An air conditioner outdoor unit tray

A technology for air-conditioning outdoor units and trays, which is applied in air-conditioning systems, space heating and ventilation, and space heating and ventilation details. The effect of high sum height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

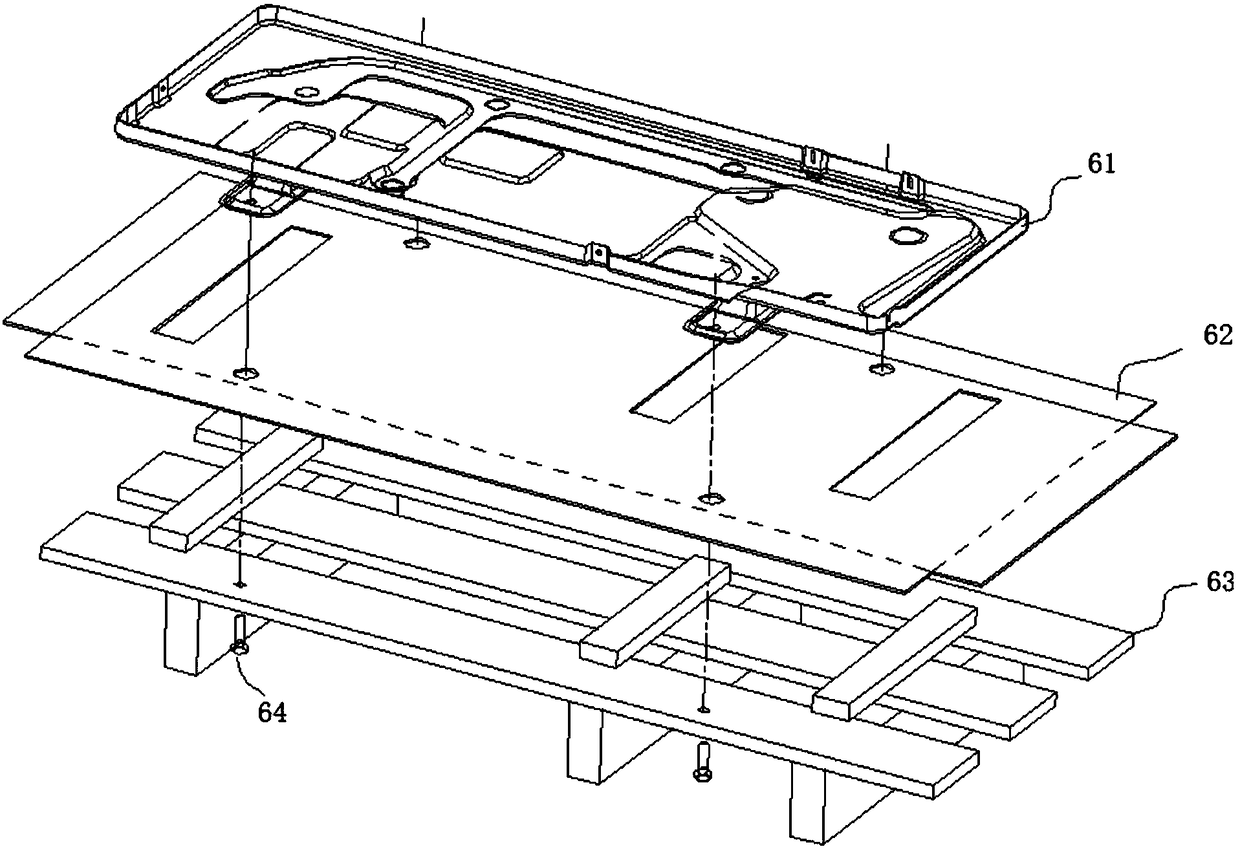

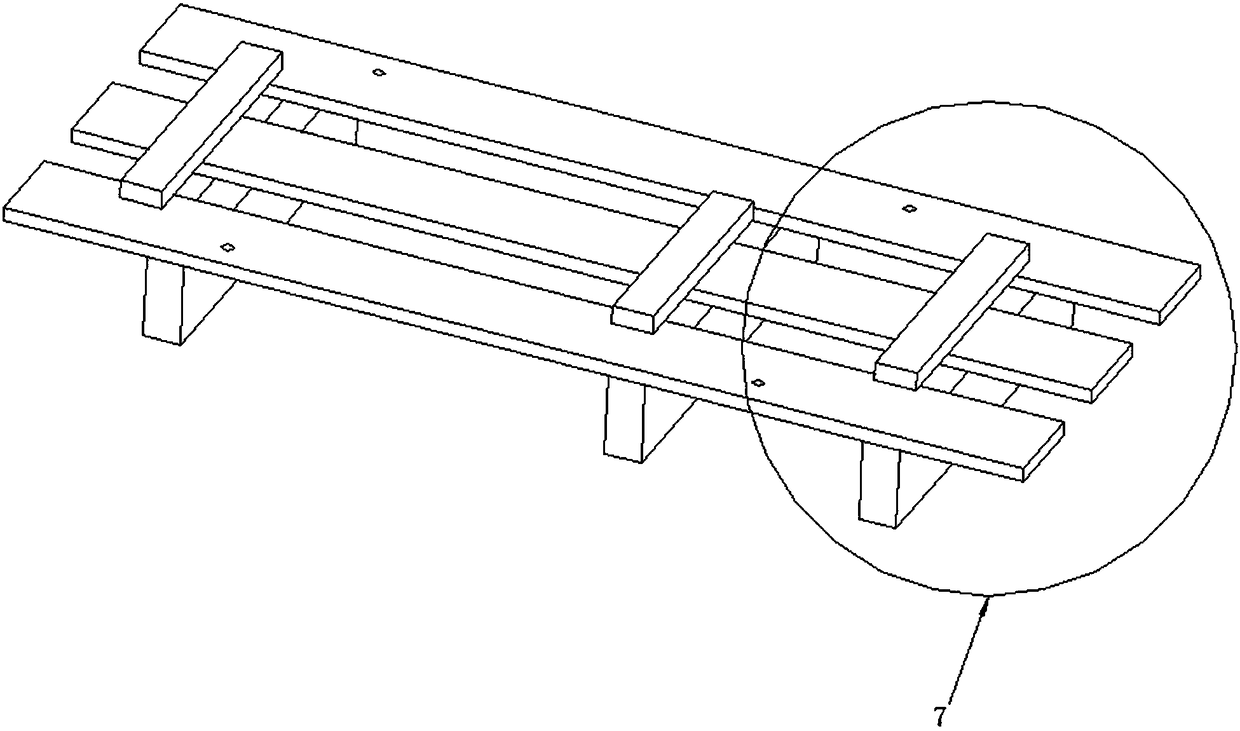

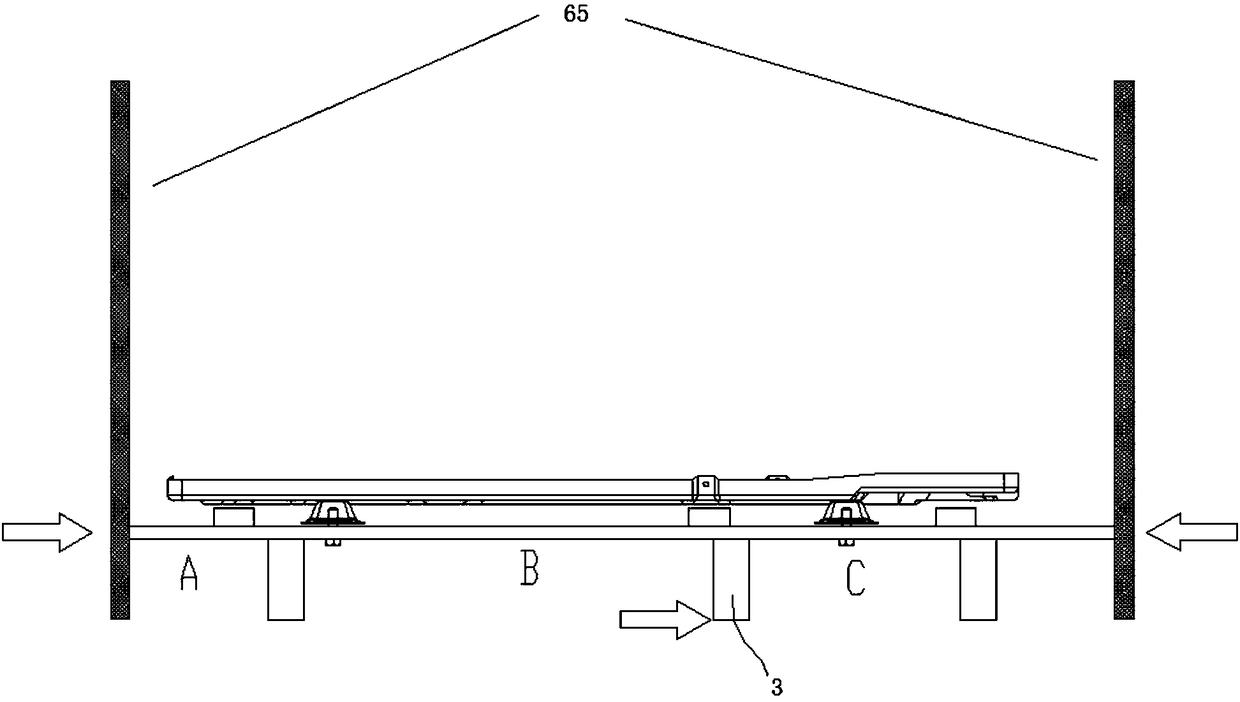

[0050] Such as Figure 8 As shown, an embodiment of the present invention provides an air conditioner outdoor unit tray, which generally includes a sleeper 1 , an upper plank 2 , a beam 3 and a lower plank 4 . The crossties 1 are placed on the upper plank 2 . The beam 3 is used to support the upper deck 2 , which includes a first set of beams 31 and a second set of beams 32 respectively arranged under the upper deck 2 and located at both ends of the upper deck 2 . The lower deck 4 comprises a first lower deck 41 and a second lower deck 42, the first lower deck 41 is connected to the lower end of the first set of beams 31; the second lower deck 42 is connected to the lower end of the second set of beams 32; the first lower deck 41 and the lower end of the second set of beams 32; The gap between the second lower decks 42 is not smaller than the fork width of the forklift.

[0051] The air-conditioning outdoor unit tray described in this embodiment combines the characteristics ...

Embodiment 2

[0060] The air conditioner outdoor unit tray provided by another embodiment of the present invention is as follows: Figure 11 , Figure 12 , Figure 13 shown in . In order to facilitate the use of forklifts, organic foot fixing holes 5 are arranged on the upper deck. The machine foot fixing hole 5 is located between the second beam 312 and the third beam 321 . The air-conditioning outdoor unit tray of this design has a relatively large distance between the second beam 312 and the third beam 321, that is, the width of the passage for the fork of the forklift to pass through is wider, and the use of the fork is more convenient. At the same time, due to the increase of the width, The requirement for the strength of the upper deck also increases accordingly, and the method of increasing the strength of the upper deck can be achieved by increasing the strength of the upper deck material or by using a double-layer upper deck, as described in the following examples.

[0061] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com