Step-peristaltic drive excitation method based on bending motion of multi-piezoelectric vibrator

A piezoelectric vibrator, driving excitation technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. Stroke and other issues, to achieve the effect of flexible output motion form, high positioning accuracy, and large output displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

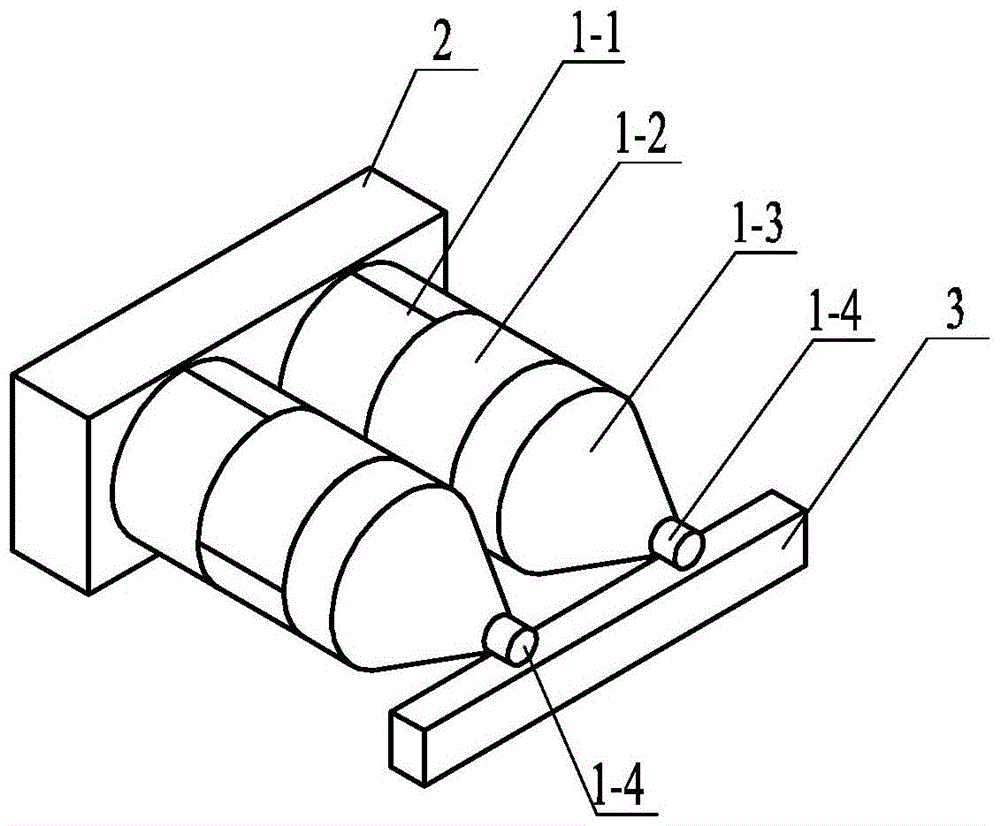

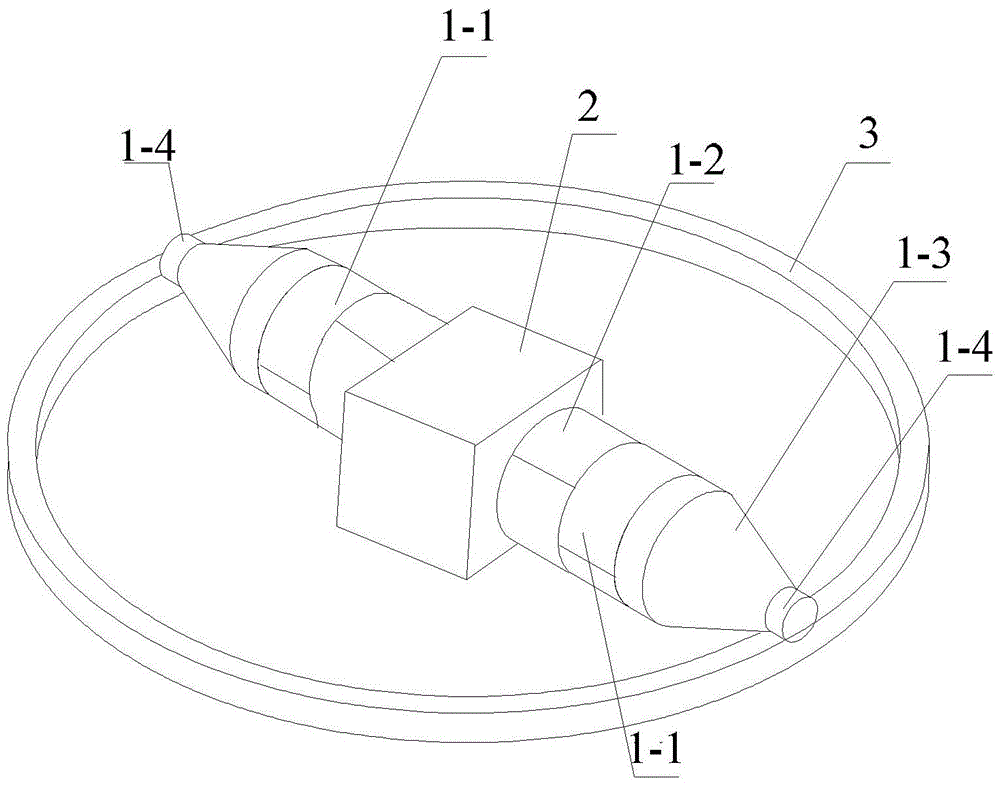

[0064] Specific implementation mode one: refer to figure 1 , image 3 , Figure 4 and Figure 5 Specifically explain this embodiment, the step-peristal driving excitation method based on the bending motion of multiple piezoelectric vibrators described in this embodiment, this method requires n piezoelectric vibrators arranged in parallel, n is a positive integer, and n≥2; Each piezoelectric vibrator includes a horizontally curved ceramic group 1-1, a vertically curved ceramic group 1-2, a horn 1-3 and a driving foot 1-4;

[0065] The horizontal bending ceramic group 1-1 is composed of two piezoelectric ceramic halves that are horizontally buckled,

[0066] The vertical bending ceramic group 1-2 is composed of two piezoelectric ceramic half groups that are vertically buckled,

[0067] And the horizontal curved ceramic group 1-1 and the vertical curved ceramic group 1-2 are arranged concentrically,

[0068] The mover 3 is a cuboid structure,

[0069] One end of the horizon...

specific Embodiment approach 2

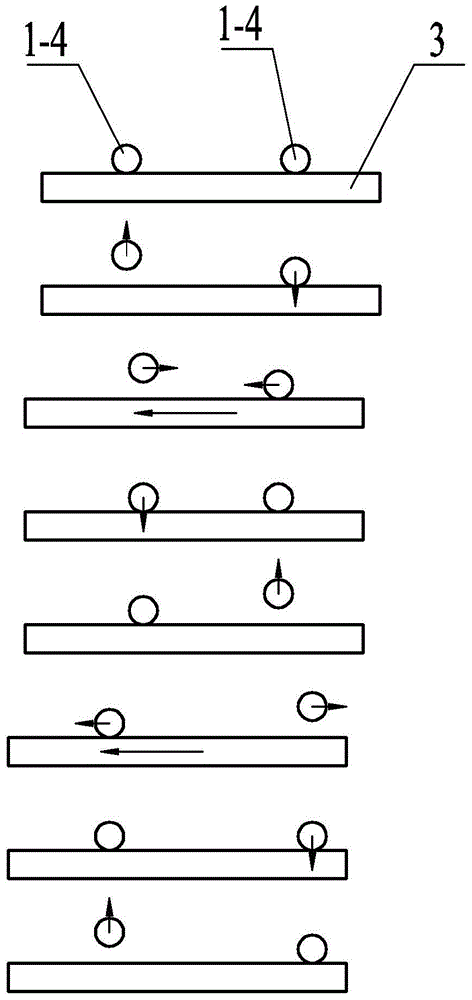

[0094]Specific embodiment 2: This embodiment is a further description of the step-peristal driving excitation method based on the bending motion of the multi-piezoelectric vibrator described in the specific embodiment 1. In this embodiment, the horizontal bending ceramic group 1-1 is applied When the same DC excitation voltage is applied, one of the two piezoelectric ceramic halves is elongated and the other is shortened; when the vertical bending ceramic group 1-2 is applied with the same DC excitation voltage, one of the two piezoelectric ceramic halves is elongated and the other is shortened. shorten.

specific Embodiment approach 3

[0095] Specific implementation mode three: refer to figure 1 , image 3 , Figure 4 and Figure 6 This embodiment will be specifically described. The step-peristal driving excitation method based on the bending motion of multiple piezoelectric vibrators described in this embodiment will be further described. In this embodiment, this method requires n piezoelectric vibrators arranged in parallel, and n is A positive integer, and n≥2; each piezoelectric vibrator includes a horizontally curved ceramic group 1-1, a vertically curved ceramic group 1-2, a horn 1-3 and a driving foot 1-4;

[0096] The horizontal curved ceramic group 1-1 and the vertical curved ceramic group 1-2 are reset along the axis of the piezoelectric vibrator 1, and the two piezoelectric ceramics of the horizontal curved ceramic group 1-1 are arranged between the horizontal curved ceramic group 1-1 and the vertical The left and right two quarters and a half of the structure formed by the curved ceramic group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com