Insulation cylinder and transformer

A technology for transformers and insulating cylinders, applied in the field of transformers, can solve the problems of high requirements on dimensional tolerance accuracy, difficult assembly, inconvenient installation of spacers, etc., and achieves the effects of shortening assembly time, facilitating single-person operation, and achieving significant economic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

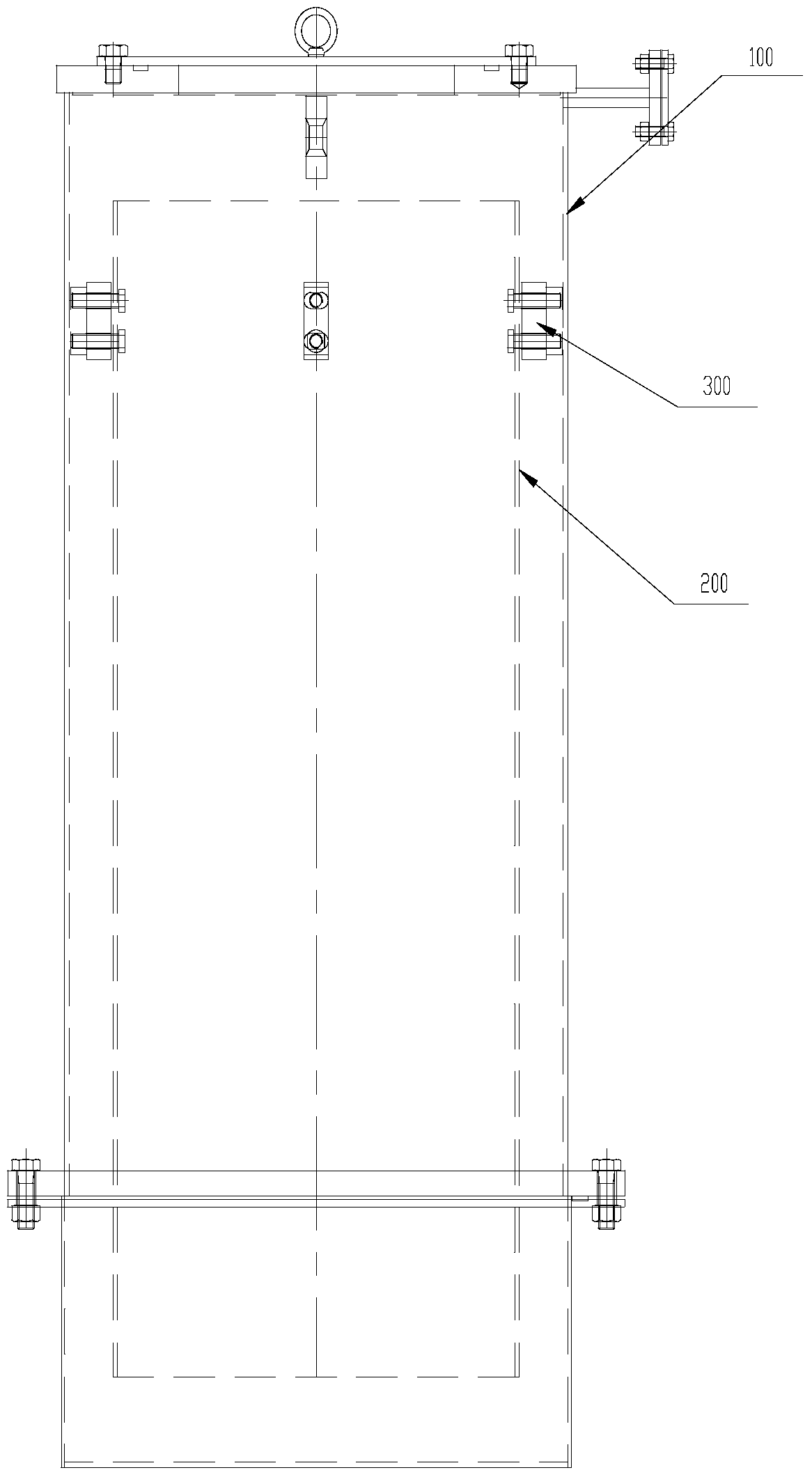

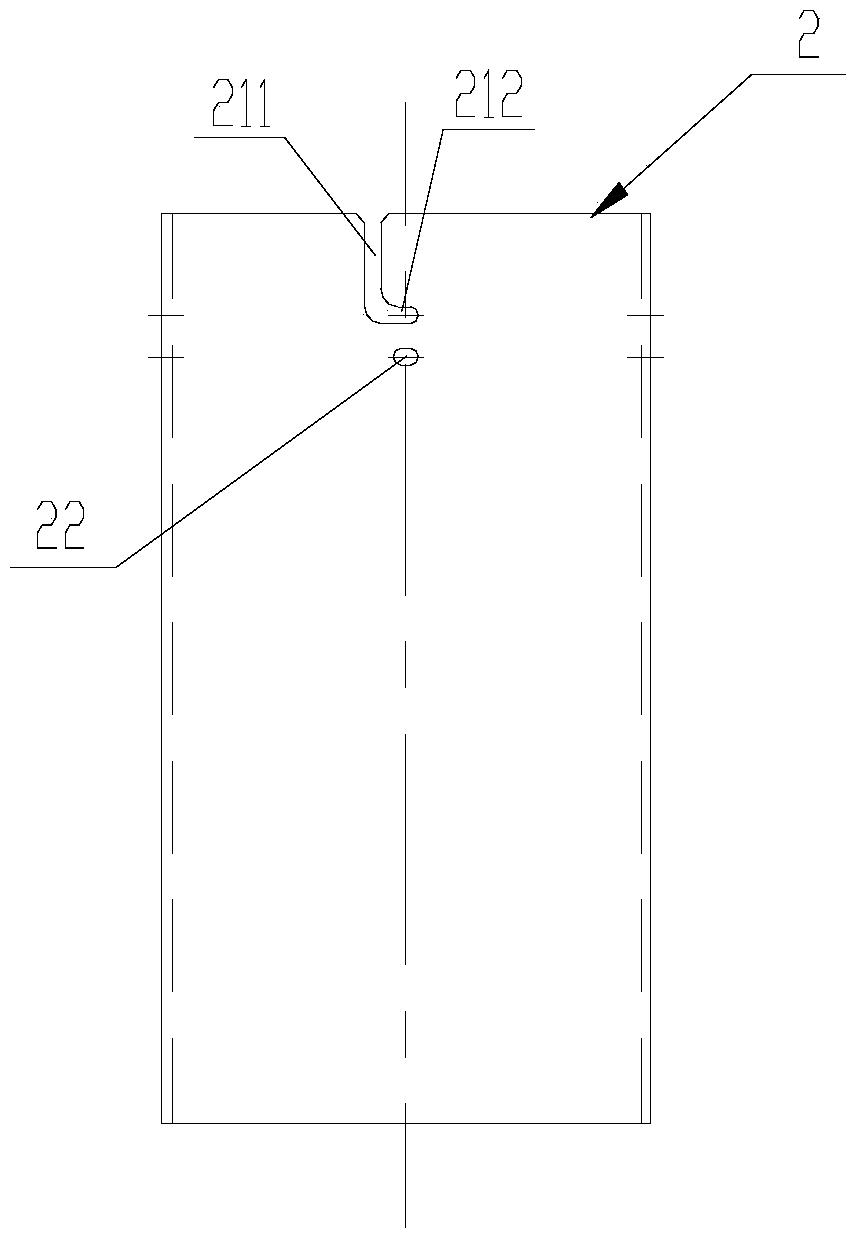

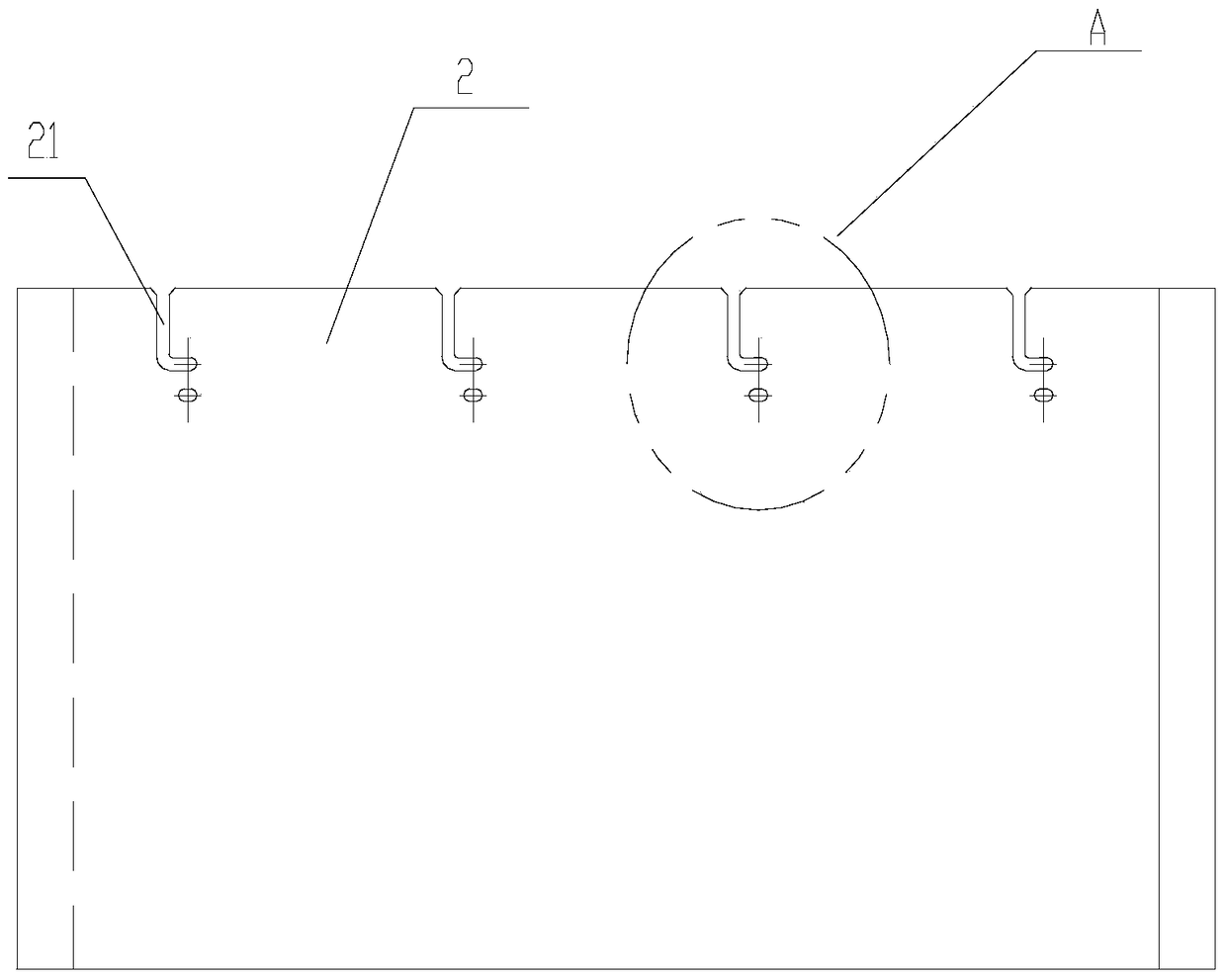

[0025] Such as Figure 2-7 As shown, an insulating cylinder and a transformer provided by the present invention include: a riser 1 , an insulating cylinder 2 , a spacer 3 and a fixing assembly 4 . The insulation cylinder 2 includes an insulation cylinder with a hollow interior, and the upper end of the side wall of the insulation cylinder has four open slots 21, each of which includes a vertical portion 211 and a limiting portion 212 obliquely intersecting with the vertical portion 211, and One end of the vertical part 211 extends to the upper surface of the insulating cylinder; the spacer 3 is provided with a through hole 31; the fixing assembly 4 includes a first insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com