Elastic coupling for spline shaft

An elastic coupling and spline shaft technology, applied in elastic couplings, couplings, mechanical equipment and other directions, can solve the problems of accelerated spline wear, impact, large concentricity, etc., to ensure concentricity, reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

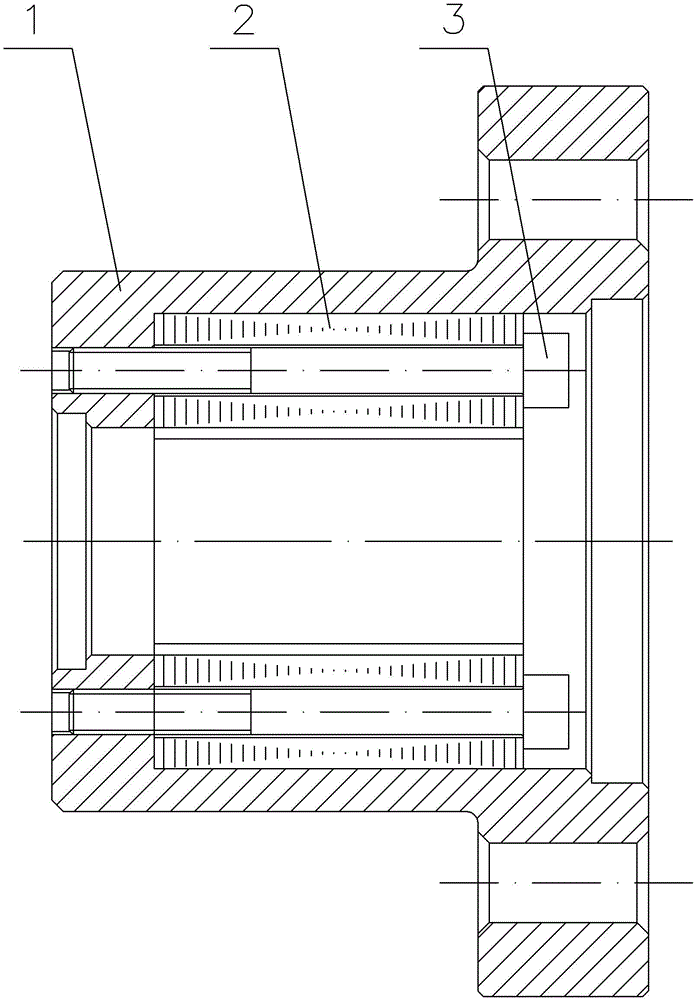

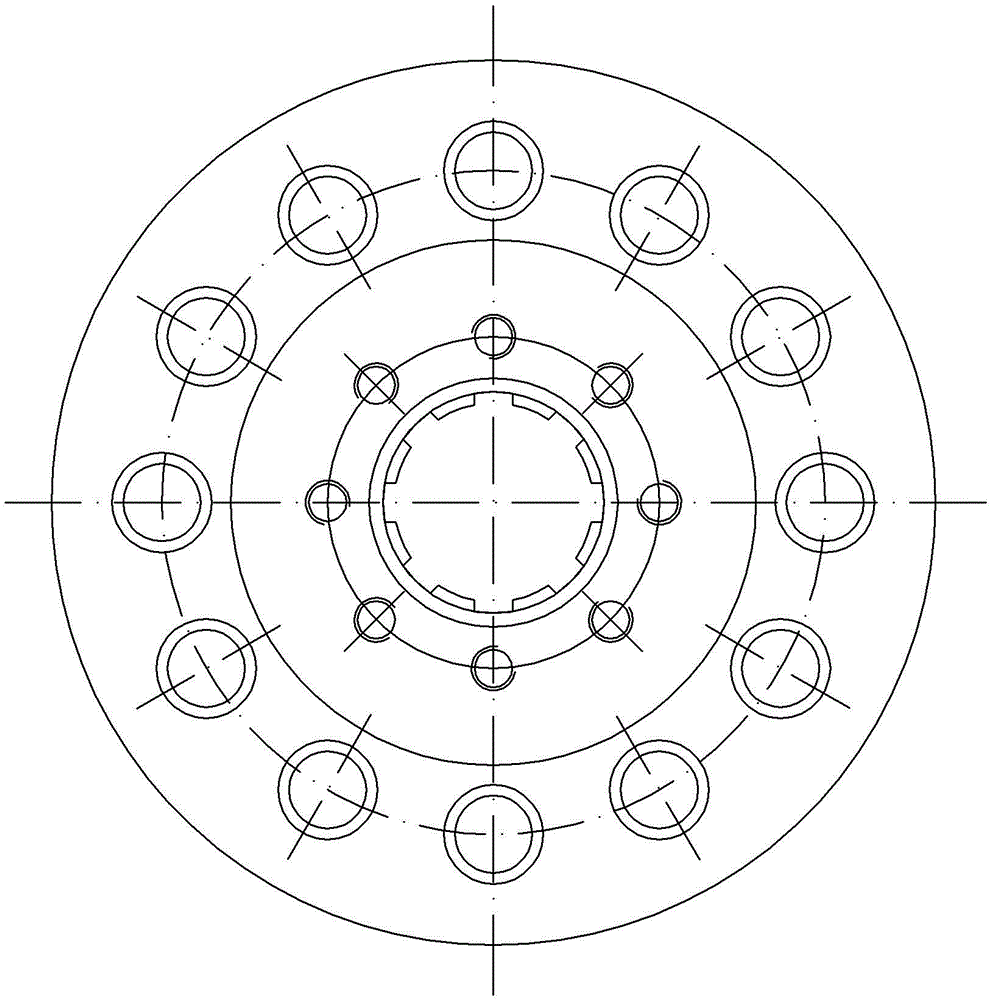

[0016] The reference signs in the accompanying drawings of the specification include: a flange 1 , a spline sleeve 2 , and a screw 3 .

[0017] This example figure 1 , figure 2 Shown: Elastic coupling for spline, including flange 1, spline sleeve 2 and screw 3, spline sleeve 2 is stacked together with several 1 mm thick ring-shaped steel plates, and each ring-shaped steel plate has a There are through holes distributed in the circumferential direction, and the through holes on each annular steel plate form a long through hole for it when stacking. The screws 3 pass through these long through holes and extend into the bottom surface of the counterbore on the flange 1 And through the threaded hole on the bottom surface, it is fixedly connected with the flange plate 1, and at the same time, the entire spline sleeve 2 is pressed on the flange plate 1; the overlapping coeff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com