How to make anti-gravity water cup

A production method and anti-gravity technology, which is applied to drinking vessels and other directions, can solve the problems of water cups’ aesthetic impact, broken cups, and easy dents on the surface of water cups.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below by means of specific embodiments:

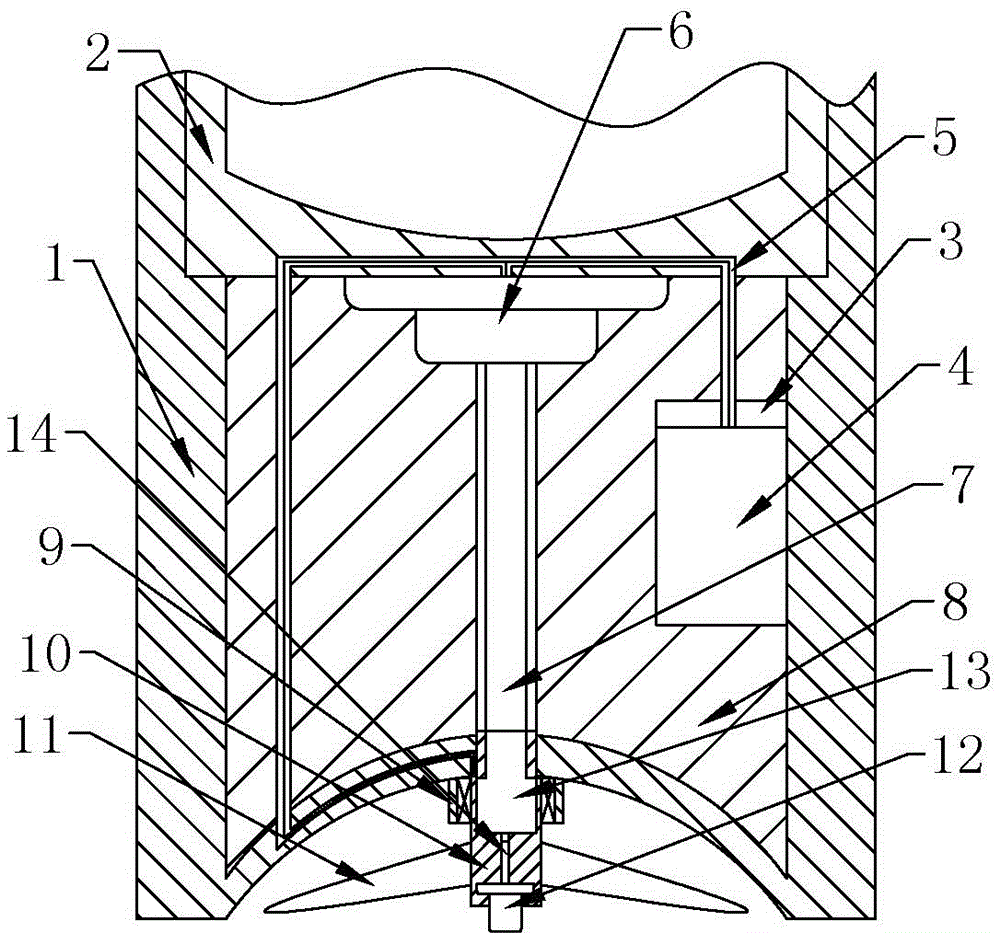

[0025] The reference signs in the drawings of the specification include: cup body 1, cup liner 2, cavity 3, battery 4, wire 5, fan switch 6, screw rod 7, support block 8, sleeve 9, rotating shaft 10, fan blade 11, Control switch 12, connection block 13, push rod 14.

[0026] Example basic reference figure 1 Shown: the manufacturing method of the anti-gravity water cup, comprising the following steps:

[0027] A. Injection molding: The cup body 1, the support block 8 and the cup liner 2 are respectively injection molded by the injection molding machine, and the outer side of the bottom of the cup body 1 is set into a concave arc, and the concave arc is the first groove;

[0028] B. Grooving: using a slotting machine, open a cavity 3 and the second groove on the support block 8, open a square opening at the lower end of the screw 7 and the top of the fan shaft 10, and ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com