Valve bag

A valve pocket and cement technology, applied in the field of valve pockets, can solve problems such as high production costs and achieve the effect of simple strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

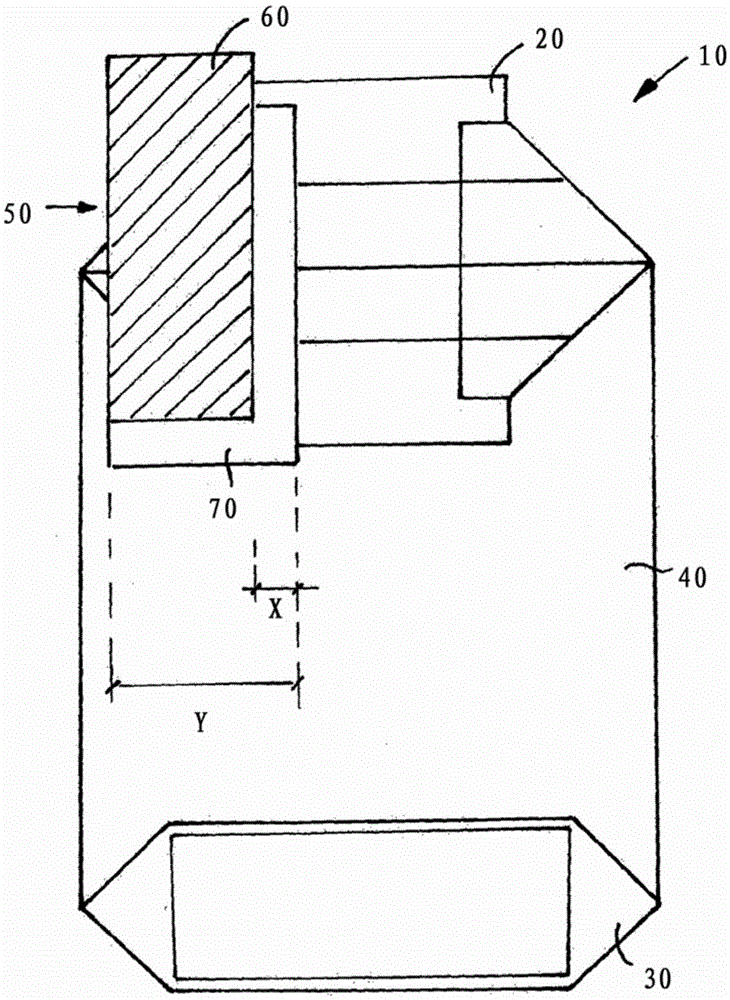

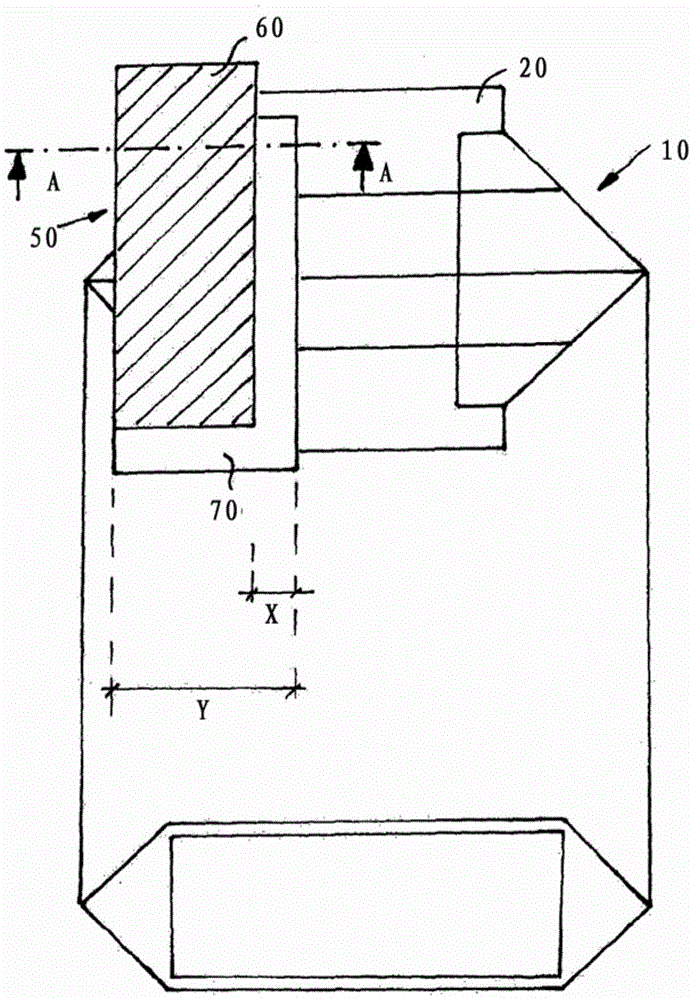

[0020] figure 2 The diagrams of the figure show the valve pocket according to the invention with the thermal material used for the shortening according to the invention. Apart from the modified valve hose, the design of the valve pocket largely corresponds to the solutions known from the prior art.

[0021] The figures show a valve bag 10 according to the invention, which has an upright bottom 20 folded forward at the lower end and a valve bottom 30 at the upper end. Both bases 20 , 30 are connected to each other via a front side 40 and a rear side (not shown) and are folded in the shape of a cross base. In order to illustrate the valve structure, the valve base 20 is shown unfolded, but opened.

[0022] Similar to the prior art, the valve hose 50 protrudes from the upper and lower corners of the valve base 20 on the left side of the valve base. The valve hose 50 here also consists of a thermal material 60 such as a weldable plastic material and a carrier material 70 such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com