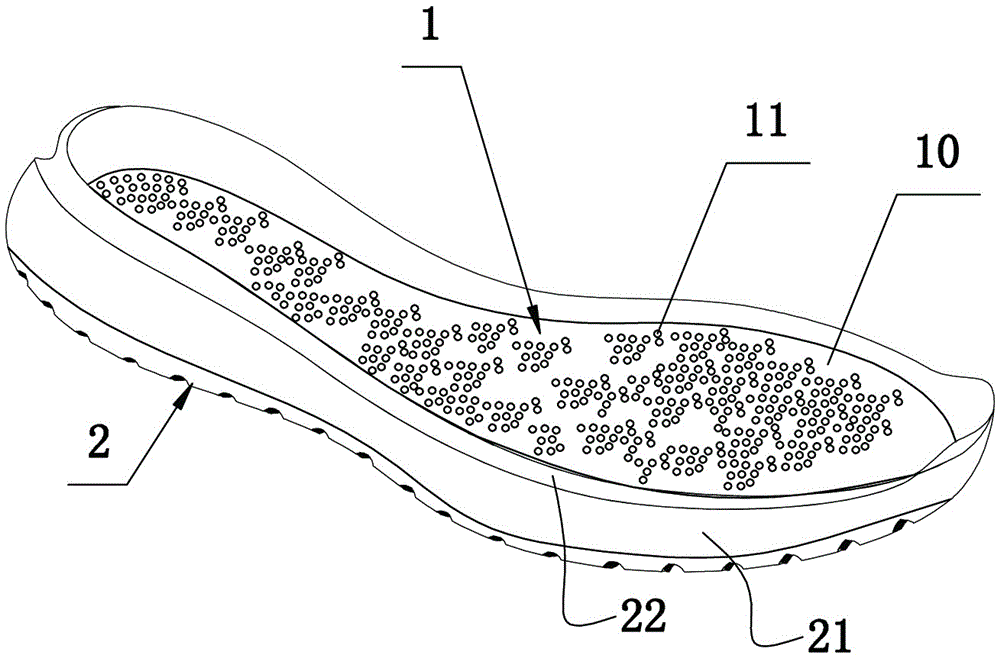

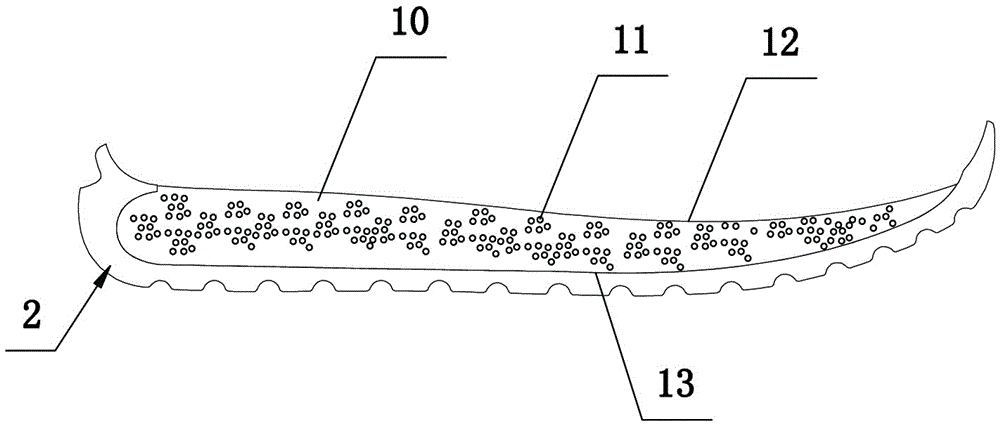

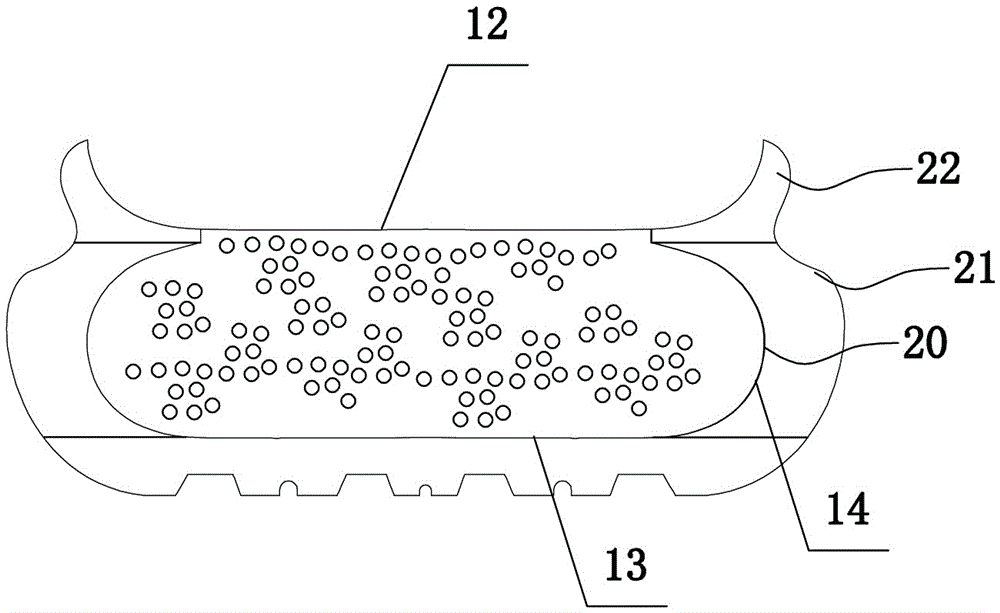

[0037] refer to figure 1 , figure 2 and image 3 . A PU popcorn sole, comprising a midsole shoe material 1 and a shoe outsole 2, the midsole shoe material 1 comprising a PU base layer 10 and a plurality of TPU popcorn foam particles evenly mixed in the PU base layer 10 11. Wherein, the TPU popcorn foamed particles 11 are spherical or ellipsoidal. The diameter of the TPU popcorn foamed particles 11 is 30 μm˜300 μm. By setting and mixing TPU popcorn particles into the existing PU raw materials, the existing PU production process is adopted, so that the prepared PU soles are evenly mixed with TPU popcorn particles, thereby effectively improving the existing PU soles. Performance improvement can effectively improve the softness of PU soles, making them lighter in weight and more breathable, making them have the advantages of both PU soles and new TPU...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| wear volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com