Steering pump body belt wheel assembling equipment

A technology for assembling equipment and steering pumps, applied in metal processing equipment, transportation and packaging, metal processing, etc., can solve the problems of inability to withstand the direct pressure of the press and the inapplicability of the press. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

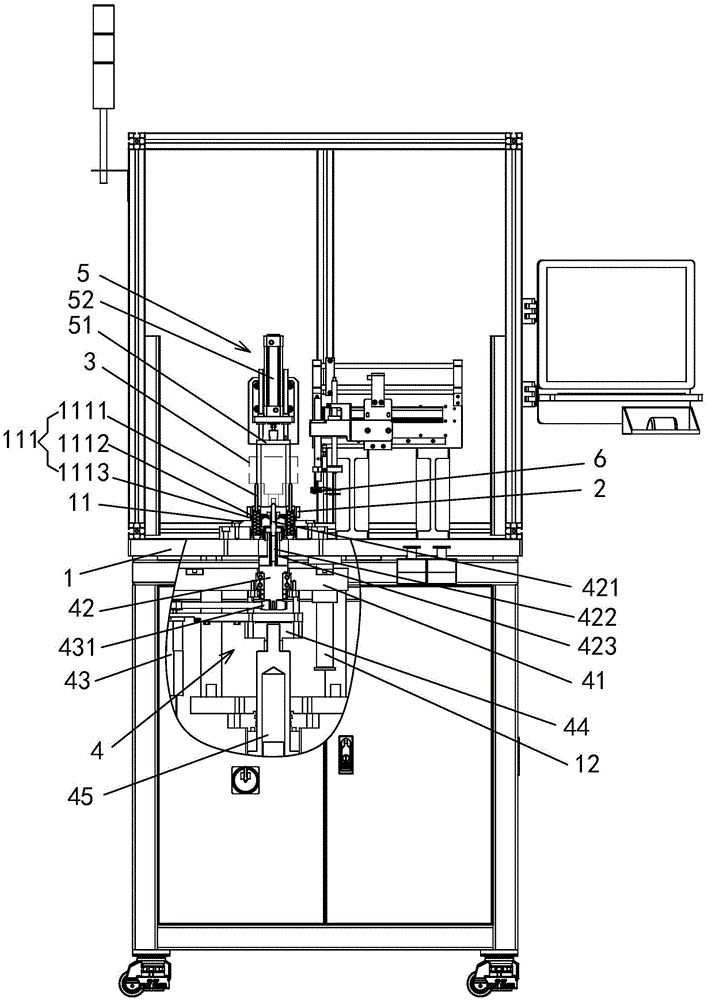

[0013] Example: see figure 1 Shown:

[0014] A steering pump body pulley assembly equipment, see figure 1 As shown, it includes a worktable 1, on which a positioning tool 11 is fixed, on which the pulley 2 and the pump body 3 are placed sequentially from bottom to top. The positioning tool 11 positions the pulley 2 and the pump body 3, keeps the pulley 2 on the bottom, the pump body 3 (drawn by a dotted line in the figure) on the top, and the rotating shaft of the pump body 3 is opposite to the central hole of the pulley 2 The position state ensures that the pulley 2 cannot move downward relative to the worktable, while the pump body 3 can move downward relative to the worktable.

[0015] see figure 1 As shown, a pull-down device 4 is provided under the worktable 1 , and the pull-down device 4 includes a vertically moving seat 41 , a central rotating shaft 42 , a rotary drive device 43 , a tension sensor 44 and a vertical drive device 45 . The up and down moving seat 41 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com