Cylinder cover conveying device

A technology of a transport device and a cylinder head, applied in the field of auto parts production, can solve the problems of high cost of packaging, waste of firewood, oil and energy, unfavorable to energy conservation and environmental protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

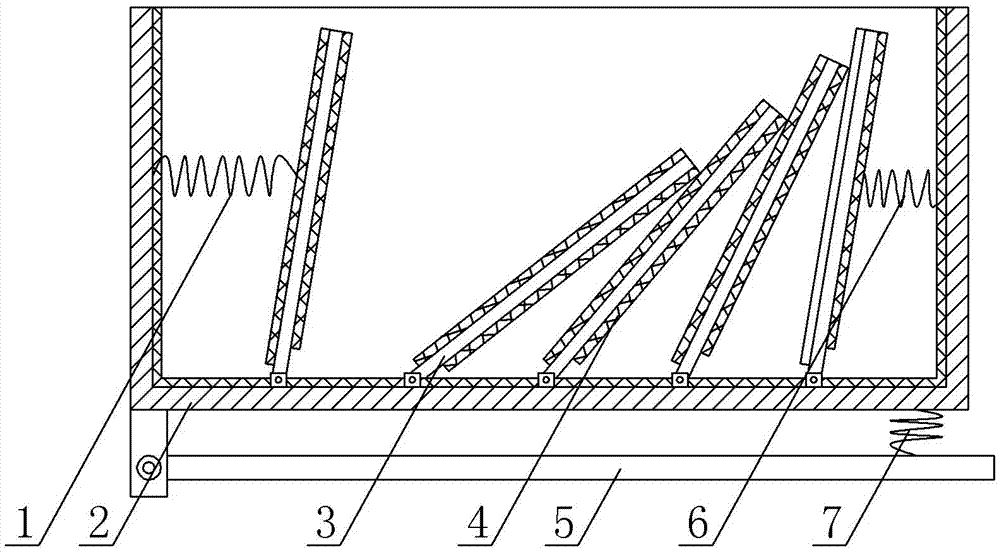

[0013] The reference signs in the drawings of the description include: the first compression spring 1 , the box body 2 , the partition plate 3 , the rubber pad 4 , the support plate 5 , the second compression spring 6 , and the third compression spring 7 .

[0014] The embodiment is basically as figure 1 Shown:

[0015] The cylinder head transportation device includes a box body 2, and the box body 2 includes a bottom surface and four side surfaces. A plurality of partition plates 3 are arranged in the box body 2 , and the partition plates 3 are movably hinged to the bottom surface of the box body 2 . Such as figure 1 As shown, a first compression spring 1 is fixed between the leftmost partition plate 3 in the box body 2 and the box body 2, and a first compression spring 1 is fixed between the rightmost partition plate 3 in the box body 2 and the box body 2. There is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com