Missile heavy-gravity tungsten alloy and preparation method thereof

A tungsten alloy and high specific gravity technology, which is applied in the field of high specific gravity tungsten alloys for elastics and the preparation of high specific gravity tungsten alloys for elastics, can solve the problems of uneven distribution of bonding phase, affecting performance stability, and many residual pores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

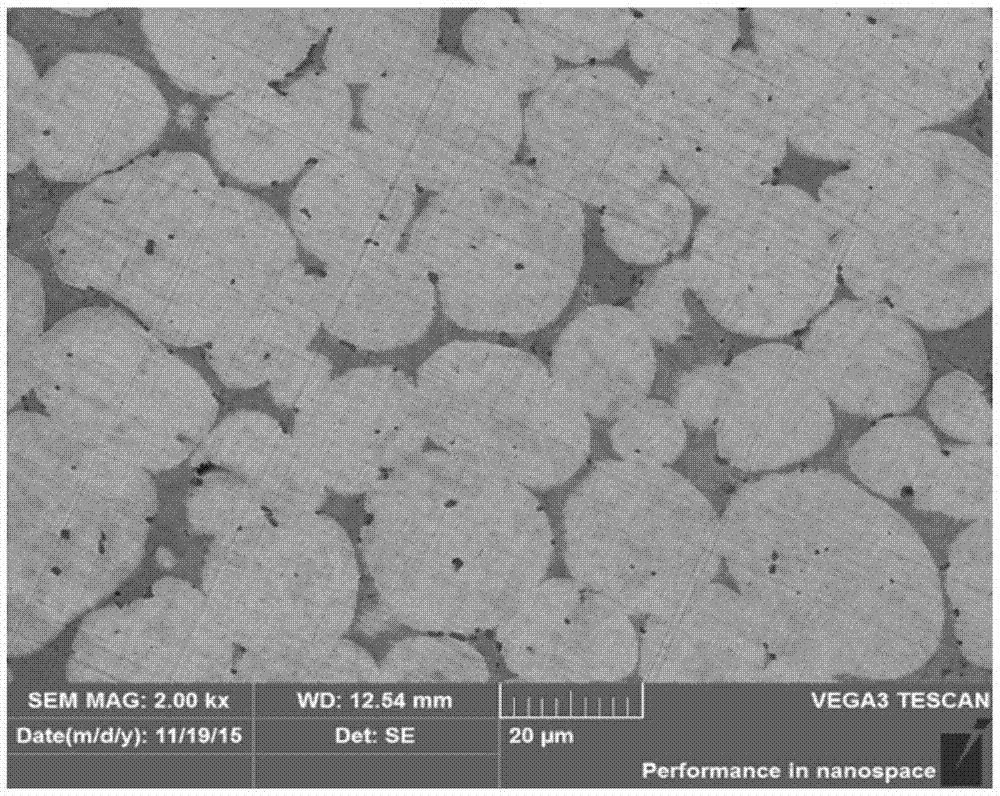

Image

Examples

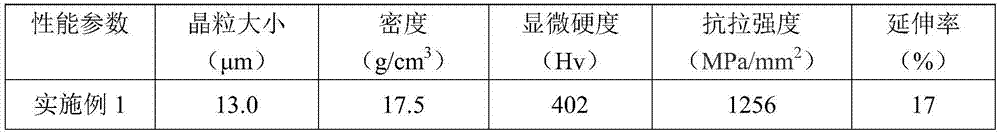

Embodiment 1

[0028] High specific gravity tungsten alloy for bullets, in mass percentage, the composition of the alloy is as follows:

[0029] Tungsten (W) 94.6%,

[0030] Zirconia (ZrO 2 )0.6%,

[0031] Nickel (Ni) 3.36%,

[0032] Iron (Fe) 1.44%,

[0033] and unavoidable impurities.

[0034] The preparation method of bullet with high specific gravity tungsten alloy (100kg), comprises the following steps:

[0035] 1) Preparation of zirconia-containing composite tungsten powder

[0036] Dissolve 129.68kg of ammonium metatungstate (the conversion rate of ammonium metatungstate into tungsten oxide powder is 92%) and 2.09kg of zirconium nitrate in water respectively, and then mix the two solutions evenly to obtain a mixed solution; take the mixed solution and evaporate to dryness to obtain The dry powder is calcined at a temperature of 500°C for 4 hours; the calcined product is put into a push rod reduction furnace and reduced in two stages, the temperature of the first stage of reducti...

Embodiment 2

[0044] High specific gravity tungsten alloy for bullets, in mass percentage, the composition of the alloy is as follows:

[0045] Tungsten (W) 91.7%,

[0046] Zirconia (ZrO 2 )0.2%,

[0047] Nickel (Ni) 5.67%,

[0048] Iron (Fe) 2.43%,

[0049] and unavoidable impurities.

[0050] The preparation method of bullet with high specific gravity tungsten alloy (100kg), comprises the following steps:

[0051] 1) Preparation of zirconia-containing composite tungsten powder

[0052] Dissolve 125.71kg of ammonium metatungstate and 0.70kg of zirconium nitrate in water respectively, and then mix the two solutions evenly to obtain a mixed solution; evaporate the mixed solution to dryness, and calcinate the obtained dry powder at a temperature of 400°C for 5 hours; put the calcined product in Put it into the push rod reduction furnace and divide it into two stages of reduction. The temperature of the first stage of reduction is 500°C, and the reduction time is 2 hours. The temperature...

Embodiment 3

[0060] High specific gravity tungsten alloy for bullets, in mass percentage, the composition of the alloy is as follows:

[0061] Tungsten (W) 92.9%,

[0062] Zirconia (ZrO 2 )0.8%,

[0063] Nickel (Ni) 4.41%,

[0064] Iron (Fe) 1.89%,

[0065] and unavoidable impurities.

[0066] The preparation method of bullet with high specific gravity tungsten alloy (100kg), comprises the following steps:

[0067] 1) Preparation of zirconia-containing composite tungsten powder

[0068] Dissolve 127.35kg of ammonium metatungstate and 2.79kg of zirconium nitrate in water respectively, and then mix the two solutions evenly to obtain a mixed solution; evaporate the mixed solution to dryness, and calcinate the obtained dry powder at a temperature of 450°C for 5 hours; put the calcined product in Put it into the push rod reduction furnace and divide it into two stages of reduction. The temperature of the first stage of reduction is 600°C, and the reduction time is 1.5 hours. The temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com