Biomass raw material screening device

A biomass raw material and screening device technology, which is applied in the fields of sieving, solid separation, grain processing, etc., can solve the problems of the impact of finished product quality, raw material purity is not high, and biomass fuel is mixed with impurities, etc. Good effect, scientific design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

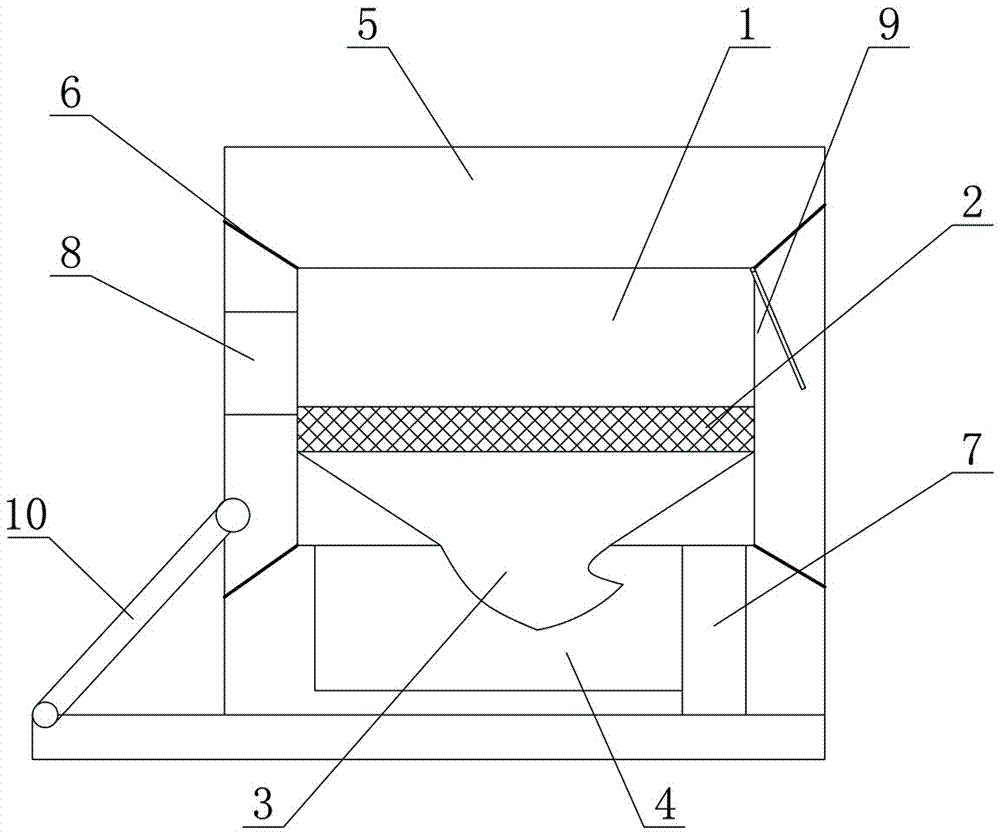

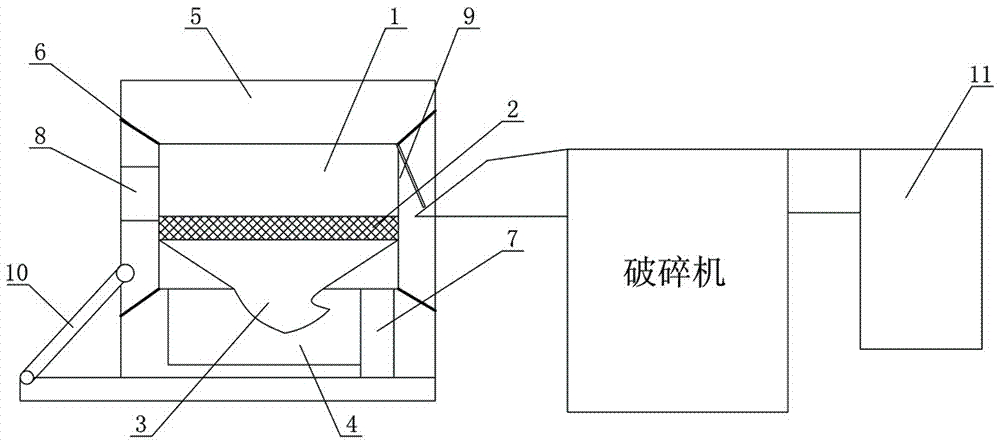

[0021] Such as figure 1 and figure 2 Shown, a kind of biomass raw material screening device, it comprises the first screening machine that is connected at the feed port of crusher, and described first screening machine comprises vibrating screen box, the net-shaped thing that is installed in described vibrating screen box The tray 2, the funnel slideway 3 located under the mesh storage tray 2 and the accommodation chamber 4 connected to the lower outlet of the funnel slideway 3, the vibrating screen box includes a box body 1, a bracket 5, connected to the The elastic support 6 between each corner of the box body 1 and the bracket 5, the vertical vibration device 7 for driving the box body 1 to vibrate vertically, and the lateral vibration device 8 for driving the box body 1 to vibrate laterally. The mesh storage tray 2 is conical. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com