Compensator Optical System for Ultra High Precision Concave Aspheric Inspection

An optical system and aspheric surface technology, which is applied in the field of optical systems, can solve the problems of low detection accuracy of aspheric surface shape and non-common optical path measurement error, etc., and achieve the effect of improving detection accuracy, reducing error factors, and reducing design difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

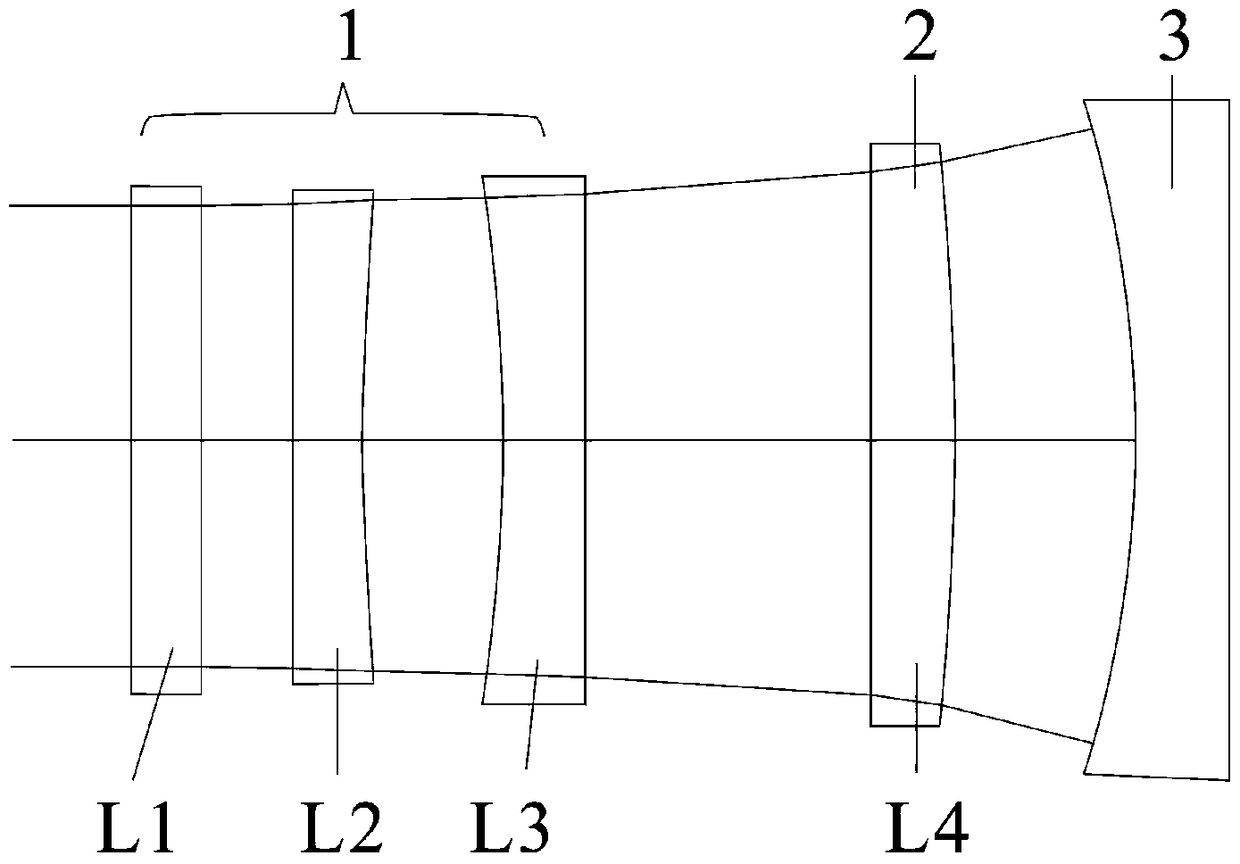

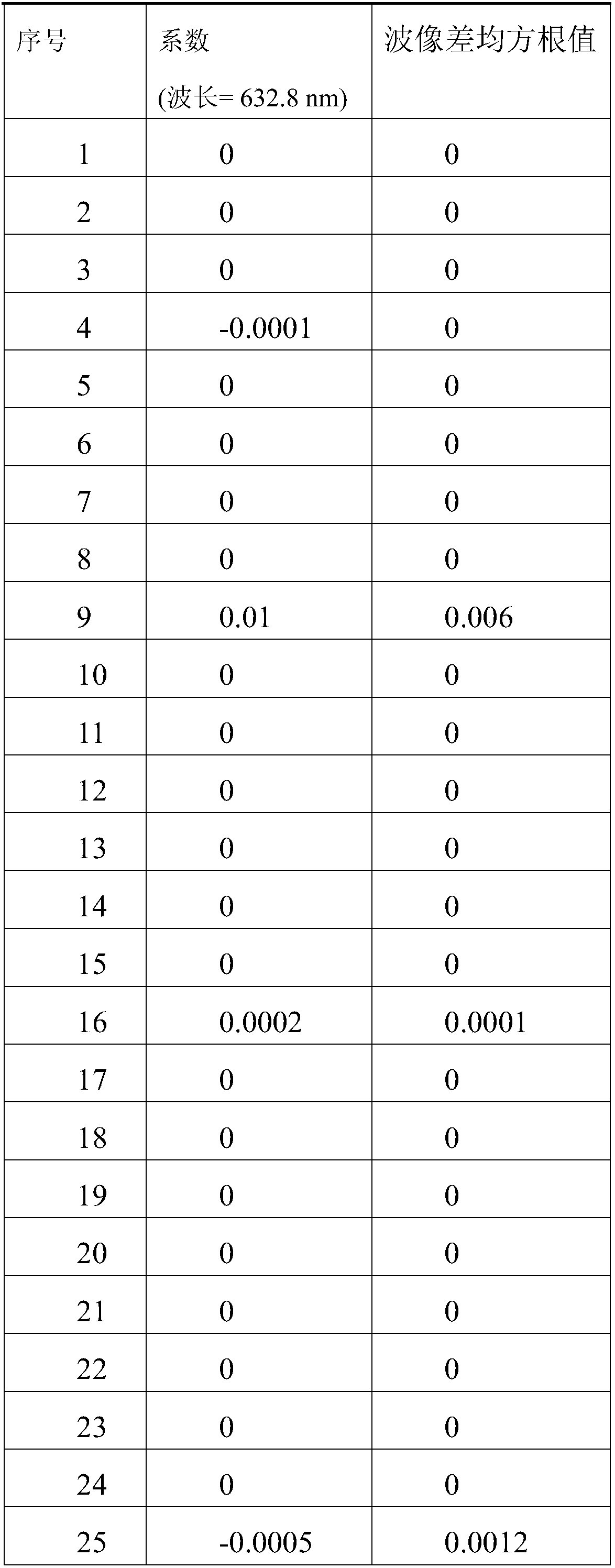

[0011] Specific implementation mode 1. Combination figure 1 and figure 2 In this embodiment, the compensator optical system for ultra-high-precision concave aspheric detection includes a transmission group 1 , a compensation group 2 and an aspheric concave mirror 3 to be inspected. The transmission group 1 provides transmitted spherical waves, and the compensation group 2 converts the spherical waves provided by the transmission group 1 into aspheric waves matching the aspheric concave mirror 3 to be tested. In order to improve the calibration accuracy and reduce the non-common optical path measurement error, the design value of the transmission spherical wave aberration of transmission group 1 is better than 0.005λRMS (λ@632.8nm); the F / # of the aspheric concave mirror 3 to be tested is 1.8, and the transmission group 1 The F / # of 1 is 3.1, and the F / # of compensation group 2 is 3.7, which can realize the ideal aberration compensation of the aspheric concave mirror compensa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com