Compressor

A compressor and main bearing technology, applied in the field of compressors, can solve the problems of easy deformation due to heat, shorten the service life of the motor, serious wear, etc., and achieve the effect of solving the gap between the stator and rotor, reducing the processing difficulty and improving the assembly accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

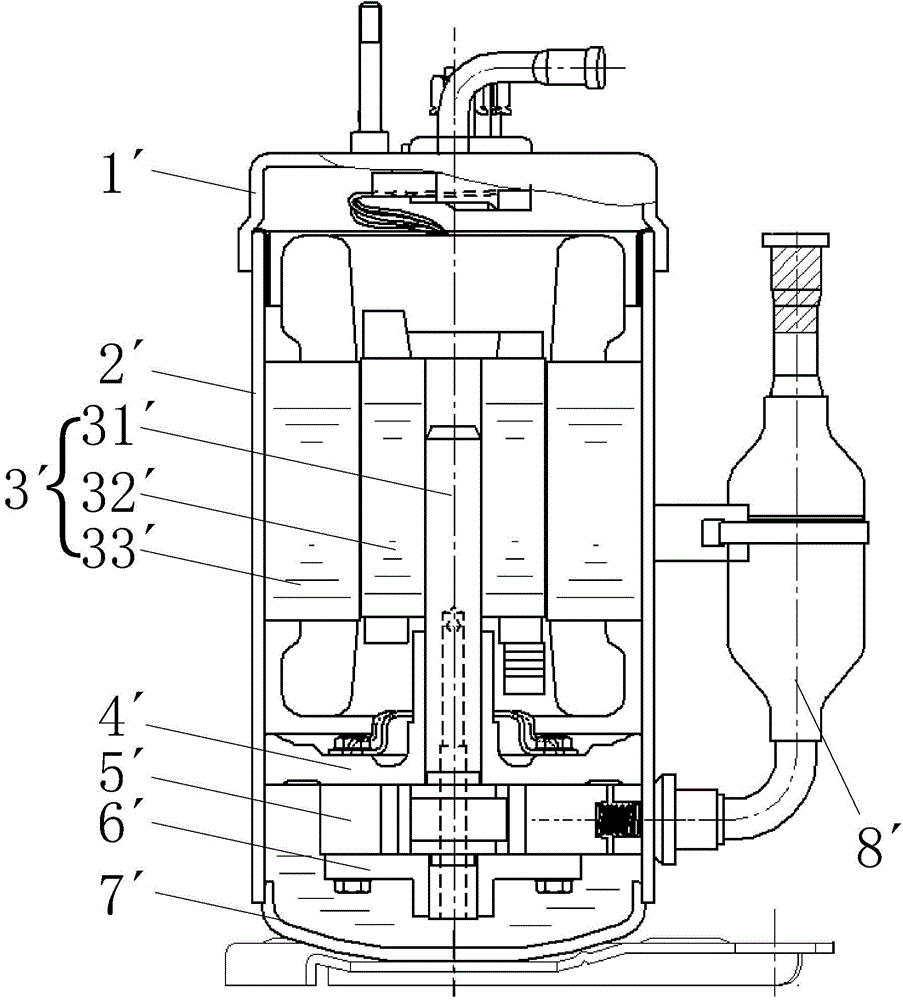

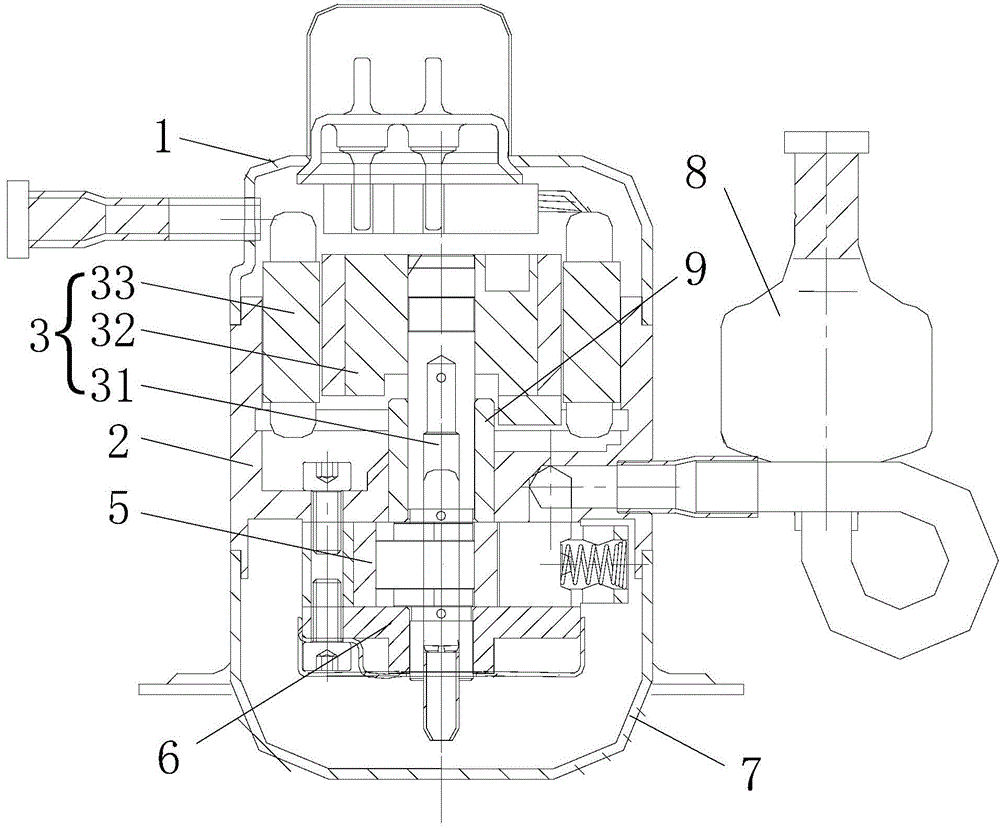

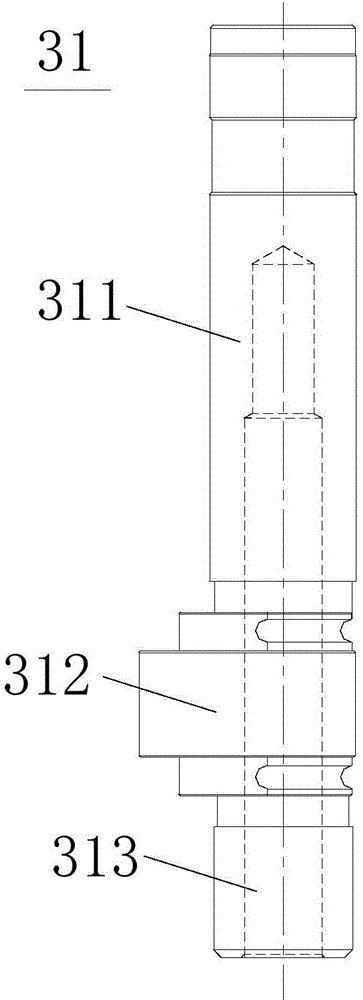

[0080] Such as figure 2 and image 3 As shown, the micro-compressor of the present invention includes: a housing; the motor 3 is accommodated in the upper space in the housing; the cylinder 5 is accommodated in the lower space in the housing; the crankshaft 31 has a long axis portion 311 and an eccentric portion 312 and short axis portion 313 (such as image 3 As shown), the rotational force of the motor 3 is transmitted to the cylinder 5 to compress the refrigerant; the first bearing assembly and the second bearing assembly together define the compression space with the cylinder 5 and support the crankshaft 31, wherein the first bearing assembly includes at least Upper bearing (ie main bearing) 2 and bushing 9, upper bearing 2 is located between motor 3 and cylinder 5. The second bearing assembly includes at least a lower bearing (ie a secondary bearing) 6 .

[0081] Such as Figure 4 As shown, the upper bearing 2 has a disc portion 21 with a through hole 24, an inner ed...

no. 2 example

[0093] Such as Figure 7 As shown, in a modification example, the upper bearing 2a may also be a disc portion 21a with a through hole 24a and an outer edge portion extending up and down from the outer edge of the disc portion 21a, and the middle cross section of the upper bearing 2a as a whole is H shape. The height of the bushing 9a matched with the upper bearing 2a is greater than or equal to the thickness of the disc portion 21a. and Figure 4 and Figure 5 The first embodiment shown differs in that, as Figure 7 The inner edge portion 25 of the upper bearing 2 has been canceled in the upper bearing 2a (see Figure 5 ). After canceling the inner edge portion 25, the main part of the upper bearing 2a becomes a simple planar structure (disc portion 21a), and the processing becomes easier, and the inner circular surface of the through hole 24a of the upper bearing 2a is no longer used for matching , the machining accuracy is also reduced, therefore, the overall machining...

no. 3 example

[0095] Such as Figure 8 As shown, in a variation example, with Figure 4 and Figure 5 Unlike the first embodiment shown, Figure 8 The inner edge portion 25b of the upper bearing 2b is shown as an inner cylindrical shape protruding from the disc portion 21b. The inner circular surface of the through hole 24b is jointly constituted by the inner peripheral surface of the disc portion 21b and the inner peripheral surface of the inner edge portion 25b. Moreover, the height of the bushing 9b is equal to the sum of the thicknesses of the disk portion 21b and the inner edge portion 25b, so that the inner circular surface of the through hole 24b (the inner peripheral surface of the disk portion 21b and the inner peripheral surface of the inner edge portion 25b) is more compact. Well support the bushing 9b. Similarly, the inner circular surface of the through hole 24b of the upper bearing 2b is no longer used for matching, therefore, the overall processing difficulty of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com