Oil supply device, scroll compressor with oil supply device and control method

A scroll compressor and oil supply device technology, applied in the field of compressors, can solve the problems of uncontrollable oil supply, oil supply passages that cannot adjust the oil supply according to the speed, etc., and achieve the effect of stable oil supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

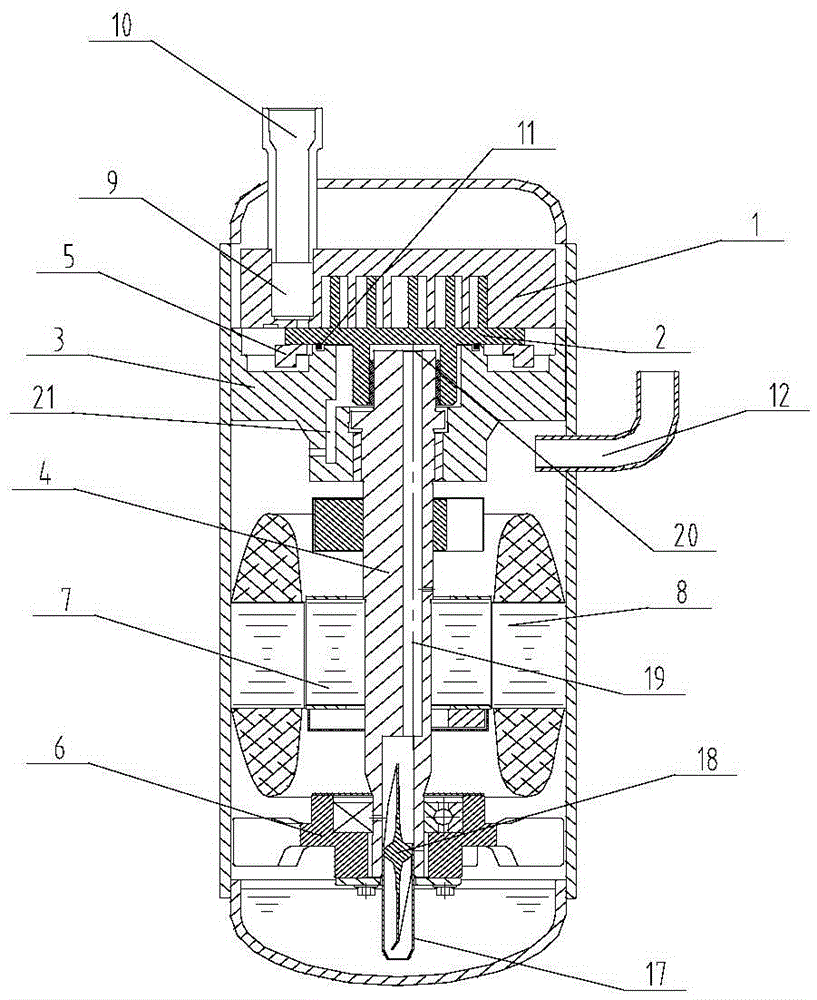

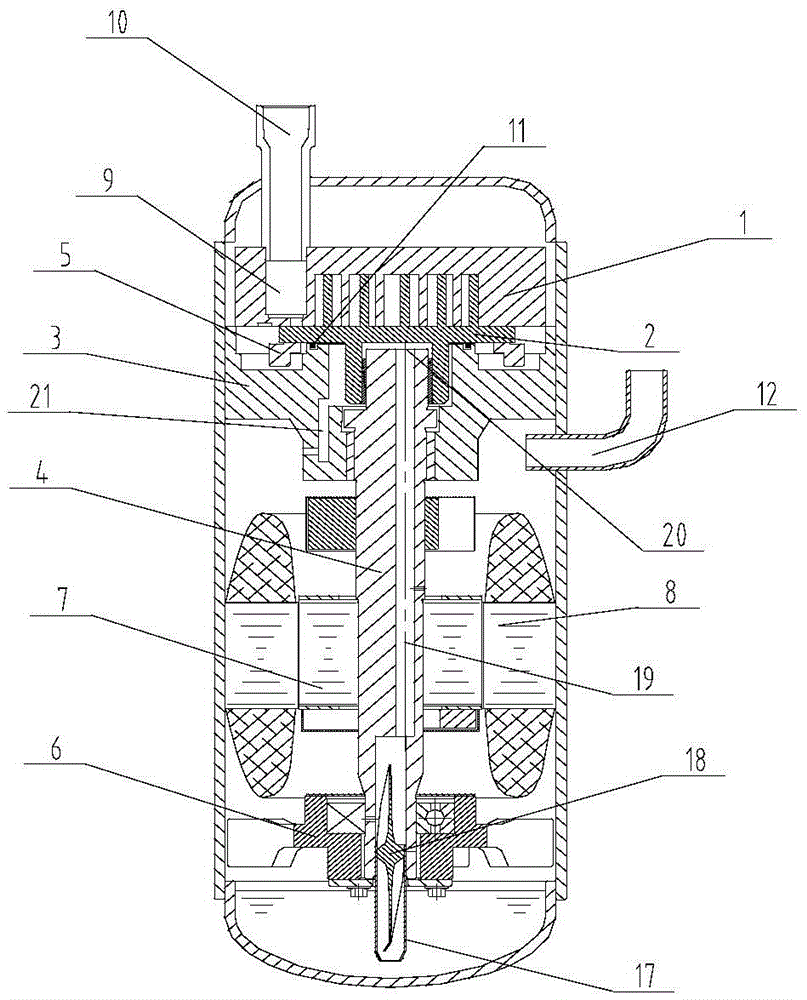

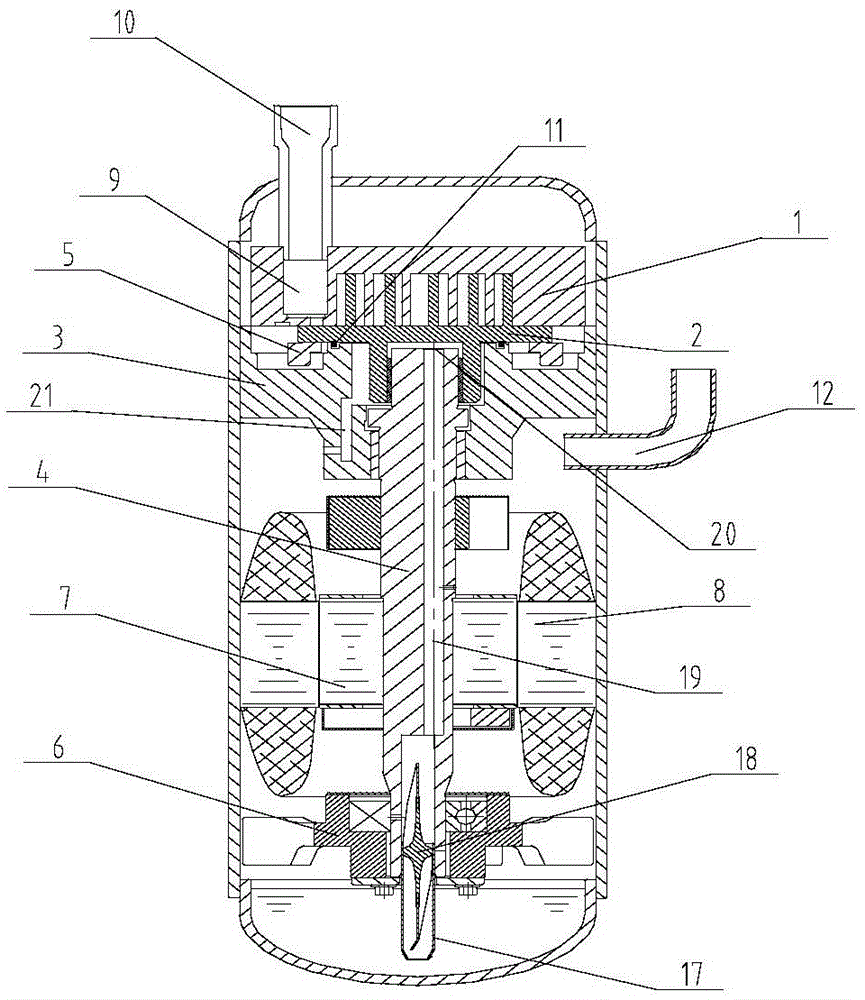

[0037] Such as Figure 4-6 As shown, the present invention provides an oil supply device, including a rotating part 2, a back pressure oil pool arranged at the lower end of the rotating part 2, and a back pressure oil pool arranged inside the rotating part 2 and capable of communicating with the back pressure The oil supply passage 15 between the oil pool and the upper end surface of the rotating part 2, and the oil supply passage 15 arranged in the oil supply passage 15 can be controlled to open, close or close the oil supply passage 15 according to the speed of the rotating part 2 A control mechanism that adjusts the size of the conduction opening.

[0038] Through the control mechanism provided in the oil supply passage of the present invention that can control the oil supply passage to be turned on, closed or adjust the conduction opening according to the size of the rotational speed of the rotating component, it can be used especially for scroll compressors. The amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com