Tooling for assembling circuit breaker energy storage components and assembly method thereof

A technology of energy storage components and assembly methods, applied in the field of assembly tooling, to achieve the effects of low manufacturing cost, high work efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

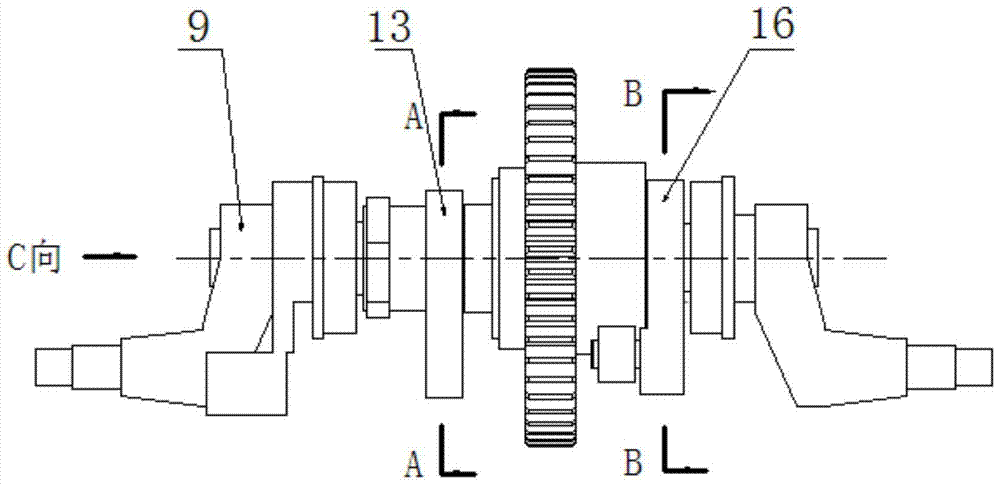

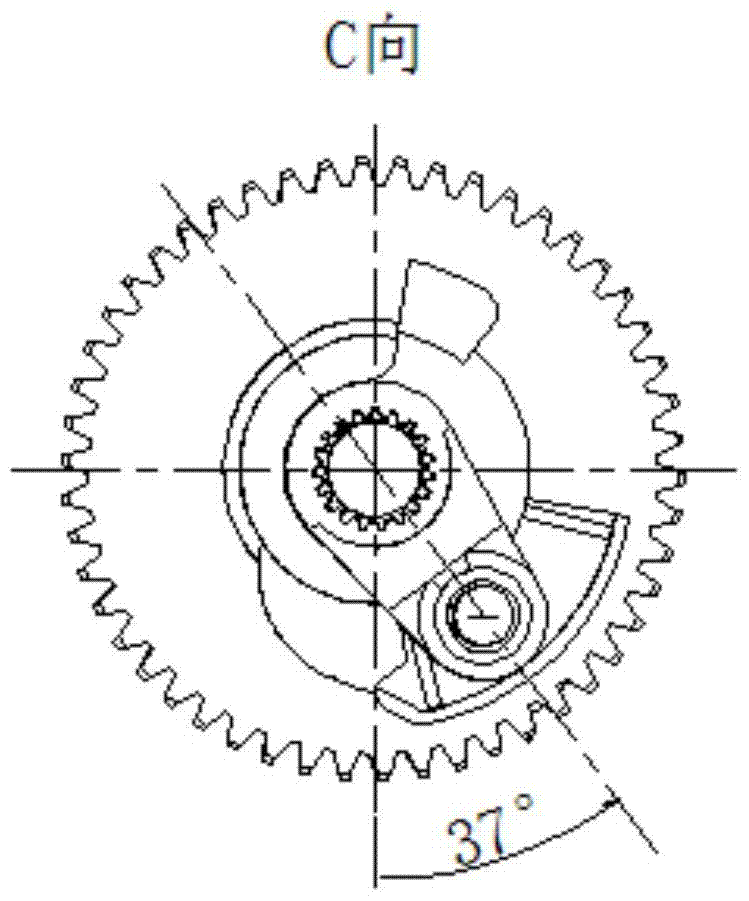

[0023] Depend on figure 1 It can be seen that the spring toggle arm 9, the cam 13, and the energy storage toggle arm assembly 16 must be assembled at a certain angle before the circuit breaker can work normally. Figure 3-5 shown.

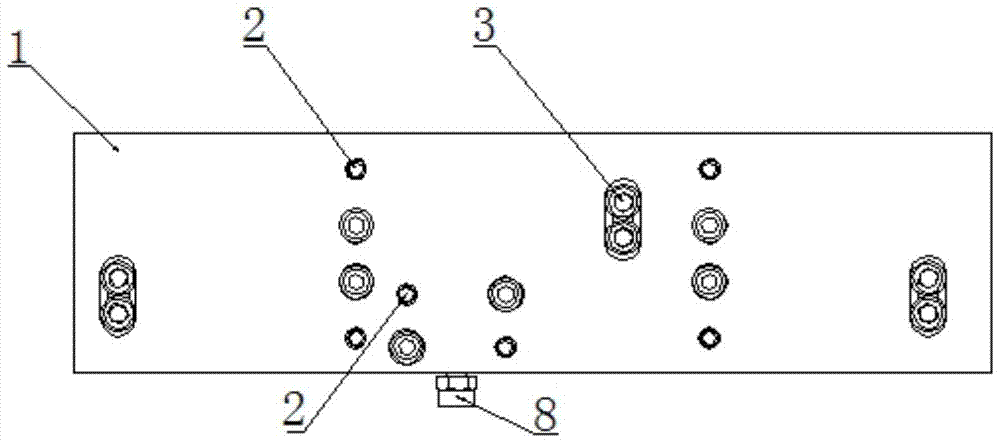

[0024] The tooling used for assembling the energy storage components of the circuit breaker includes a base plate 1 and a limit block 4 fixed on the base plate 1, a support plate 5, a movable pin 6 and a stopper 7, the base plate 1 plays a supporting role, and three identical limit blocks 4 respectively adopt two screws 3 to locate on the bottom plate 1, two identical support plates 5 are positioned on the bottom plate 1 by two positioning pins 2 and two screws 3, and the two positioning pins 2 and two screws 3 will block Block 7 is fixed on base plate 1 .

[0025] The two supporting plates 5 are used to support the first bearing 11 and the second bearing 11 , and the upper end surfaces of the supporting plates 5 are provided with grooves for su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com