Exhaust assembly of water-drive and non-electric exhaust fan

An electric exhaust fan and water drive technology, which is applied in hydropower, mechanical equipment, machines/engines, etc., can solve problems such as safety accidents, poor ventilation effects, and inability to circulate fire-fighting water, so as to improve the conversion rate and exhaust air The effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

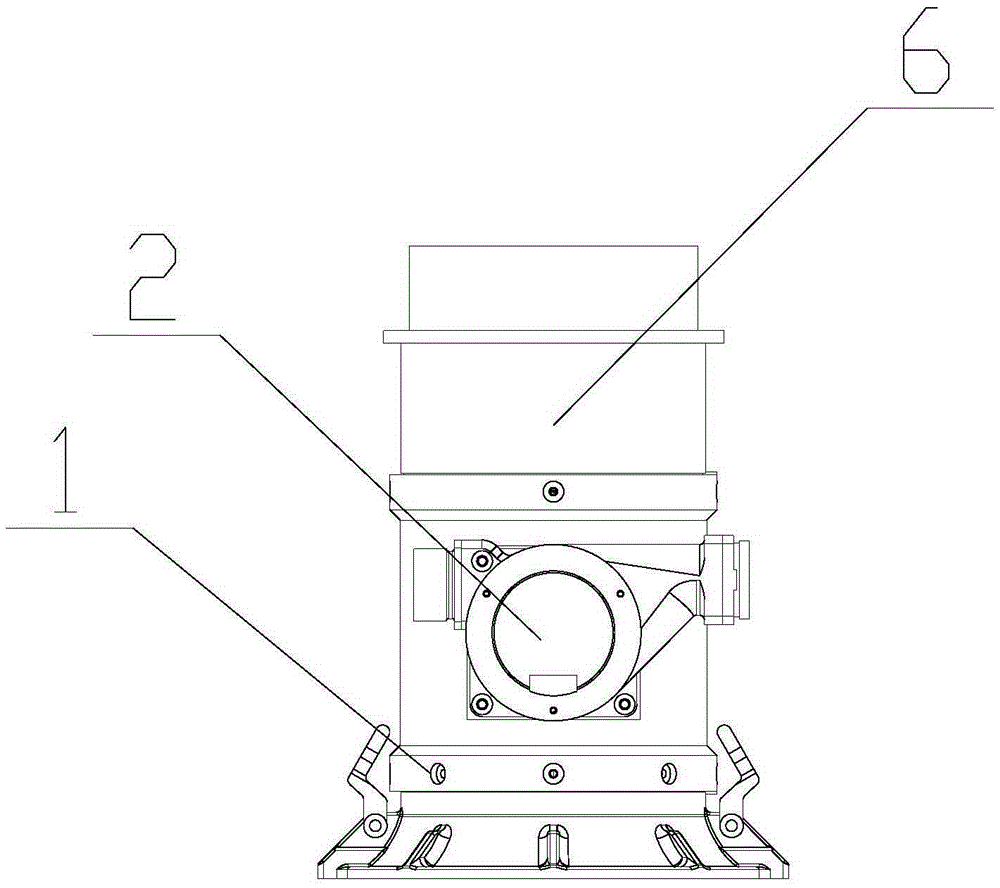

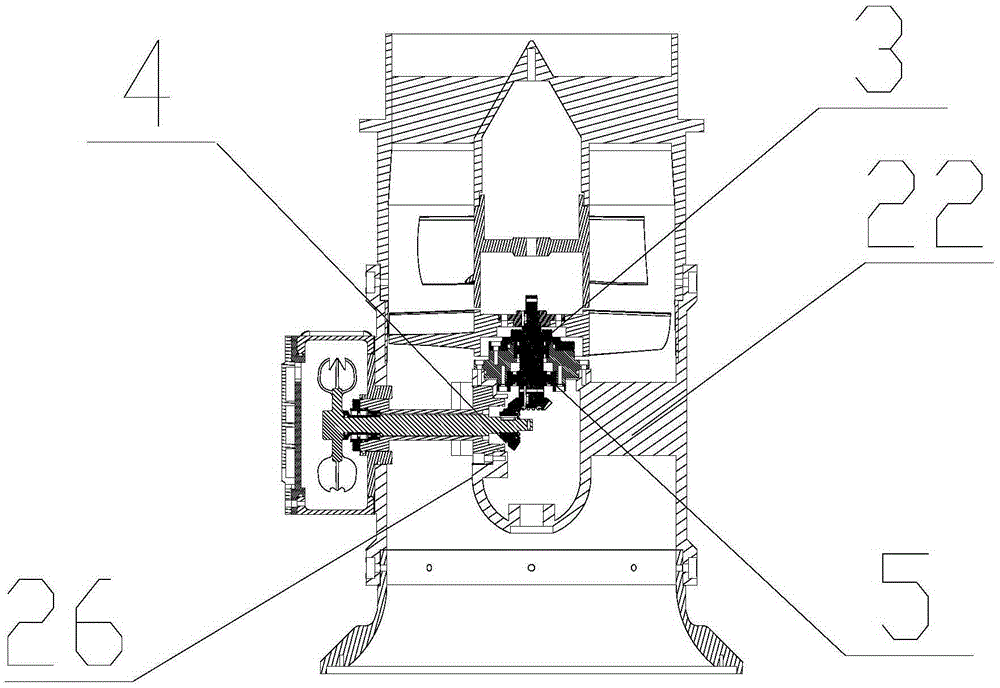

[0024] Referring to the accompanying drawings, the water-driven non-electric exhaust fan includes a casing, a water-drive assembly is provided on one side of the casing, and a transmission assembly is provided inside the casing, and the water-drive assembly is provided with a The transmission device is connected with the transmission assembly, and the upper end of the shell is provided with an exhaust assembly.

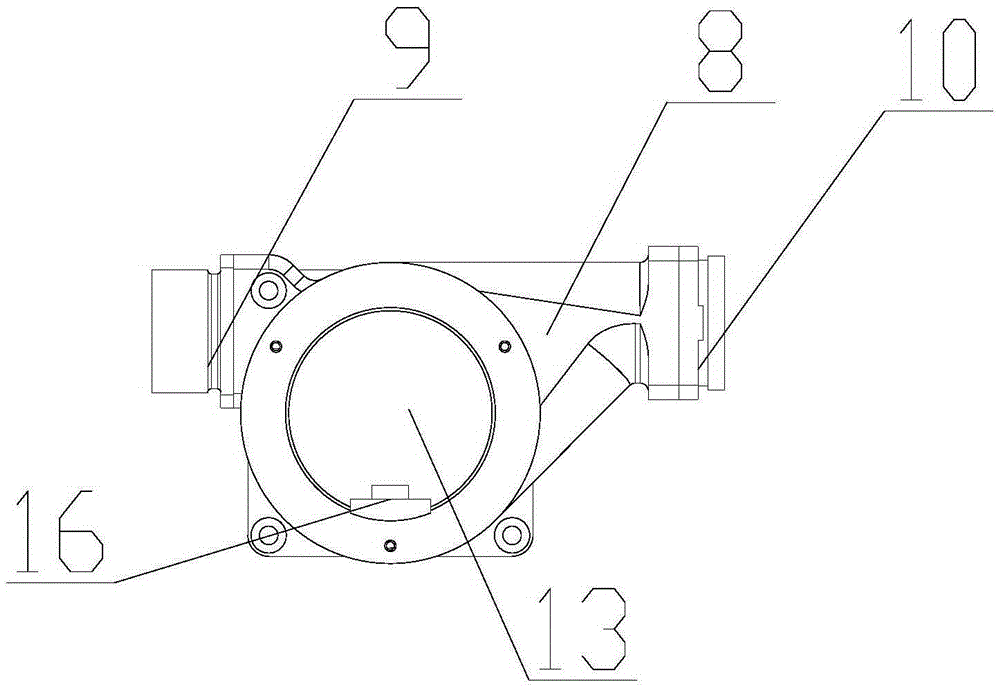

[0025] Preferably, the water drive assembly includes a turbine housing, a water drive cavity is provided in the turbine housing, a water inlet is provided at one end of the turbine housing, and a water outlet is provided at the other end of the turbine housing , the water drive cavity is provided with a concave impeller group, the concave impeller set is provided with a rotating shaft, one side of the water drive cavity communicates with the outside world, and one side of the water drive cavity is provided with With cover.

[0026] Preferably, one side of the water f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com