Filtering device for liquid level measurement and control of flotation cell

A flotation cell and filter bubble technology, applied in the direction of liquid level control, non-electric variable control, control/regulation system, etc., can solve the problems of forgetting to adjust the valve, affecting the efficiency of mineral processing, poor precision, etc., to eliminate vibration and achieve good results , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

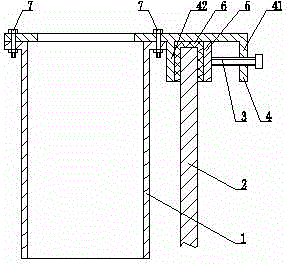

[0007] see figure 1 , the present invention includes a filter cartridge 1 and a flotation cell 2, and also includes a screw 3, a filter cartridge holder 4, a movable platen 5, a shock-absorbing rubber 6 and a bolt 7, and the lower right part of the filter cartridge holder 4 is provided with an outer Baffle 41 and positioning plate 42, the screw 3 is installed on the outer baffle 41, the filter cartridge 1 is connected with the filter cartridge fixing seat 4 through the bolt 7, and the positioning plate 42 of the filter cartridge fixing seat 4 is placed on the floating Select the inner side of the tank 2, the outer baffle 41 of the filter cartridge holder 4 is placed outside the flotation tank 2, the movable pressure plate 5 is installed between the right side wall of the flotation tank 2 and the outer baffle 41, And the movable pressing plate 5 is compressed by the screw 3 , and the shock-absorbing rubber 6 is installed between the outer baffle plate 41 and the movable pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com