Automobile component conveyer

A technology for conveying devices and auto parts. It is applied in the direction of lifting devices, transportation and packaging, conveyors, etc. It can solve the problems of difficult automatic production, low labor efficiency, and difficult to transport to designated locations in batches, and achieve high positioning accuracy. High operating efficiency and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

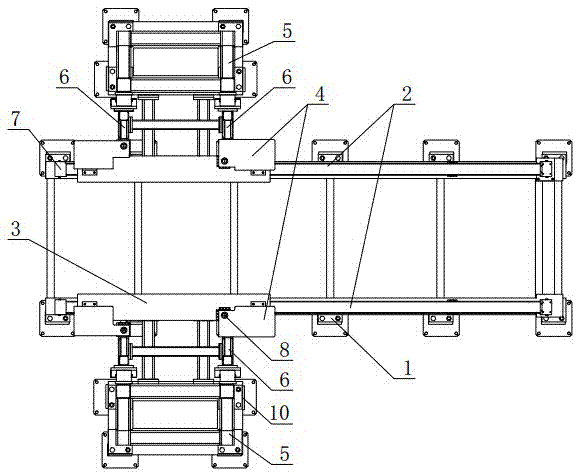

[0016] Such as figure 1 , figure 2 , image 3 and Figure 4 Shown, the present invention has provided the embodiment of a kind of automobile parts conveying device, for convenience description, with figure 1 The left and right direction in the figure is the longitudinal direction of the device, which includes a support base 1. There is a pre-embedded base on the workshop floor, and the height-adjustment bolt 11 is screwed on the pre-embedded base. The height-adjustment bolt 11 passes through the support base 1 and passes through the nut. The height position of the support base 1 is fixed, and the level of the support base 1 can be adjusted through the adjustment of the height adjustment bolt 11 and the locking of the nut on the bolt, so as to ensure the stability of the operation. The linear guide rail arranged vertically on the support base 1 2 slidingly connected with a sliding frame 3, the sliding frame 3 is positioned and inserted with a component delivery seat 4, spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com