Locking reset mechanism

A reset mechanism and locking technology, which is applied to the parts, electrical components, and flip/rocker switches of flip switches/rocker switches, etc., which can solve problems such as loss of spring components, complex structure, and damage to springs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

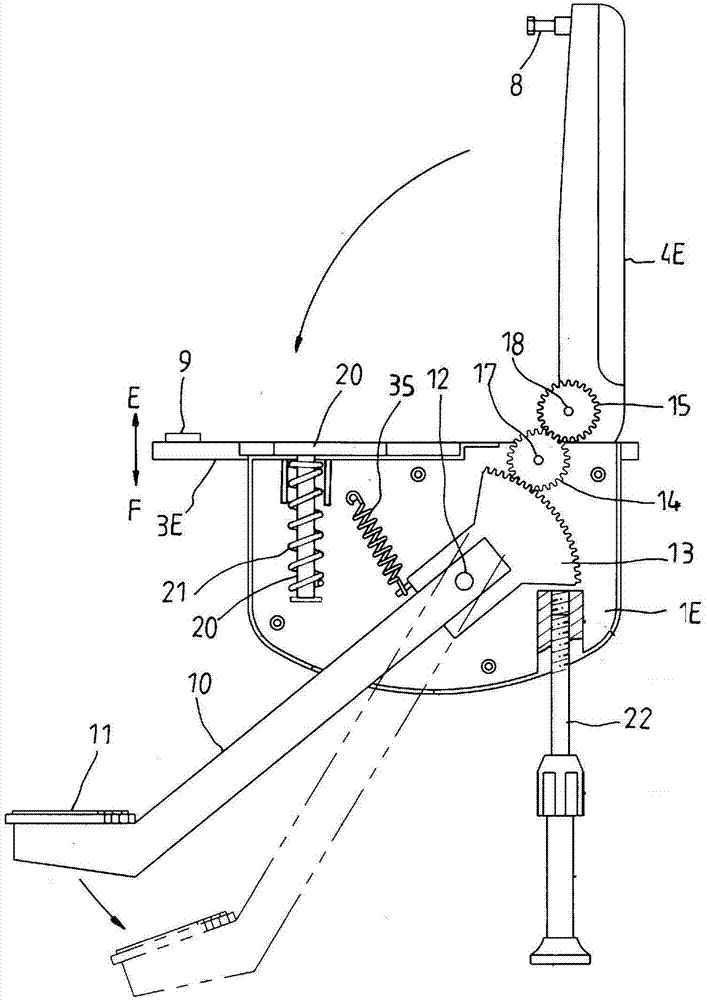

[0018] The reference signs in the accompanying drawings include: power rod 10, pedal 11, hinge point 12, limit rod 22, meshing teeth 13, rotating shaft 17, second gear 14, rotating gear 15, pin shaft 18, upper cover plate 19. Connecting column 20, buffer spring 21, return spring 35, support frame 1E, upper mold 8, lower mold 9, bottom plate 3E, cover plate 4E, E and F indicate the vertical direction relative to the lower mold, main spring 1, the second A secondary spring 2, a second secondary spring 4, a connecting column 3, and a steel column 5.

[0019] The embodiment is basically as attached figure 1 As shown: the lock reset mechanism in this embodiment includes a power rod 10, a support frame 1E, a bottom plate 3 and a cover plate 4E, and the bottom plate 3 is fixed on the support frame 1E. One end of the cover plate 4E is hinged to the base plate 3 , the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com