Toggle-lever tension lock

A technology for locking devices and closing openings, applied in the direction of clamping devices, closing, packaging, etc., can solve problems such as clamping and locking device pollution, and achieve good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

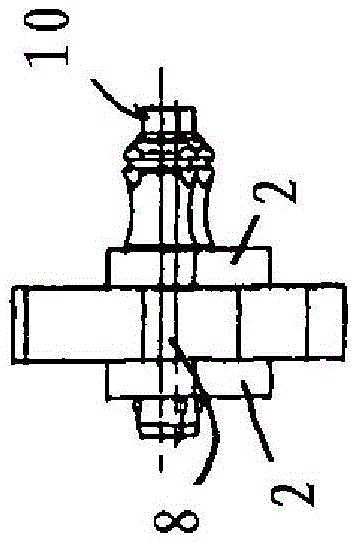

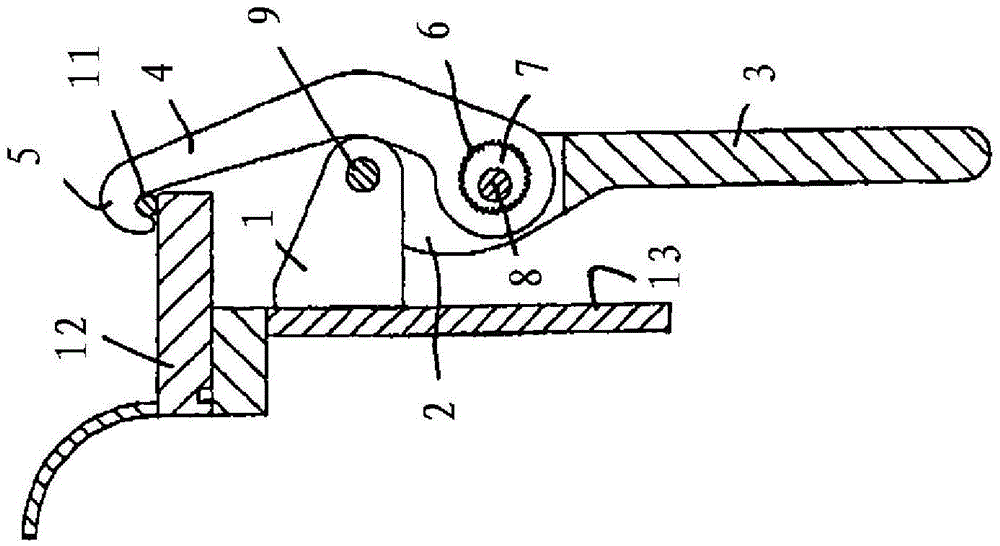

[0022] The clamping closure shown in the drawings comprises an approximately triangular base body 1 which can be fixedly or releasably arranged, for example, on a wall of a container and which forms a pivot for the clamping closure in its upper end region. Revolving bearing. The clamping lock also comprises a pivot element 2 which, in side view, has approximately the shape of an inverted triangle and has two triangular side sections and a connecting section. The two side sections of the pivot element 2 are pivotally mounted on the base body 1 , more precisely on the base body via a pivot pin or bearing pin 9 . The two side sections therefore surround the base body 1 on both sides.

[0023] The pivot element 2 is also provided with a clamping lever 3 which is arranged on the connection section of the pivot element 2 . Furthermore, the pulling bow 4 is rotatably mounted on the pivot element 2 via a transverse pin 8 . The transverse pin 8 is mounted rotatably in two side secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com