High-thermal conductivity metal substrate, fabrication method thereof, LED module and fabrication method of LED module

A heat-conducting metal plate and metal substrate technology, applied in semiconductor devices, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve the problems affecting the quality of LED modules, low bonding force, etc., to speed up the efficiency of mass industrial production , Increase adhesion and ensure the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

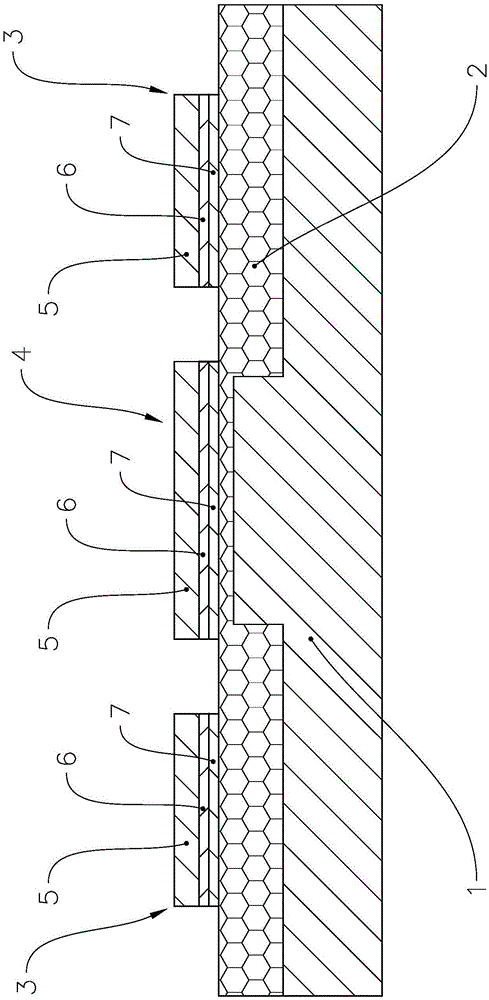

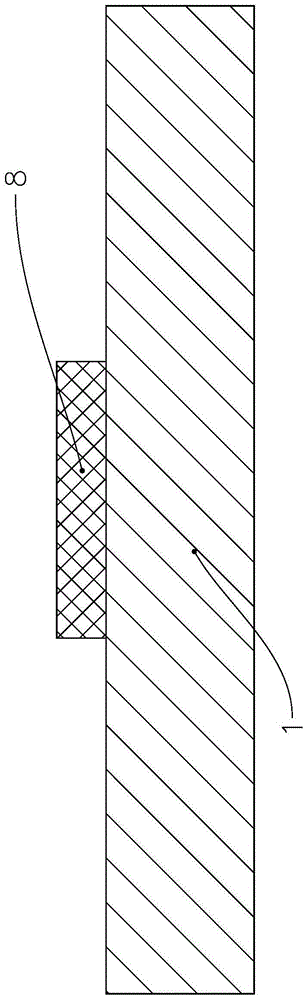

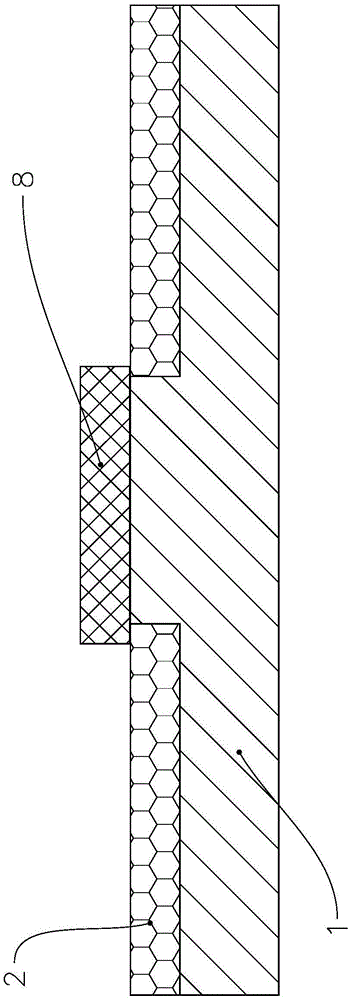

[0033] Such as figure 1As shown, the highly thermally conductive metal substrate of the present invention includes a thermally conductive metal plate 1 , preferably, the thermally conductive metal plate 1 is an aluminum substrate. A part of at least one surface of the heat-conducting metal plate 1 is oxidized to form an oxidized insulating layer 2 , and a conductive pattern layer 3 and a heat-conducting pad 4 are formed on the oxidized insulating layer 2 . The insulating oxide layer 2 on the surface covered by the heat conduction pad 4 is thinner than the insulating oxide layer 2 on the surface covered by the conductive pattern layer 3 . Preferably, the thickness of the insulating oxide layer 2 on the surface covered by the heat conduction pad 4 is 3 microns to 5 microns, and the thickness of the insulating oxide layer on the surface covered by the conductive pattern layer 3 is 35 microns to 50 microns. Wherein, the conductive pattern layer 3 and the heat conduction pad 5 bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com