Energy-saving anti-deformation solid wood door edge and door head

An anti-deformation, solid wood technology, applied in the direction of windows/doors, wing frames, building components, etc., can solve the problems of wasting wood resources, cracking, deformation, etc., to maintain overall beauty, large market demand, and good development prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

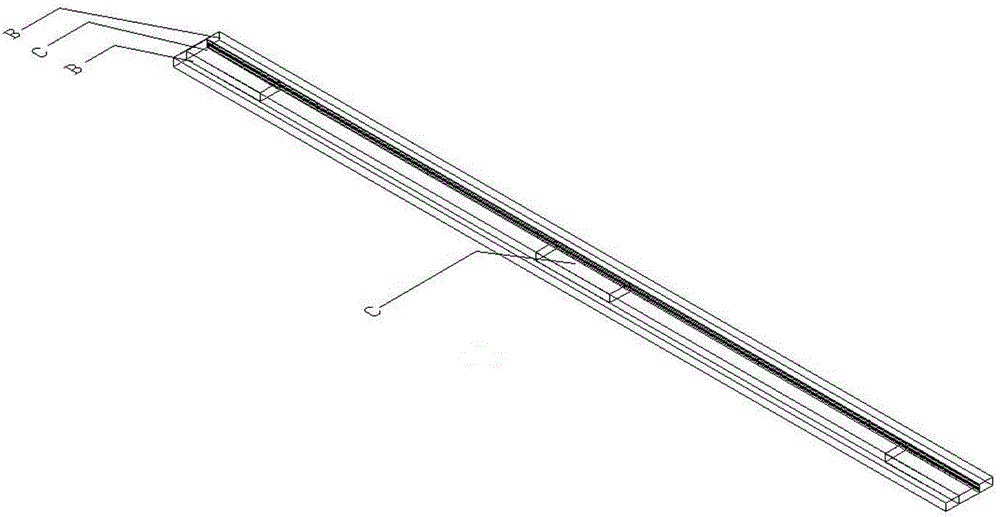

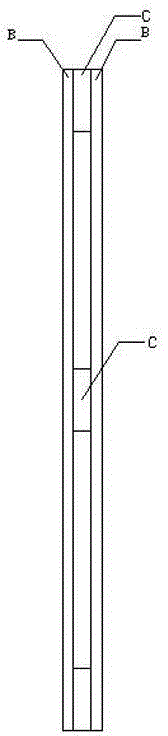

[0018] An energy-saving and anti-deformation solid wood door edge and dock, including a door edge panel, a door frame, and a door frame end frame, characterized in that: the door frame is located on both sides of the door frame end frame, and the door edge panel covers the door frame and the door frame end frame superior.

Embodiment 2

[0020] The door frame is the same length as the door side panel, and the end frame of the door frame is shorter than the door frame and the door side panel.

Embodiment 3

[0022] The length of the end frame of the door frame is at least 100mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com