Traction device of road-railer

A technology of road-rail dual-purpose vehicle and traction device, which is applied in traction connectors, vehicle components, transportation and packaging, etc., and can solve problems such as large degree of freedom of coupler shaking head, risk of derailment when passing small curves, and risk of unbalanced load in vehicle propulsion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

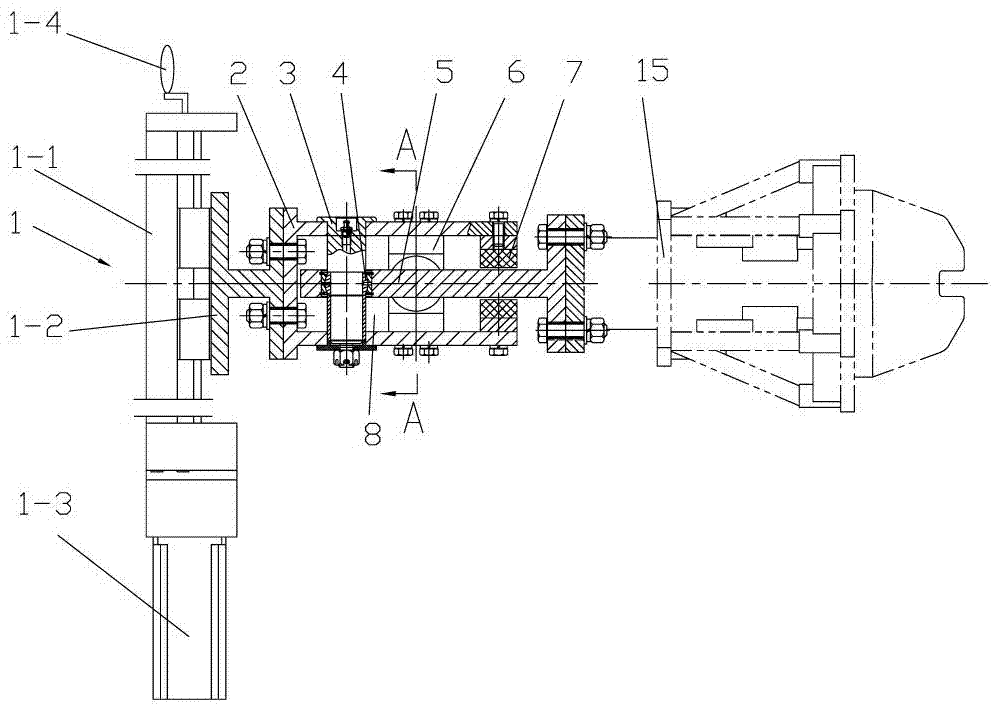

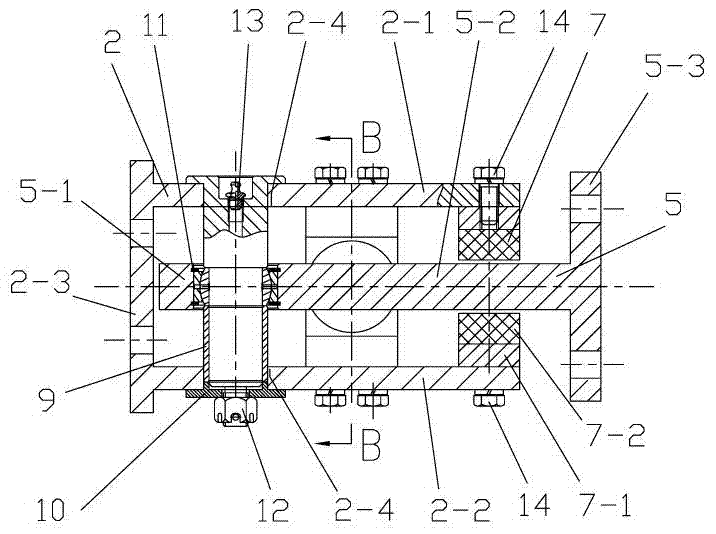

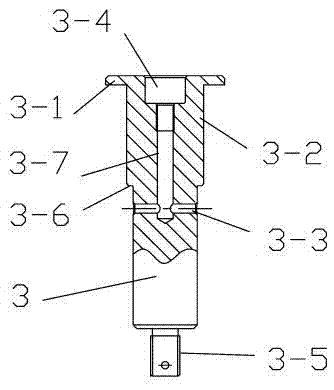

[0024] Such as Figure 1-5 As shown, a traction device for public and railway vehicles of the present invention includes a linear guide rail module 1, a fifth wheel 2, a center pin 3, a draw bar 5, a lateral stopper 6 and a vertical stopper 7, and the fifth wheel 2 is fixedly connected with the linear guide rail module 1, the traction seat 2 has an installation space 8, the center pin 3 passes through the installation space 8 and is axially fixed on the traction seat 2, and one end 5-1 of the traction rod 5 passes through the joint The bearing 4 is rotatably mounted on the center pin 3 pin body located in the installation space 8, and the other end of the drawbar 5 stretches out of the installation space 8 and has a coupler connecting plate 5-3 for connecting the coupler. The stopper 6 and the vertical stopper 7 are fixed in the installation space 8 of the traction seat 2, and the shaft 5-2 of the drawbar 5 can be in contact with the lateral stopper 6 and the vertical stopper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com