an automatic cooking machine

An automatic cooking and automatic technology, applied in the direction of cooking utensils, household appliances, applications, etc., can solve the problems of artificial side dishes, and achieve the effect of increasing efficiency, improving the efficiency of serving dishes, and simple and labor-saving operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

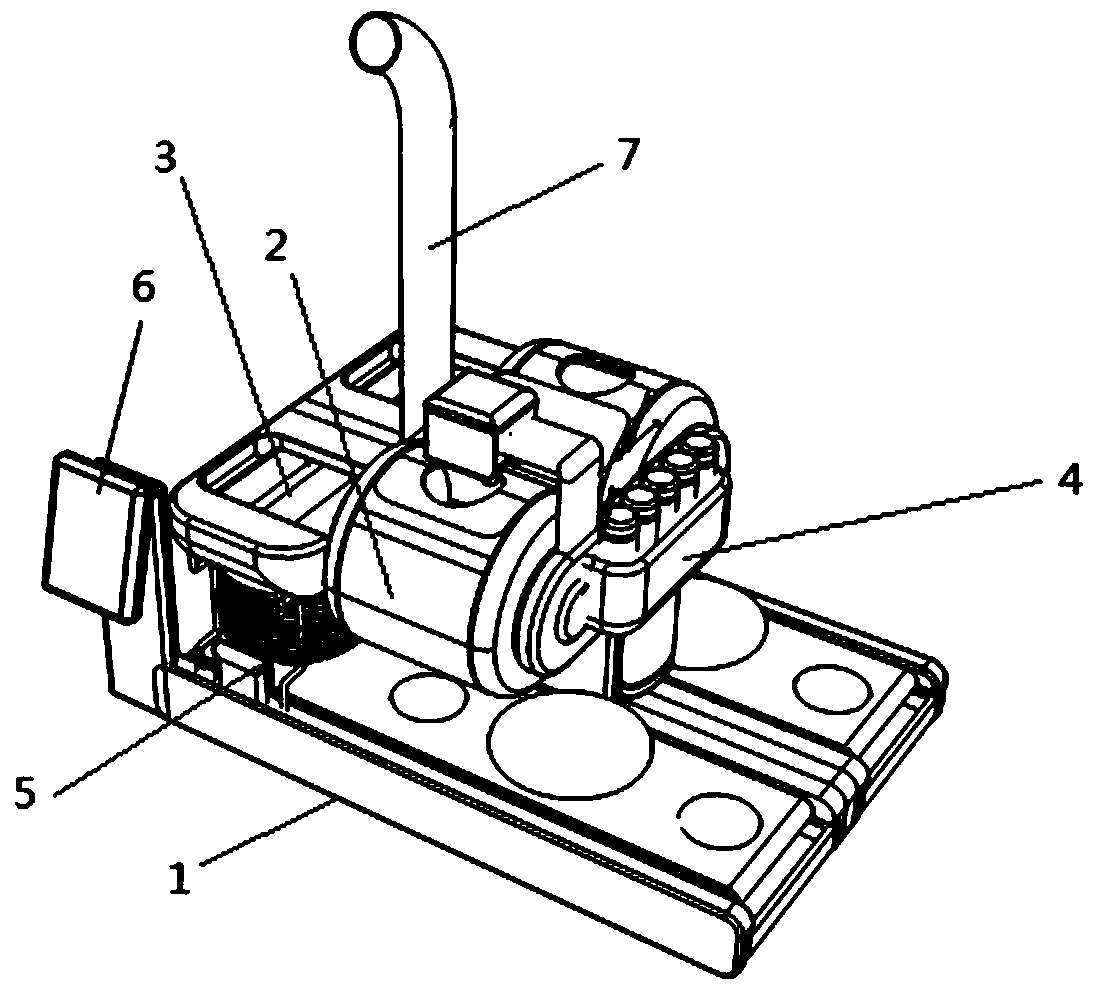

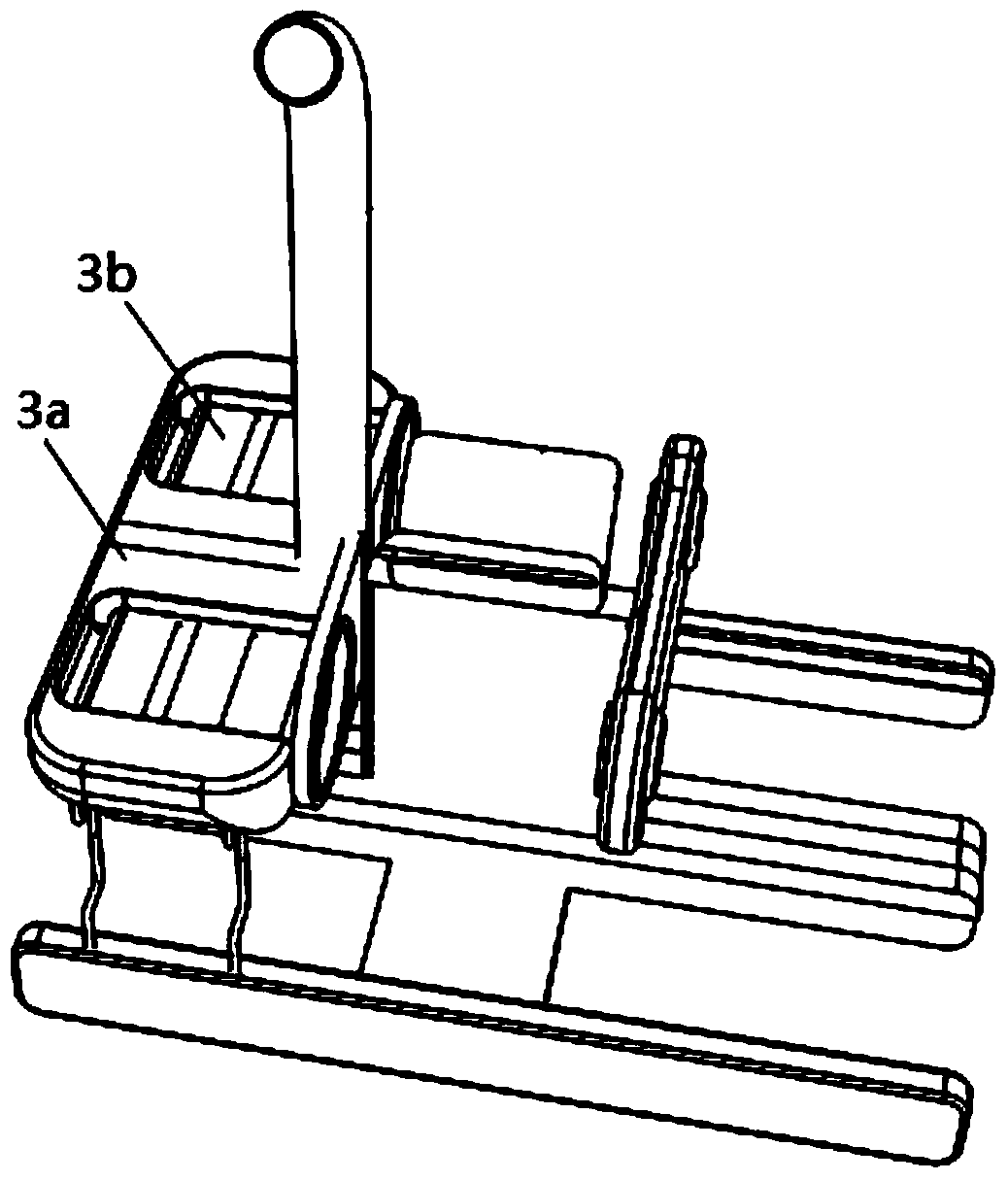

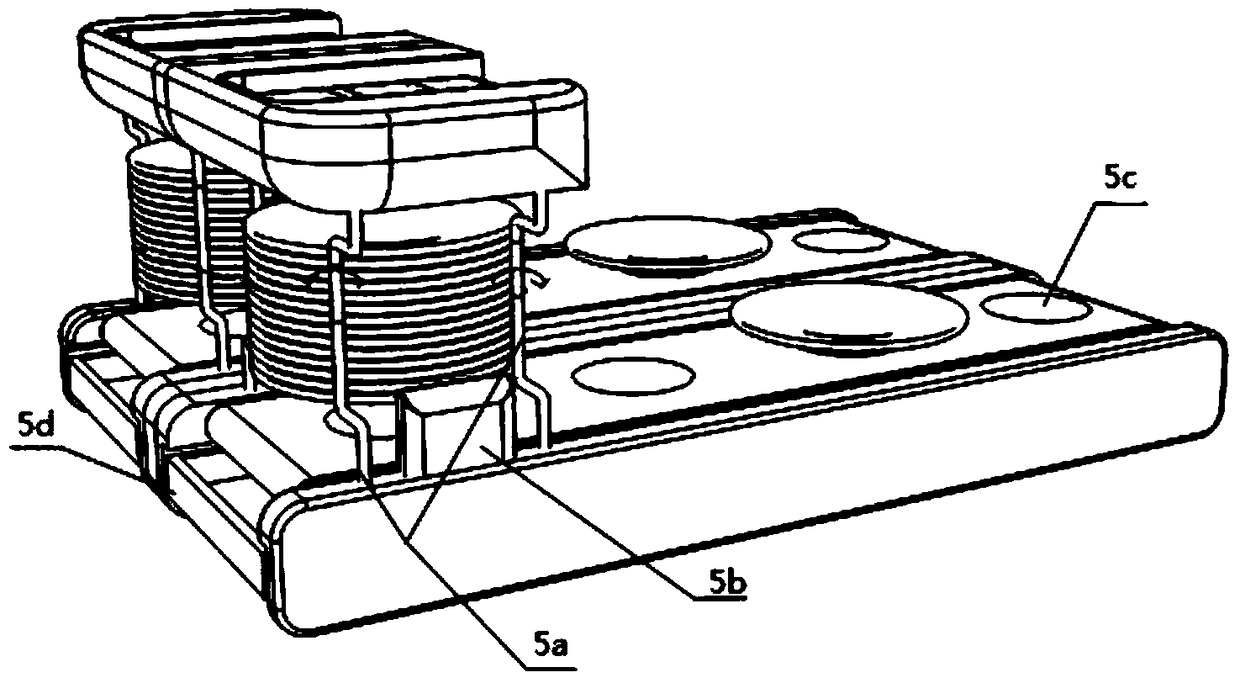

[0047] Figure 1 to Figure 11 A specific embodiment of the automatic cooking machine of the present invention is shown, which includes a frame 1 on which a cylindrical frying pan 2, a dish-serving mechanism 3, a batching mechanism 4, and an automatic plate-loading mechanism 5 are arranged. , PLC controller and human-computer interaction panel6. Wherein: the tubular wok 2 is provided with a vegetable inlet 2a, a vegetable inlet sealing cover 2b for opening / closing the vegetable inlet, a vegetable outlet, and a vegetable outlet for opening / closing the vegetable outlet A port closing cap, a material inlet 2e, and a material inlet closing cap 2f for opening / closing the material inlet. The dispensing mechanism 3 is used to weigh the dishes, and deliver the dishes to the dish inlet 2a of the cylindrical wok. The batching mechanism 4 is used for storing seasonings and can send the seasonings to the material inlet 2e of the cylindrical wok. The automatic plate loading mechanism 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com