Multi-stage large-flow sliding vane pump

A large flow, sliding vane pump technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of affecting the service life of shafts and bearings, increasing manufacturing costs, and unstable medium pulsation, etc., to improve work efficiency and service life, prolong service life, smooth medium pulsation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

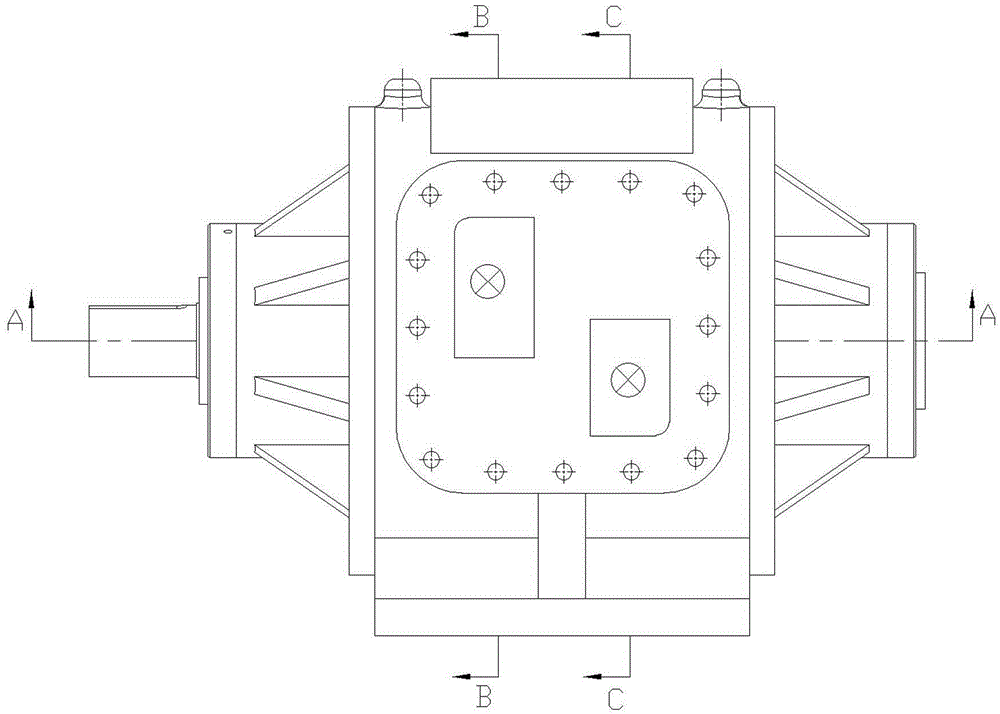

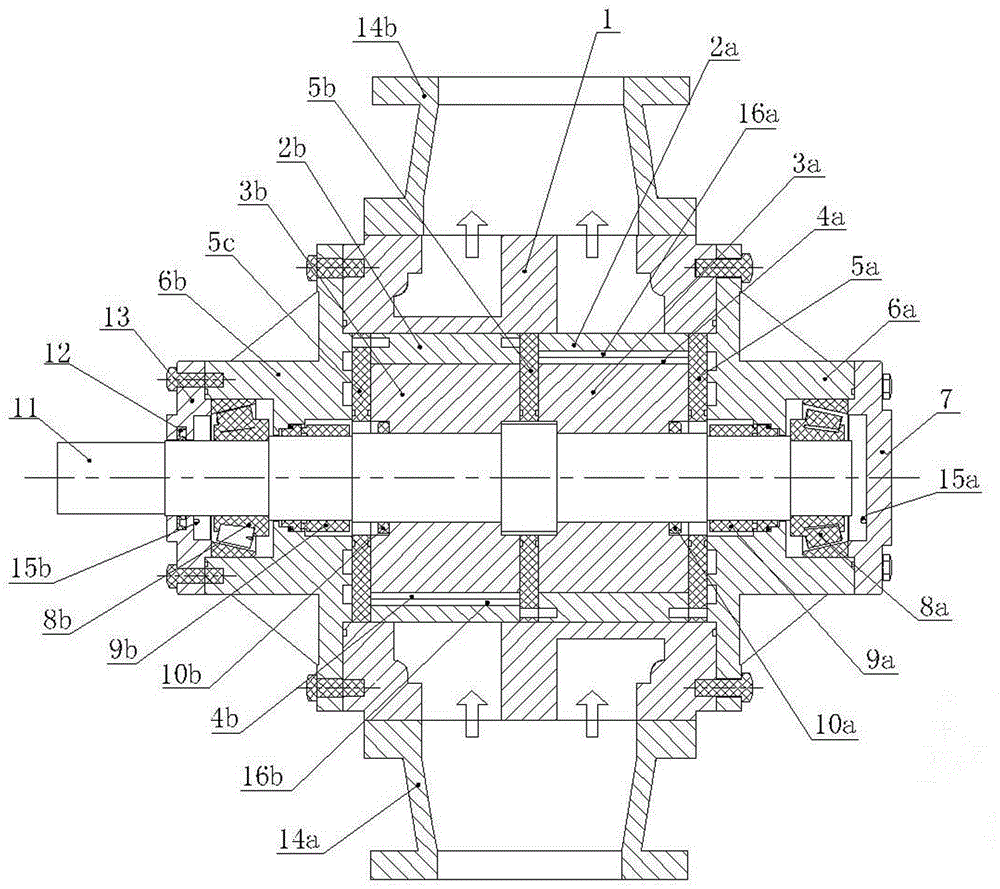

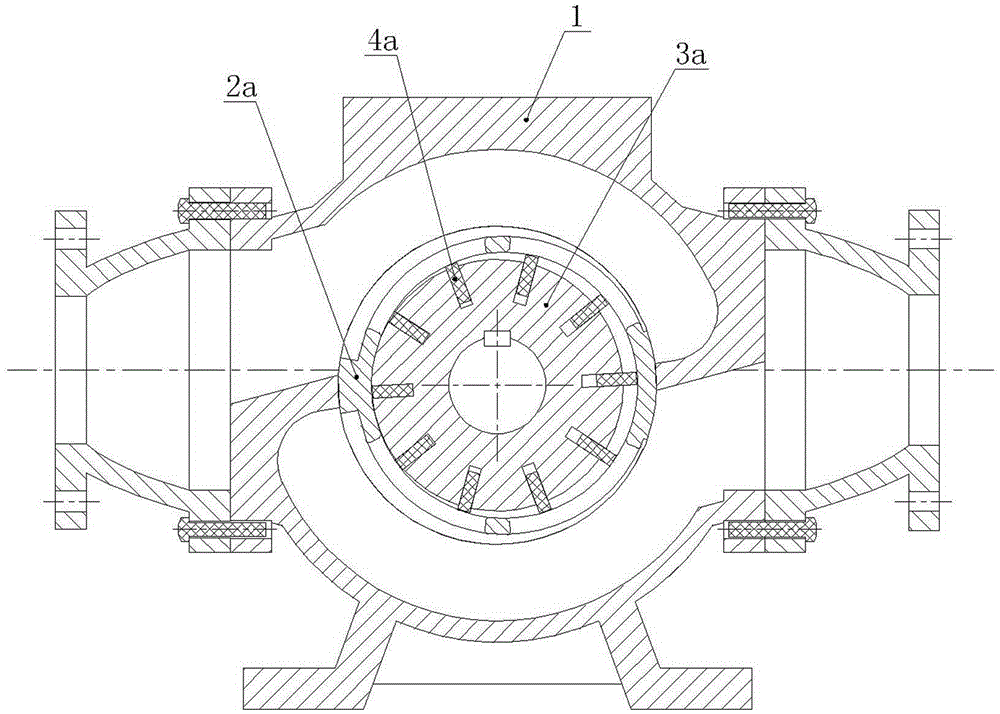

[0017] See attached figure 1 , attached figure 2 , a multi-stage high-flow sliding vane pump, including pump body (1), stator (2a / 2b), rotor (3a / 3b), sliding vane (4a / 4b), thrust plate (5a / 5b), Pump cover (6a / 6b), bearing rear gland (7), tapered roller bearing (8a / 8b), mechanical seal (9a / 9b), adjusting nut (10a / 10b), shaft (11), lip seal (12), bearing front gland (13), inlet and outlet reducing diameter (14a / 14b). The two stators (2a / 2b) with eccentric inner cavity are coaxial and 0 The phase difference is installed on the inner wall of the pump body (1), the two slotted rotors (3a / 3b) in the stator (2a / 2b) are coaxially installed on the shaft (11), and the thrust plate (5a / 5b) connects the two The rotors (3a / 3b) are separated, and the slides (4a / 4b) are slidably placed in the radial grooves of the rotors (3a / 3b), and the rotors (3a / 3b) pass through the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com